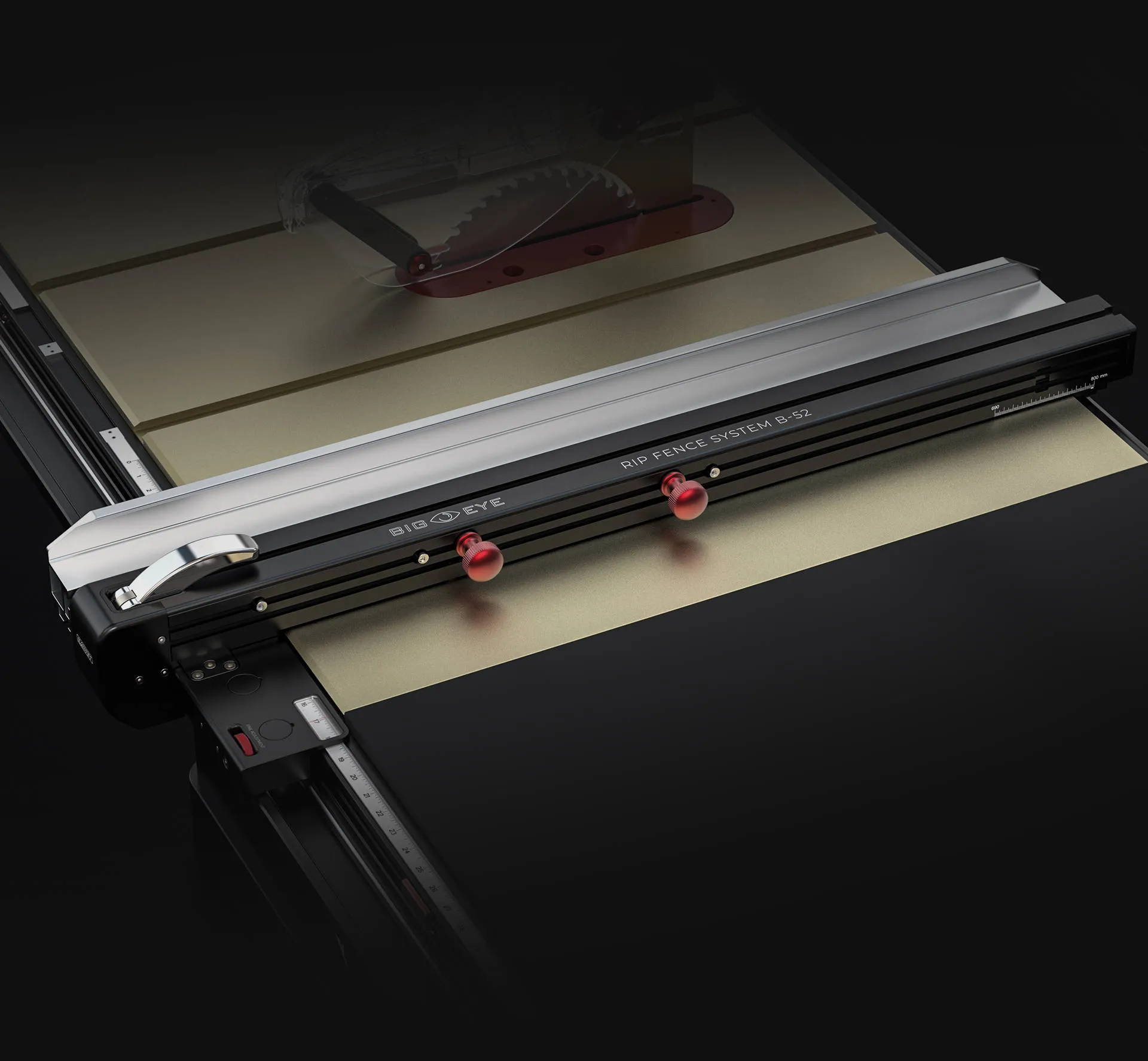

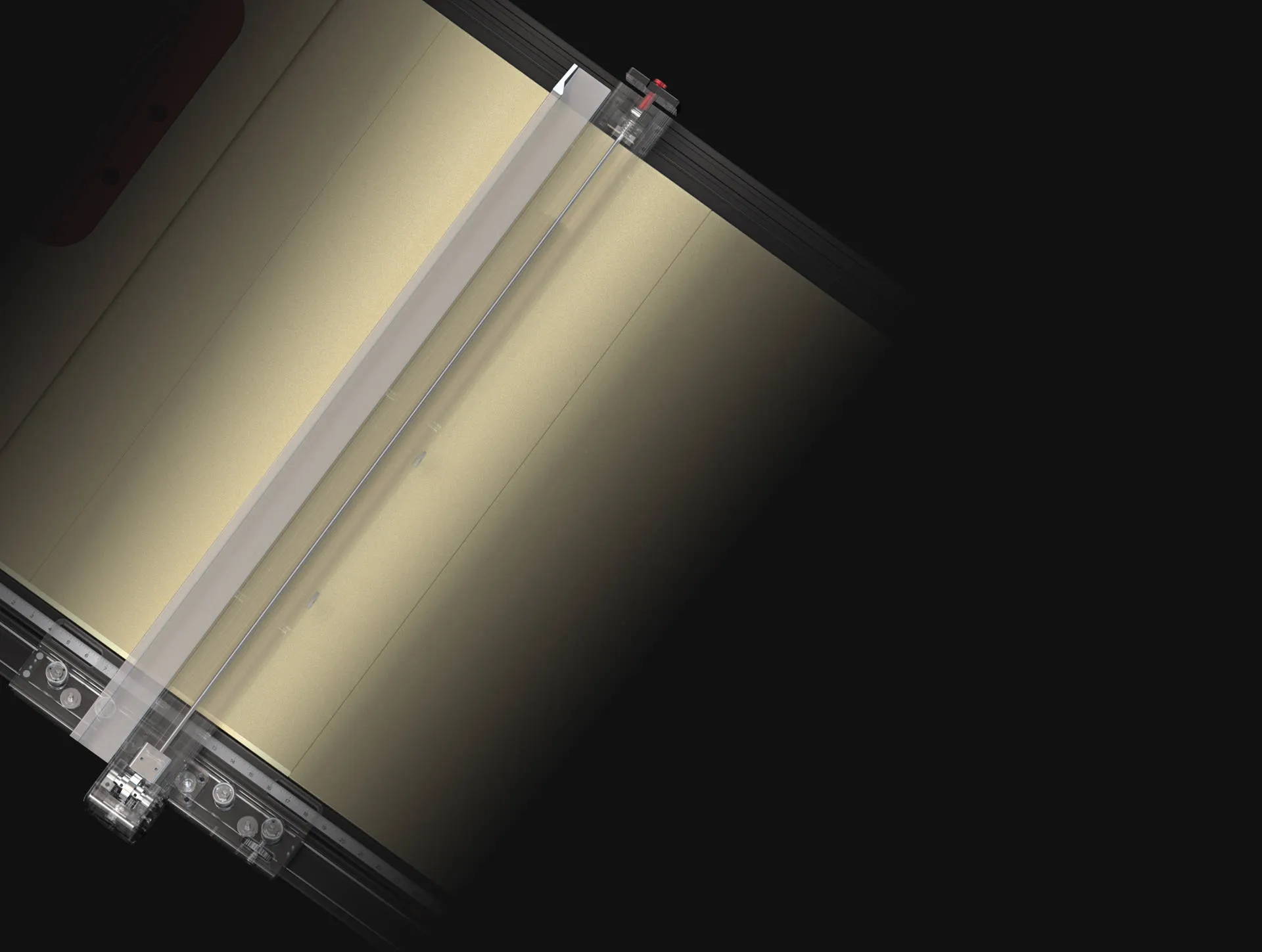

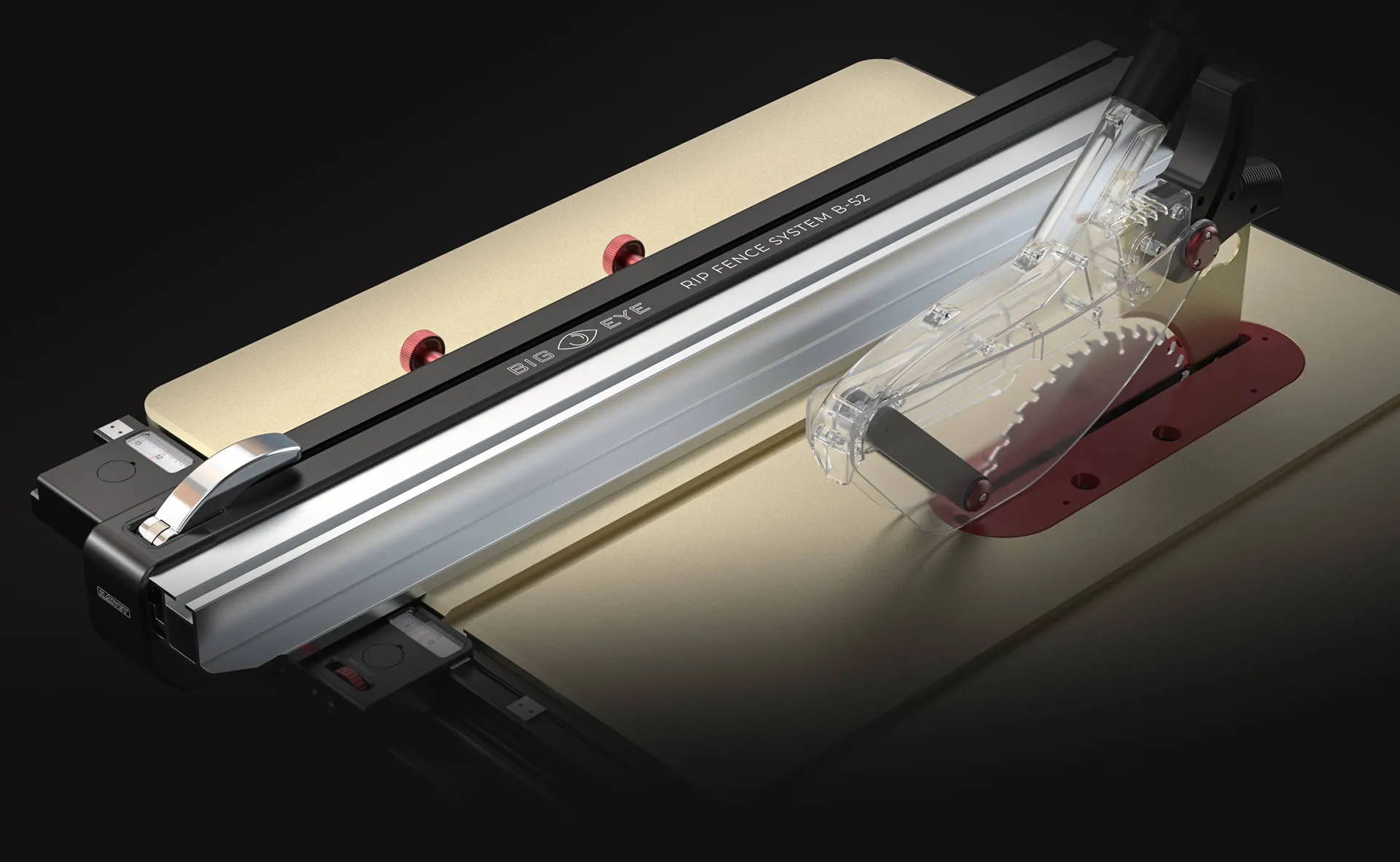

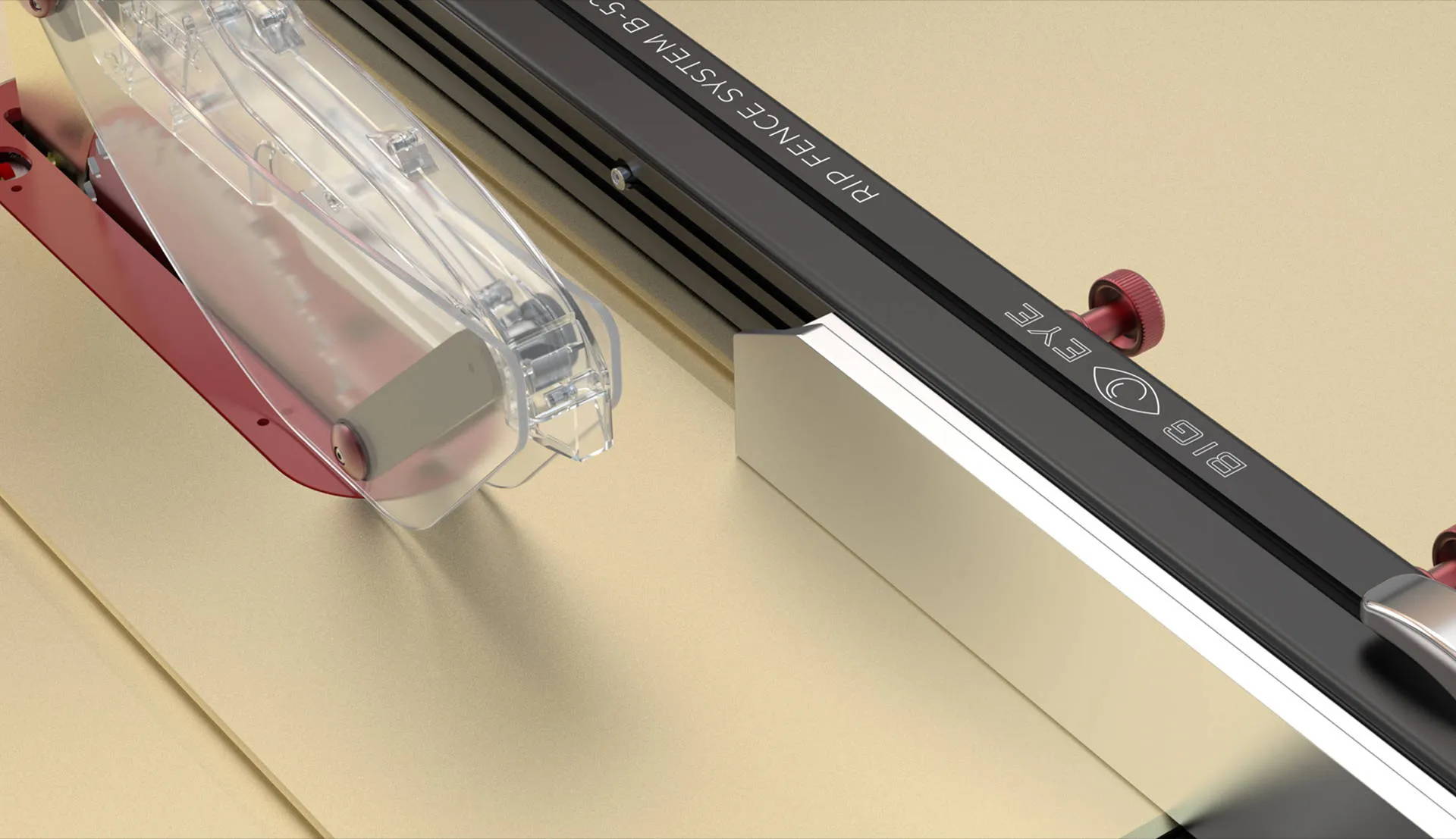

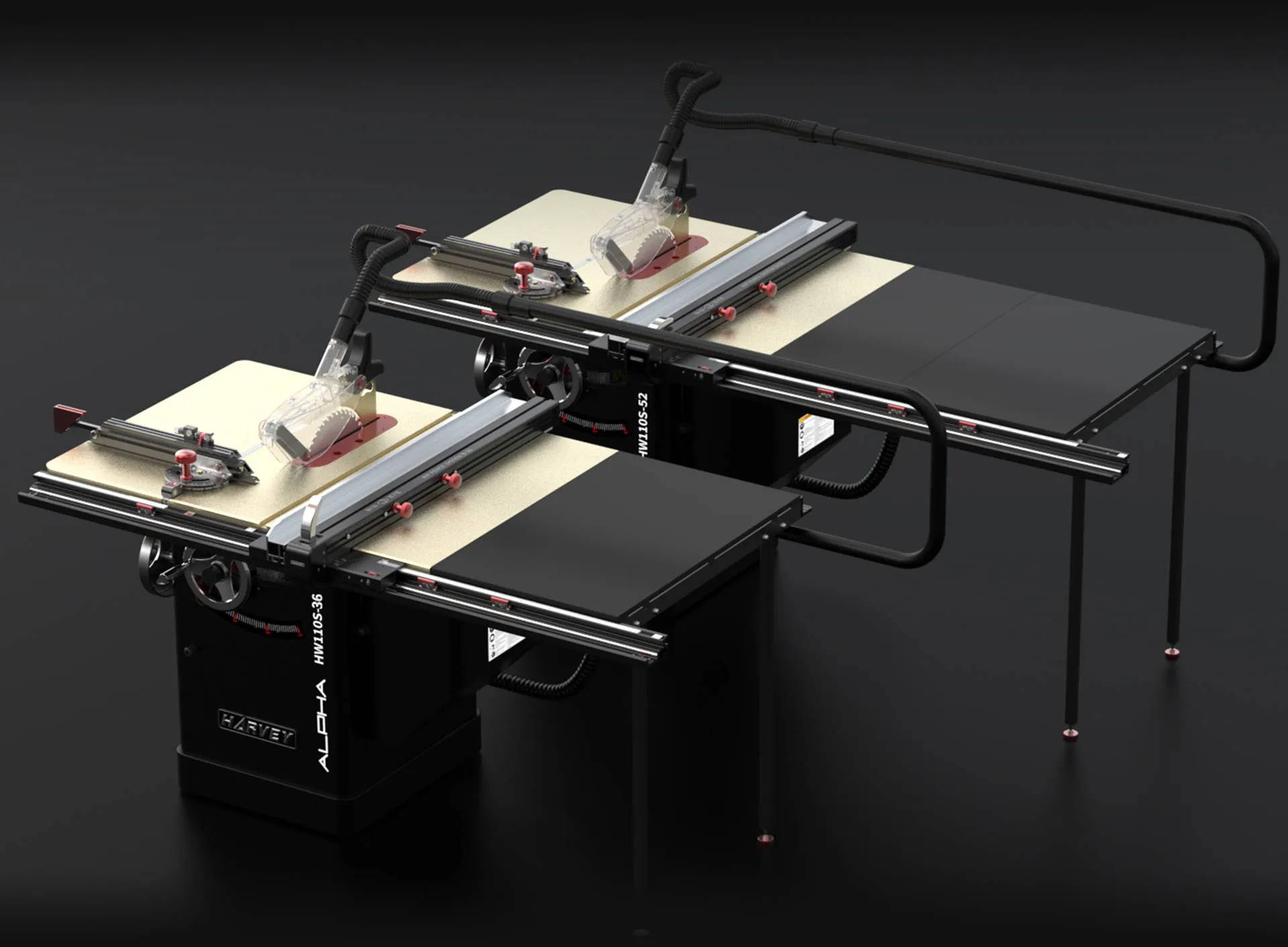

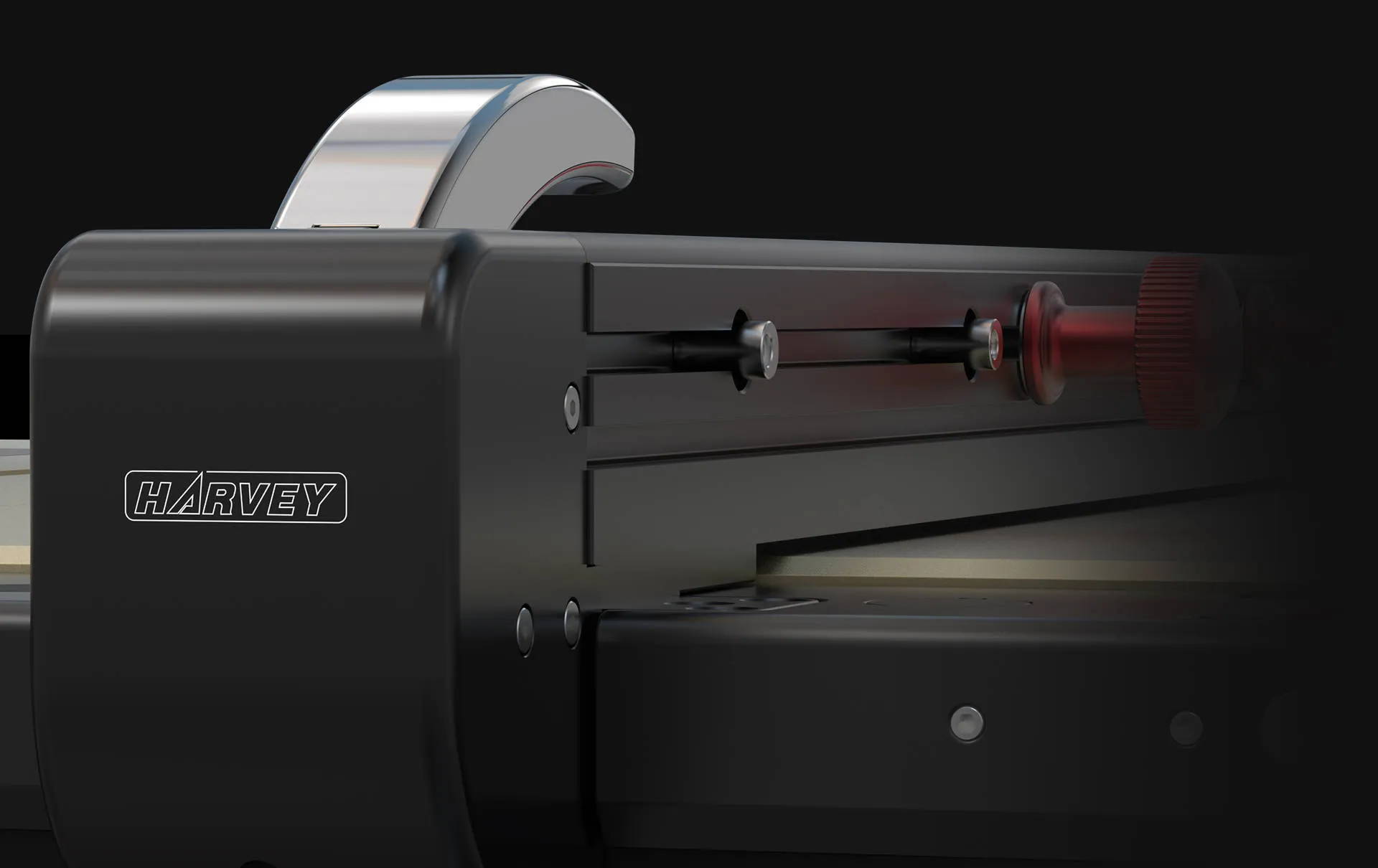

Overall, the fit and finish on this product is incredible. Once everything is attached properly and aligned, it is Rock solid. I am incredibly satisfied with the quality and craftsmanship of this fence.

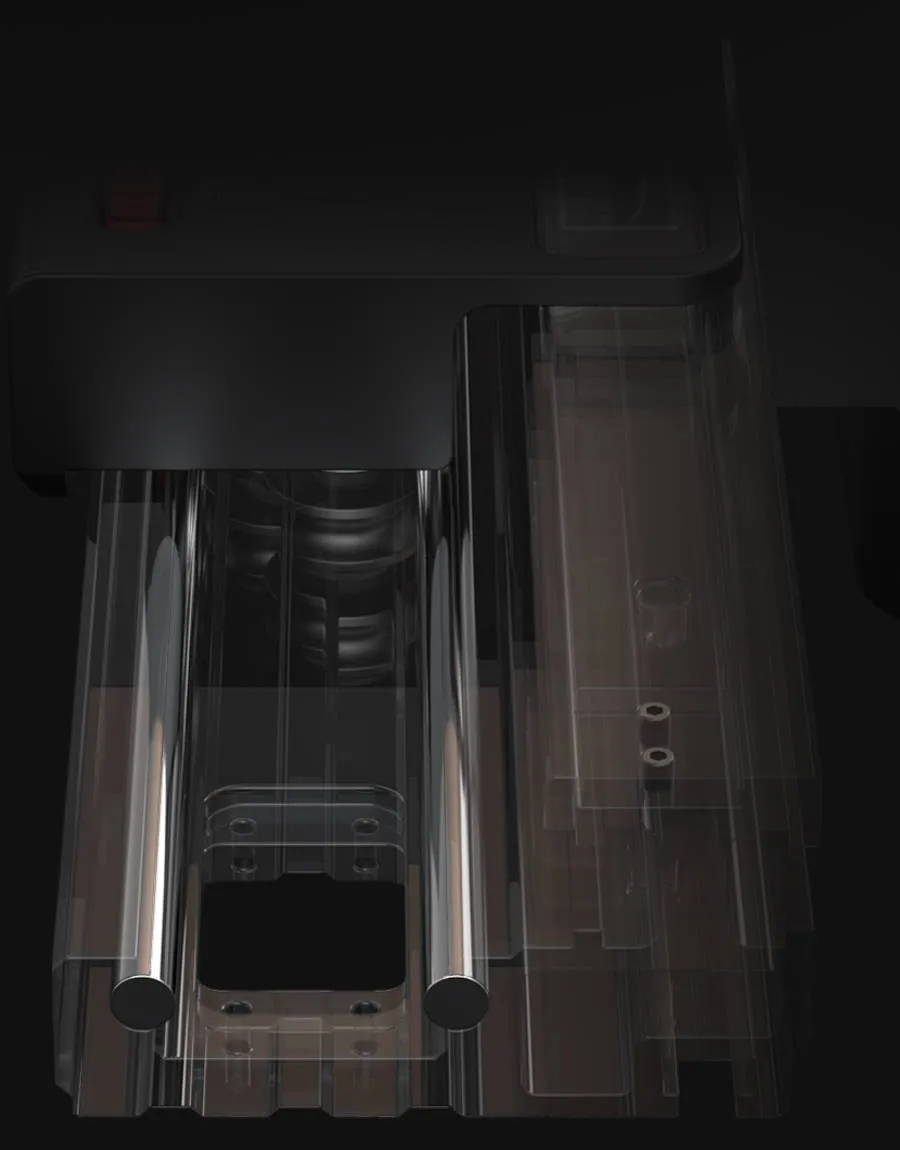

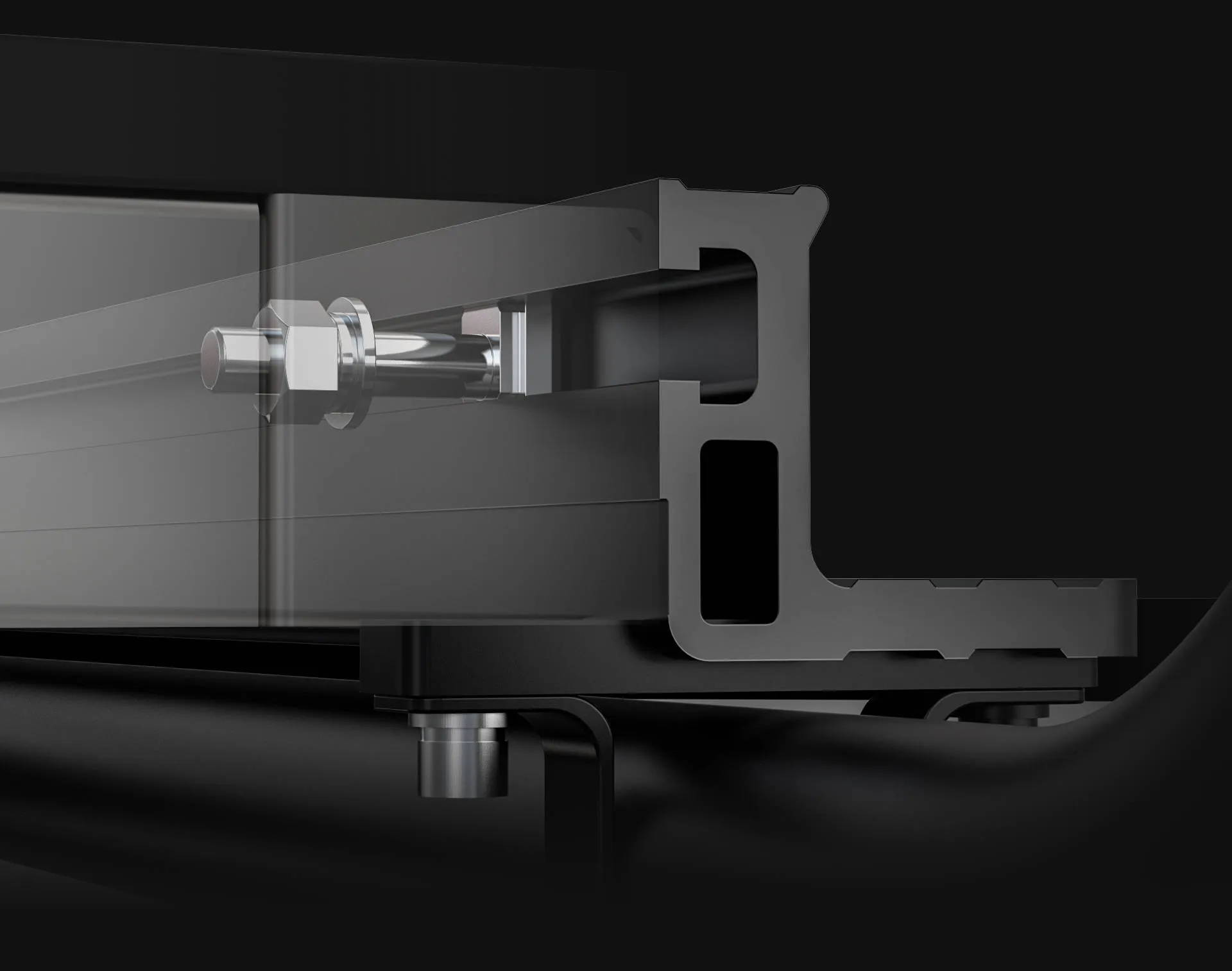

That being said however, I did have some issues during installation. It may be due to the fact that my saw is an older sawstop, from around 2004 to 2010, but I had a significant amount of difficulty getting everything installed in aligned. The mounting positions on my saw did not match up to the mounting holes on the fence. I ended up having to drill out the mounting holes in the table quite significantly in order to accommodate this fence, as the mounting position on this older saw placed the hardware much too close to the top of the table surface, preventing proper fitment.

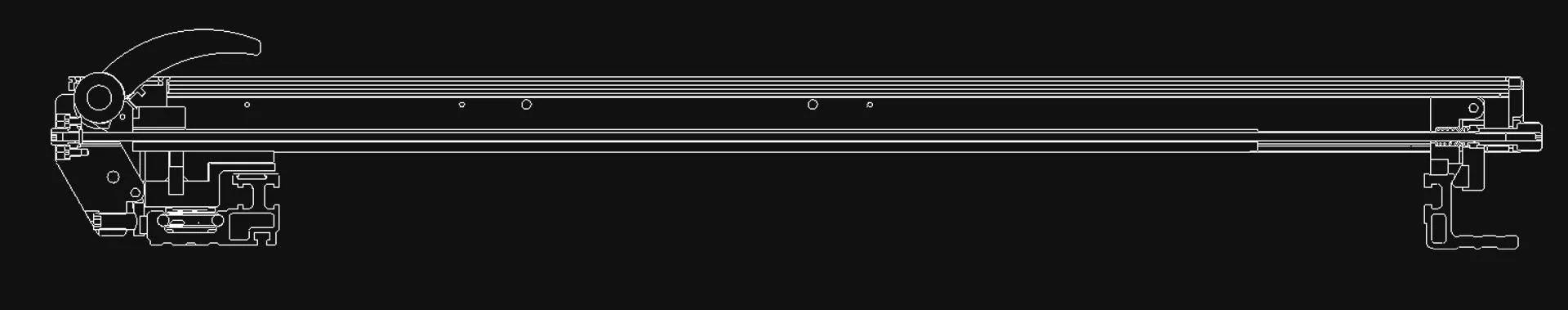

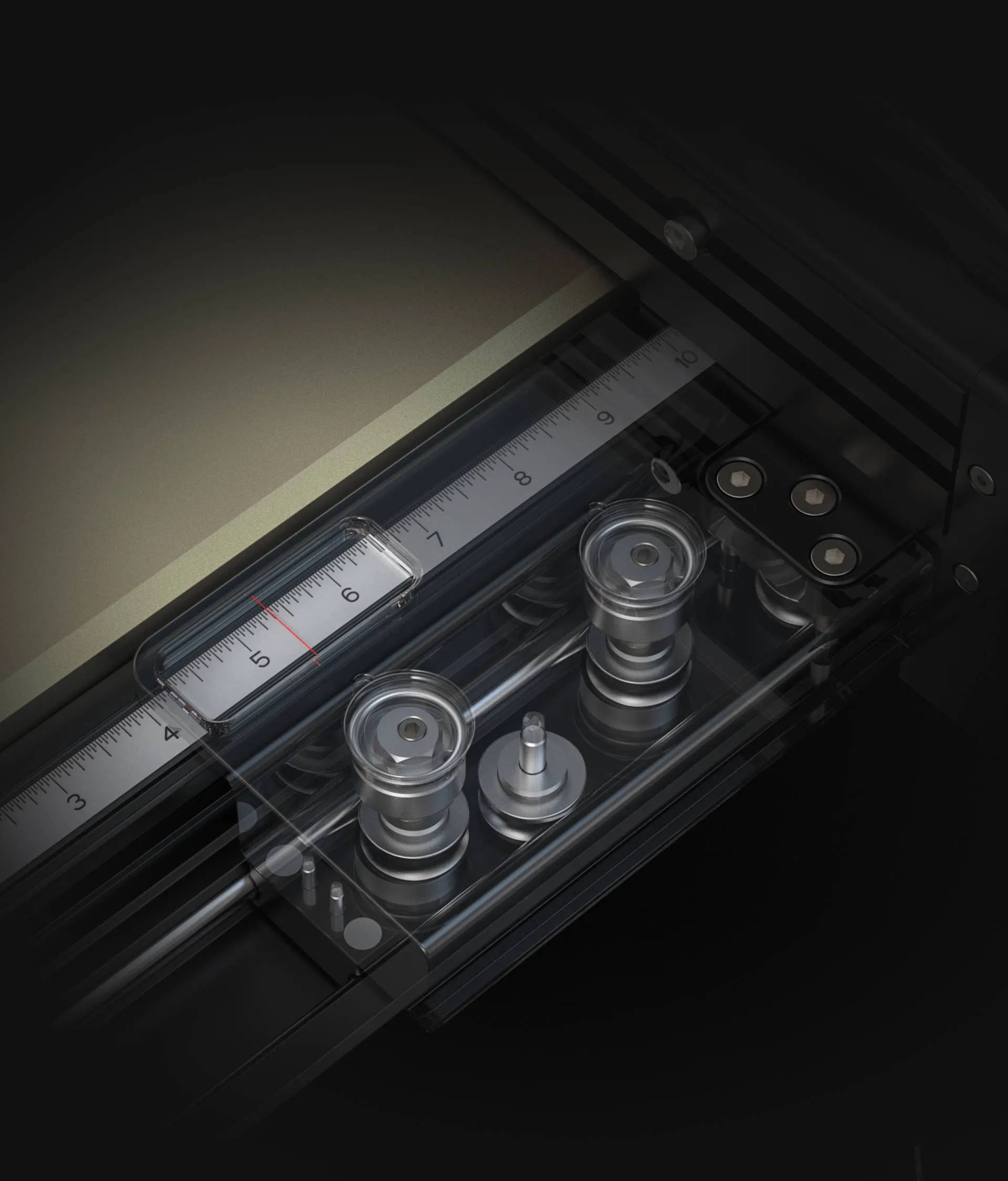

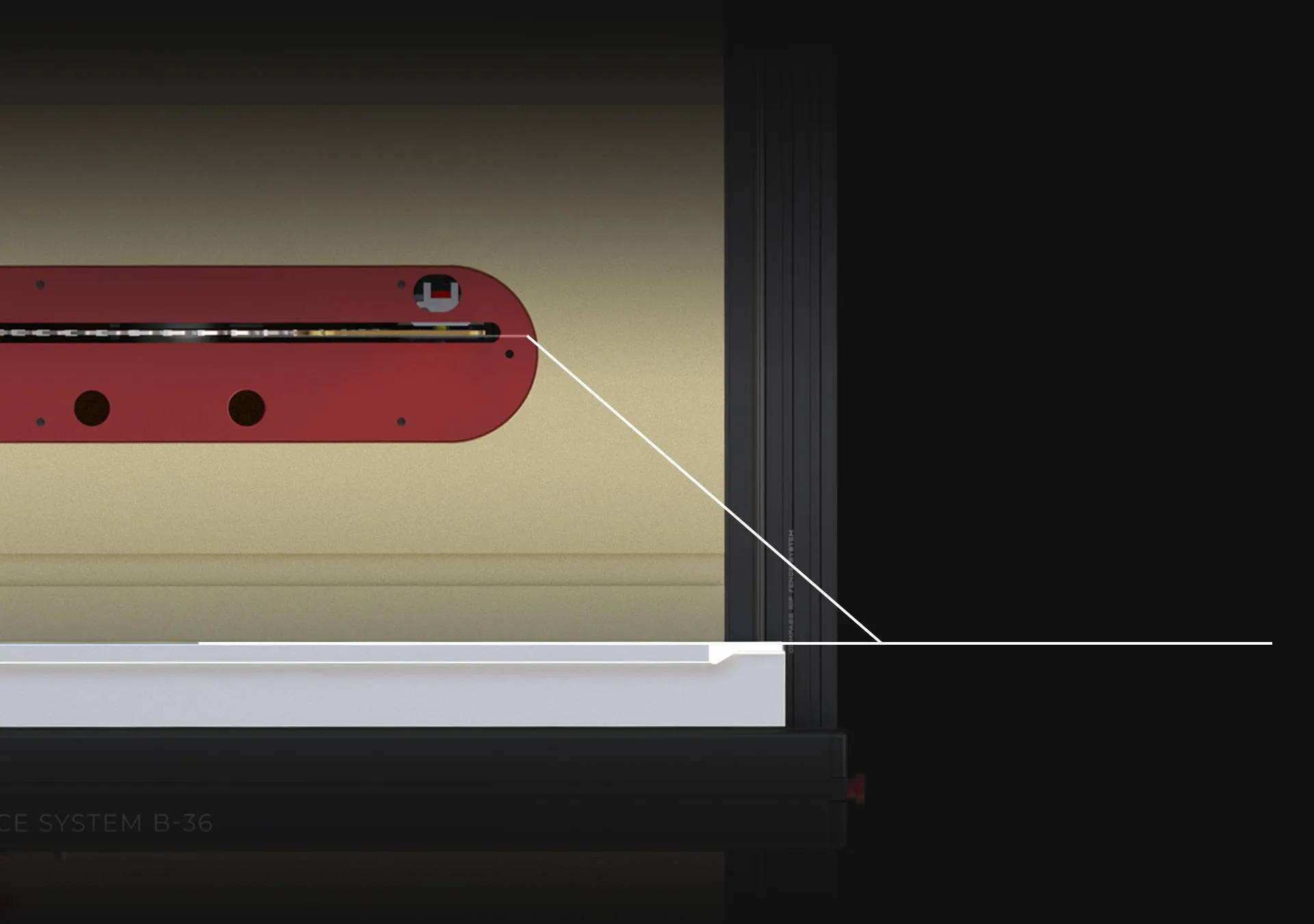

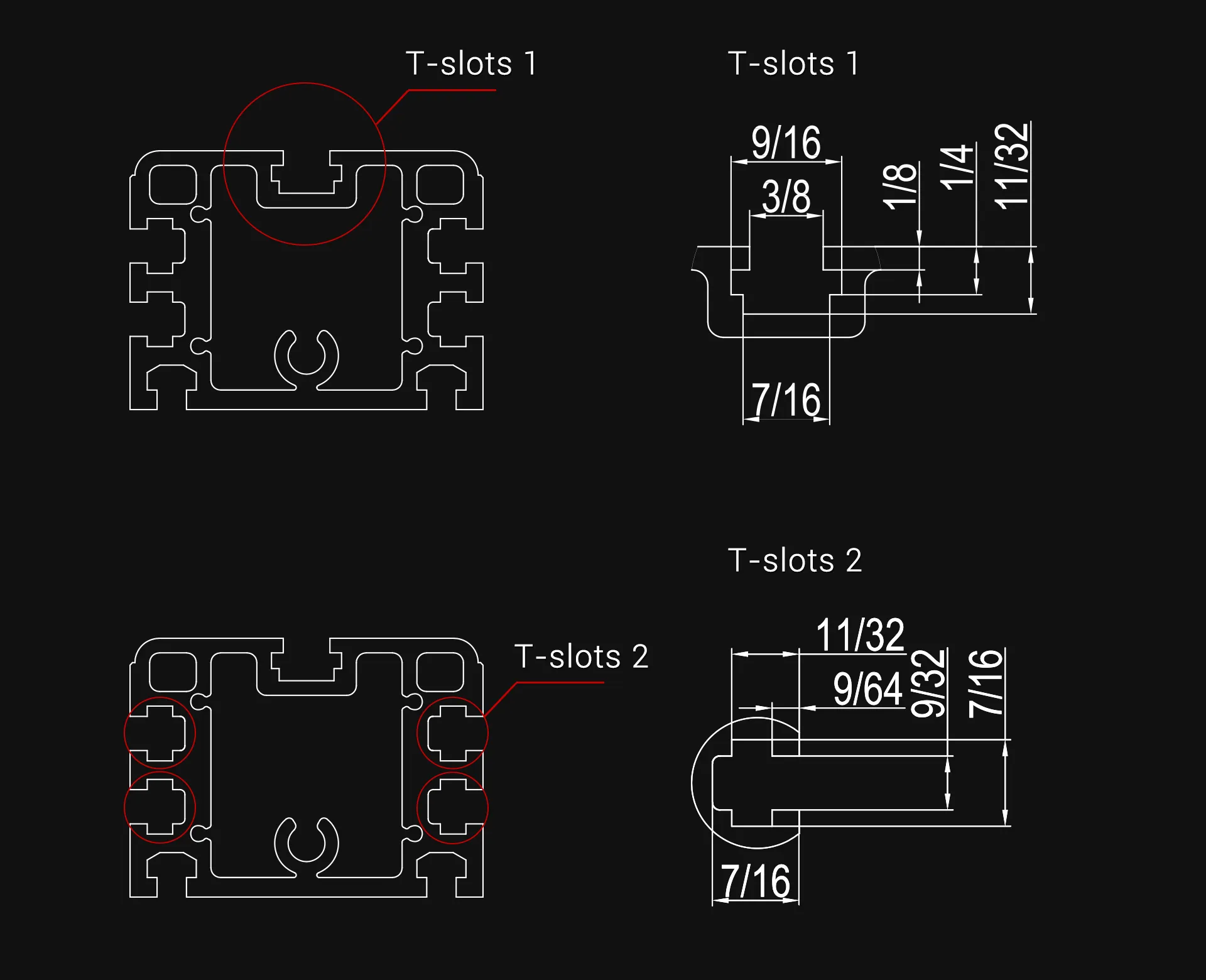

Furthermore, the instructions were a bit unclear in a few different places. The instructions indicate that you must have 11.5 mm of clearance from the top of the table to the top of the fence rail, but they don't explain why. Turns out, this is to ensure that the top of the rail clears the bottom of the miter slot, and there is even a fancy laser cut plastic alignment block to ensure this. This was not covered in the instructions, and I only figured it out by happenstance afterwards.

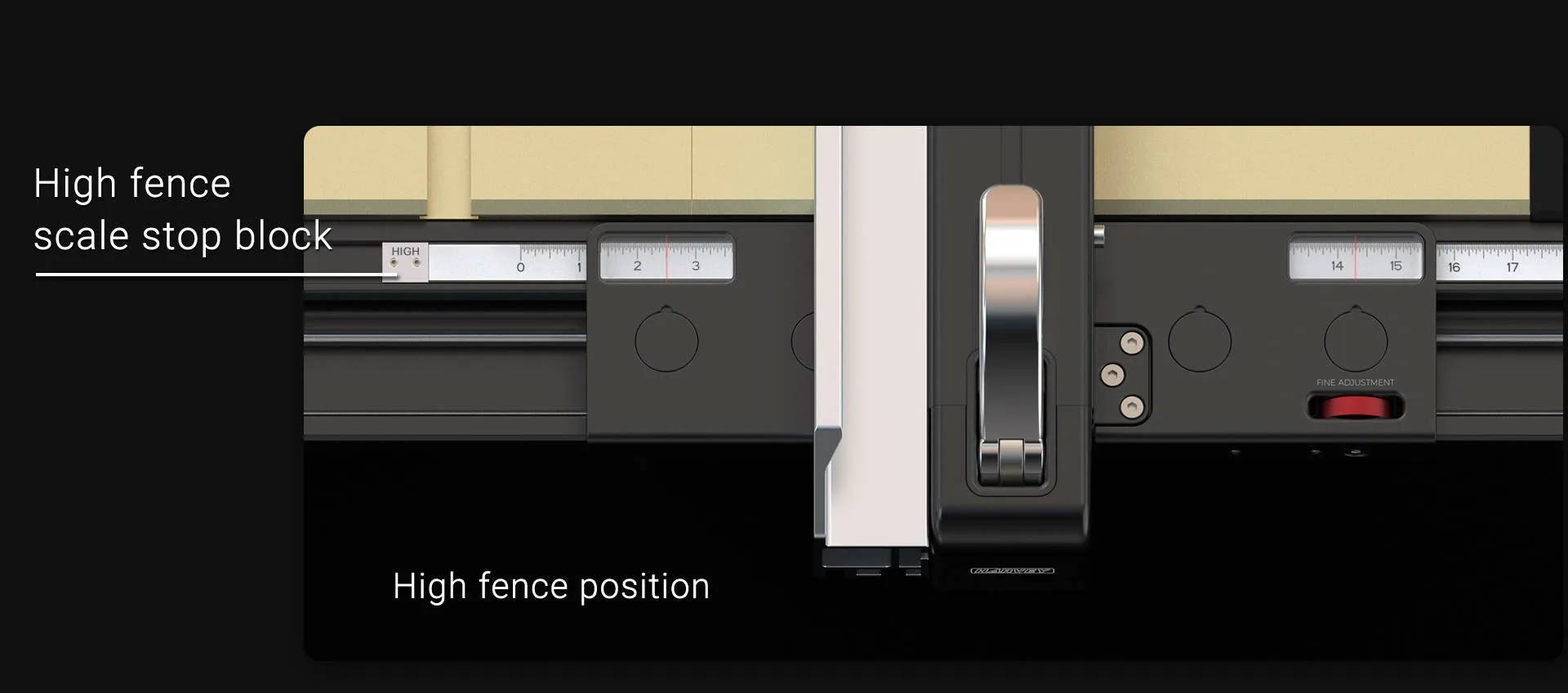

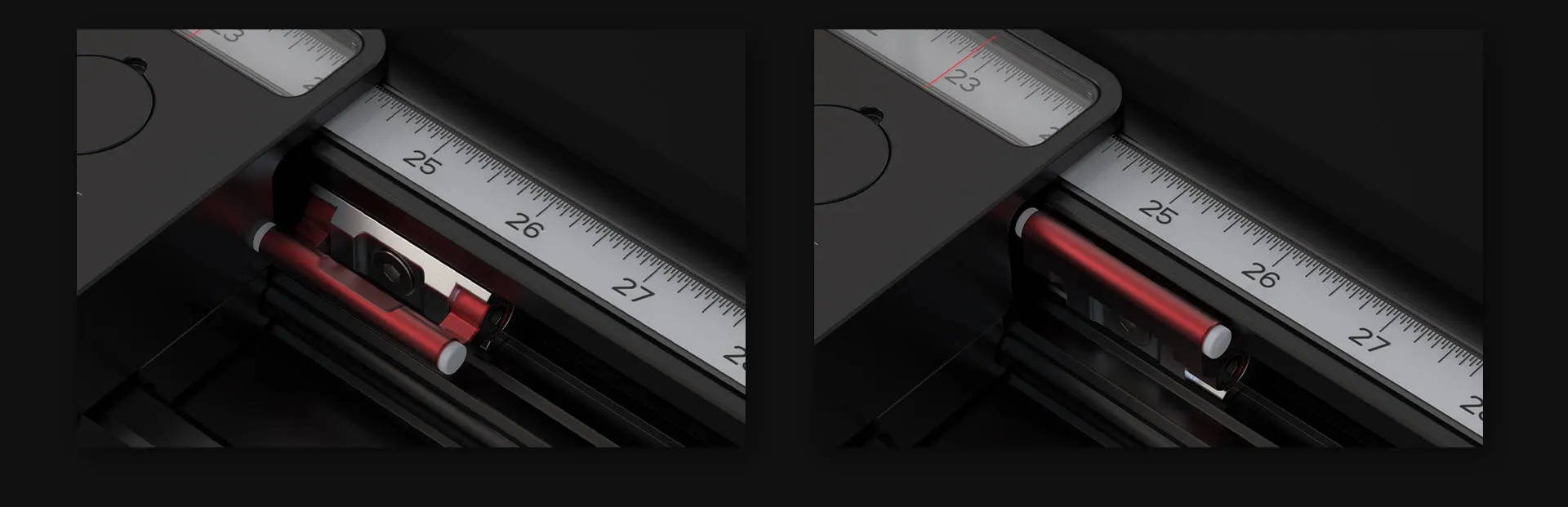

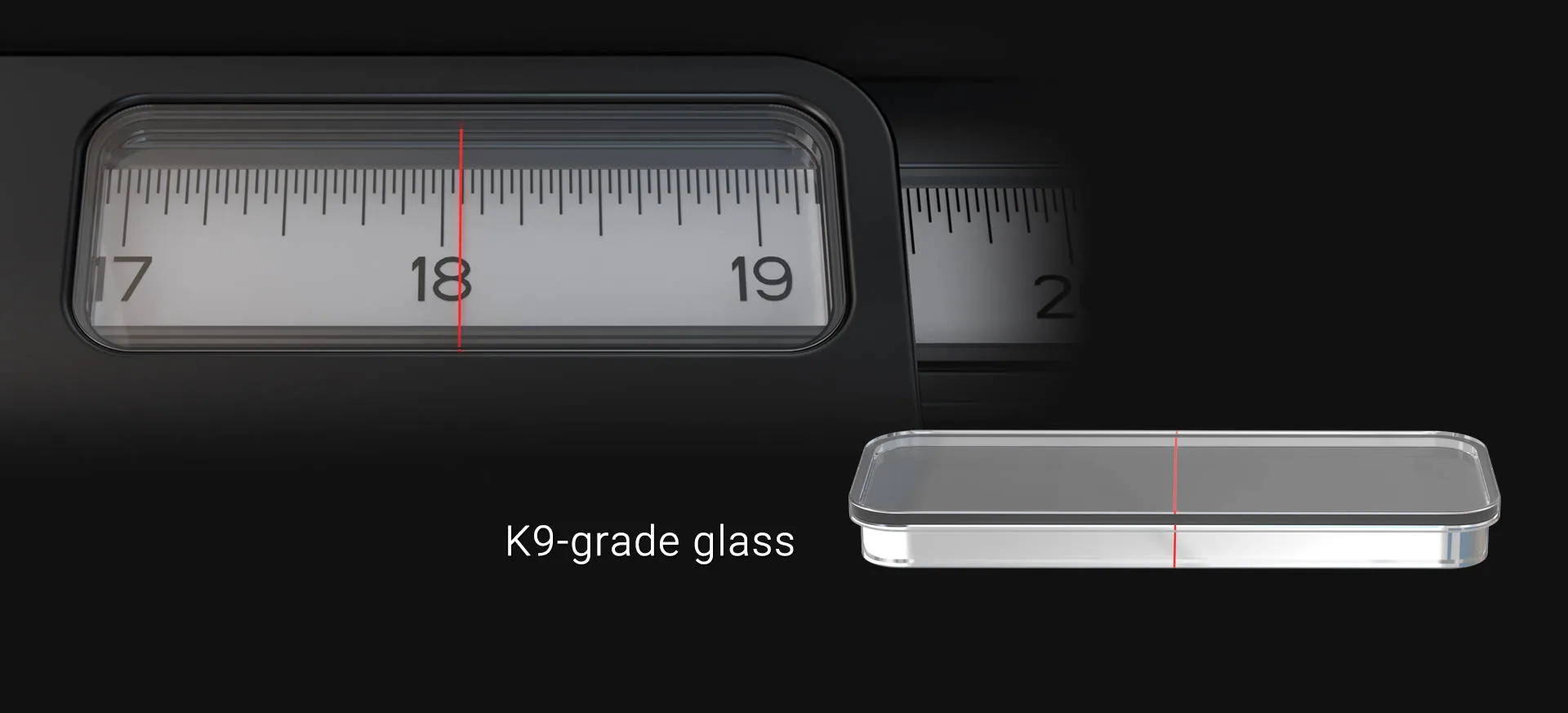

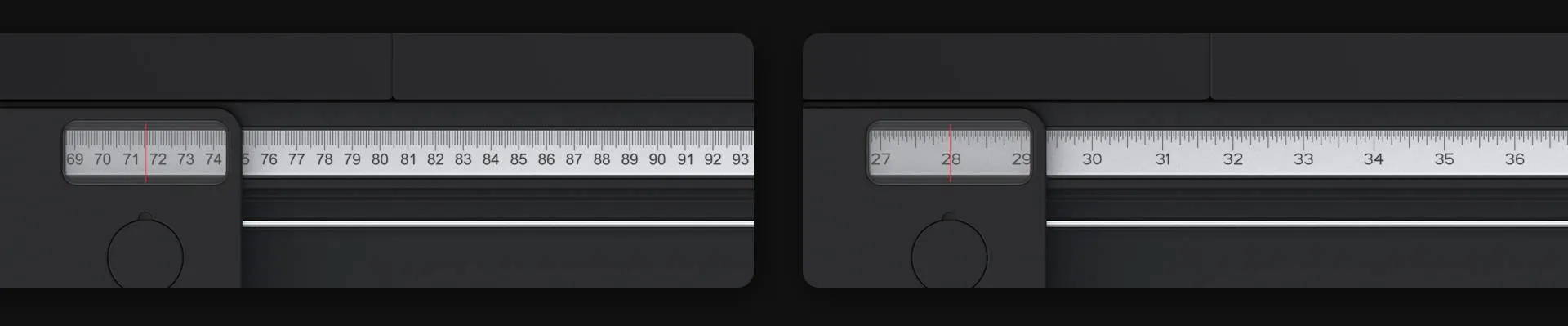

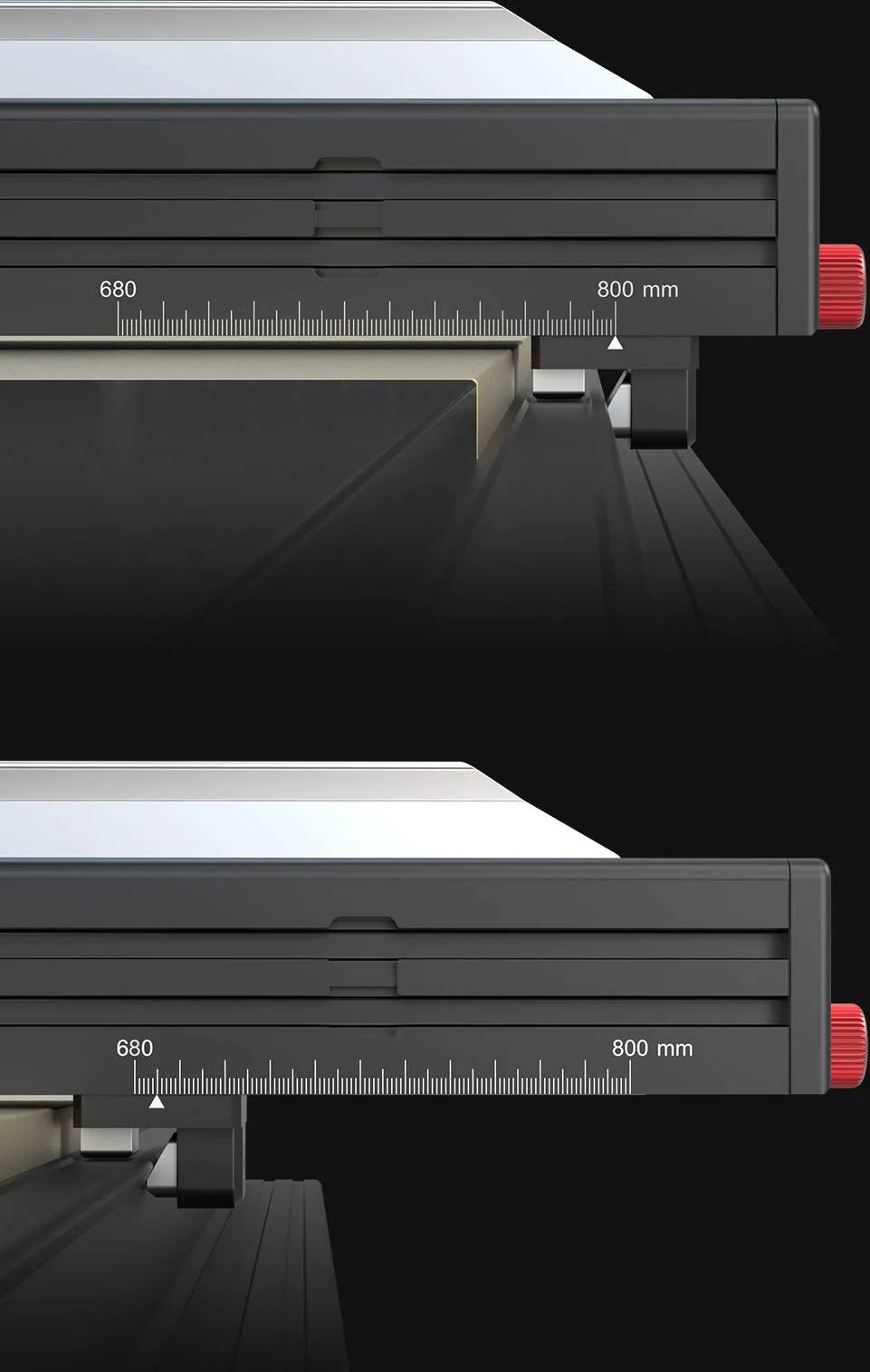

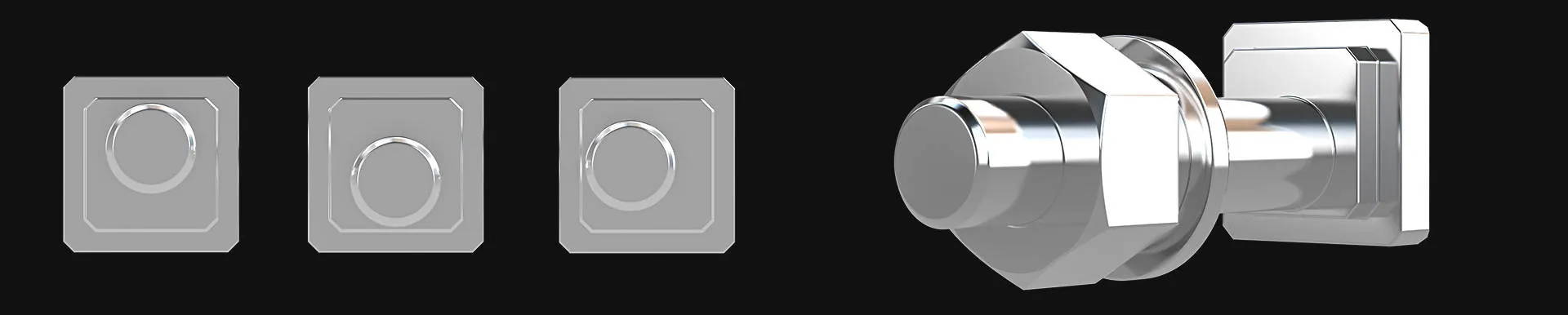

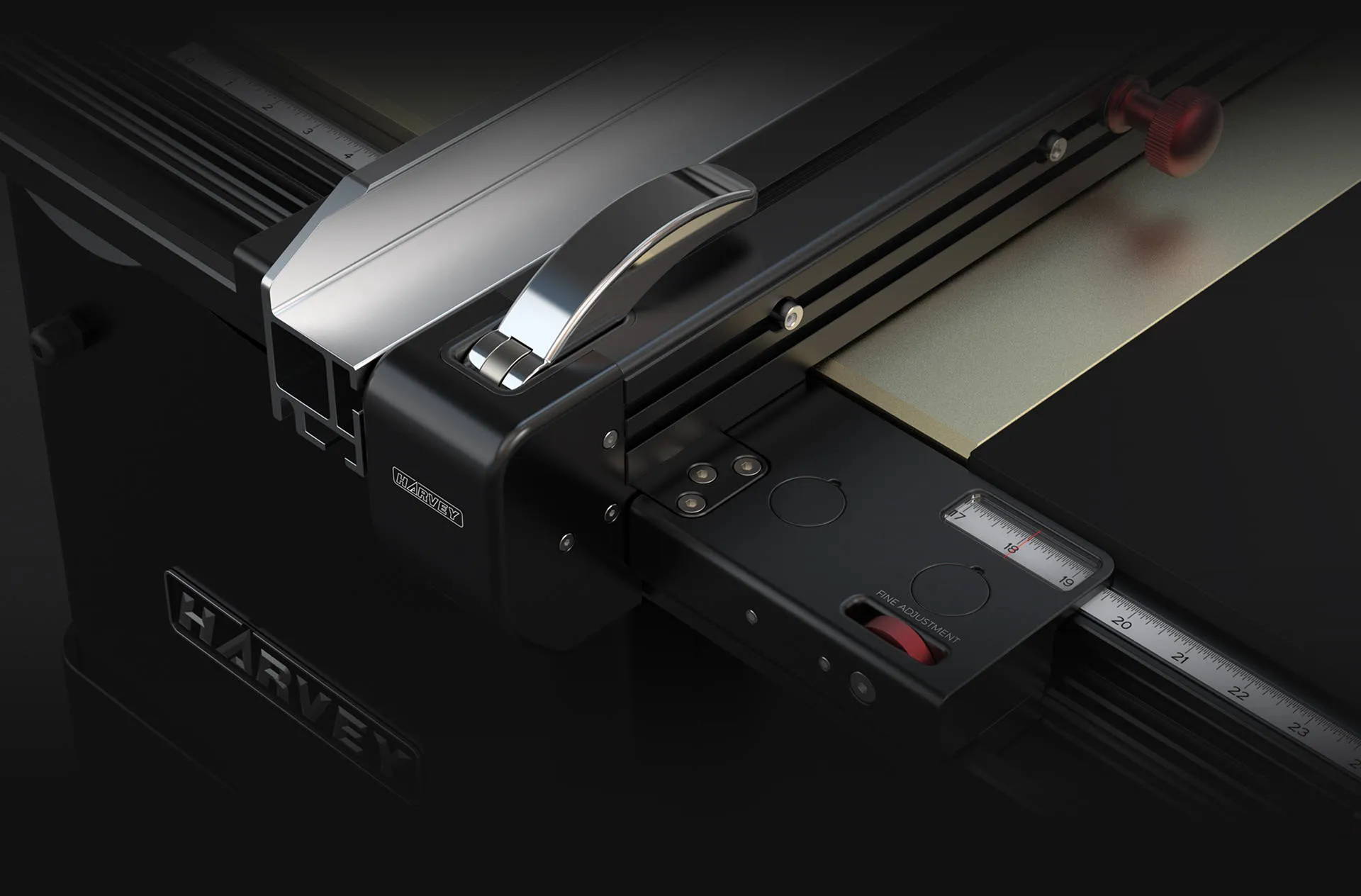

The instructions on the proper alignment of the scale, with regards to the high and low fence positions and sight glasses would also be beneficial. I understand that most experience would workers would already understand this, but as a relative novice, it took longer than I care to admit for me to figure out and get everything properly situated.

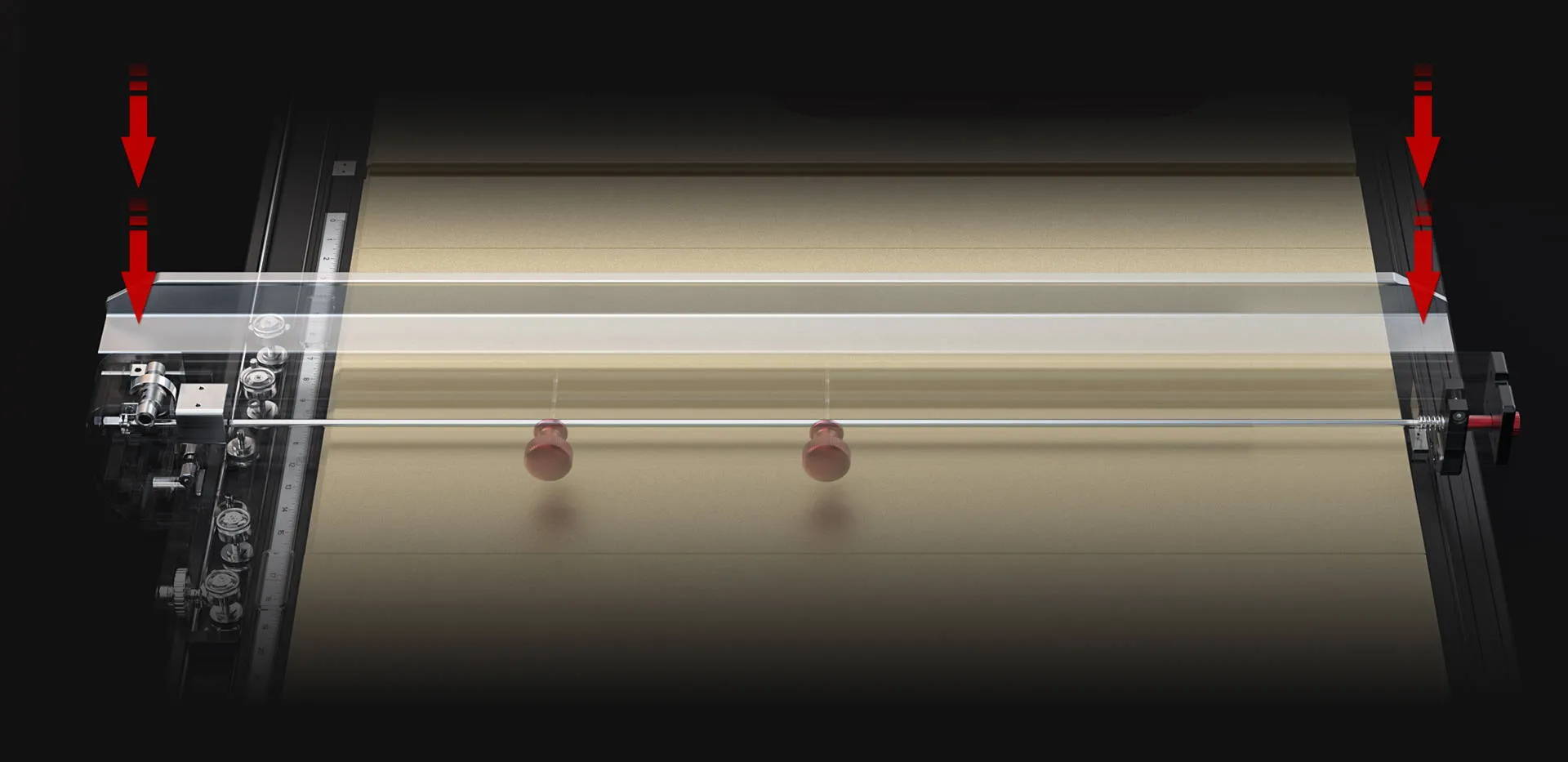

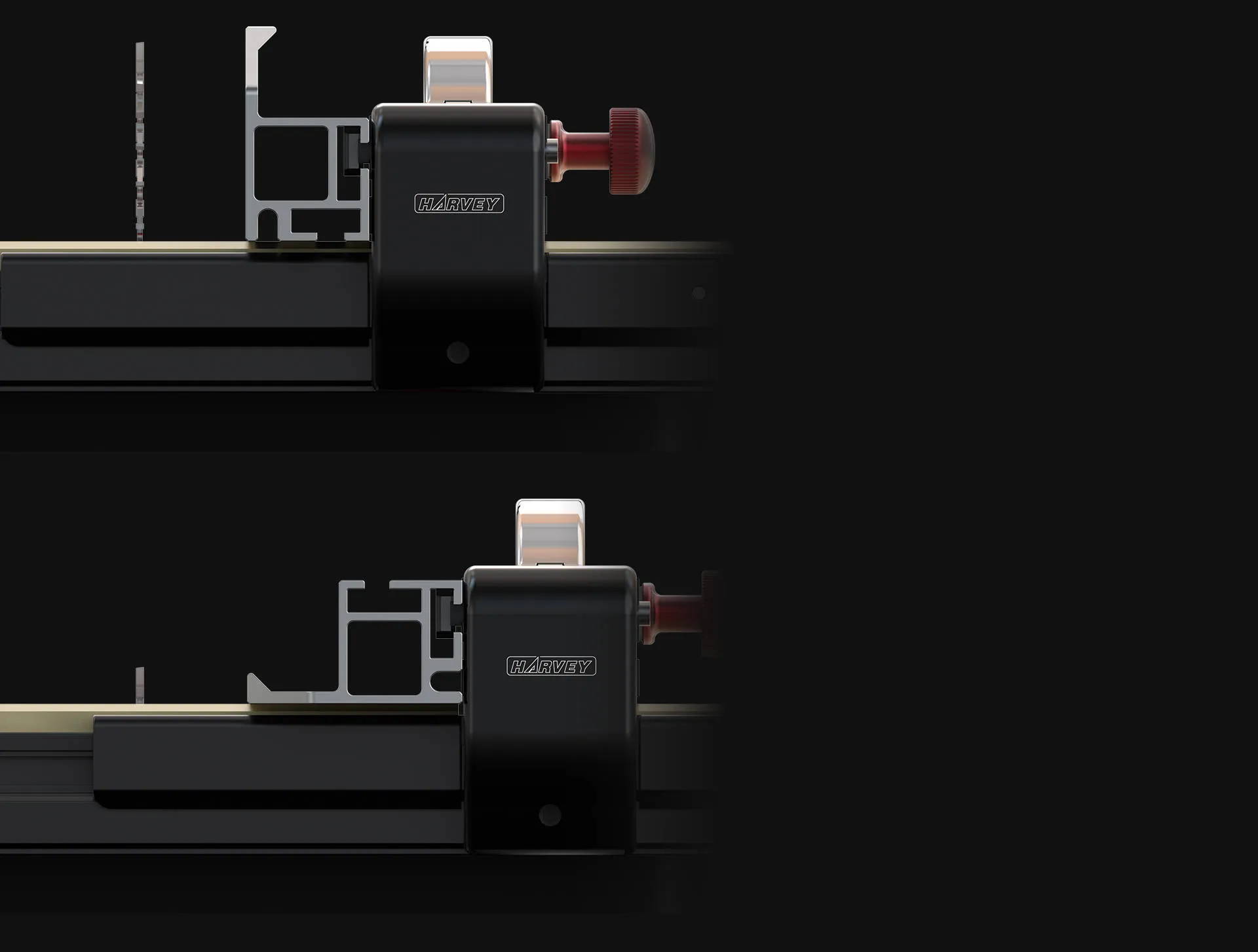

Additionally, there were two of the mounting bolts provided that did not match anything in the parts list. I am working off of memory here, but I believe that they were 30 mm M8, whereas the instructions only indicate 40mm or 55mm inmate hardware. As it turns out, these additional parts belong to the connecting rod assembly, which affixes the tail end of the fence rails. It caused no small amount of consternation during install as I had two different size fasteners and no indication of where they go.

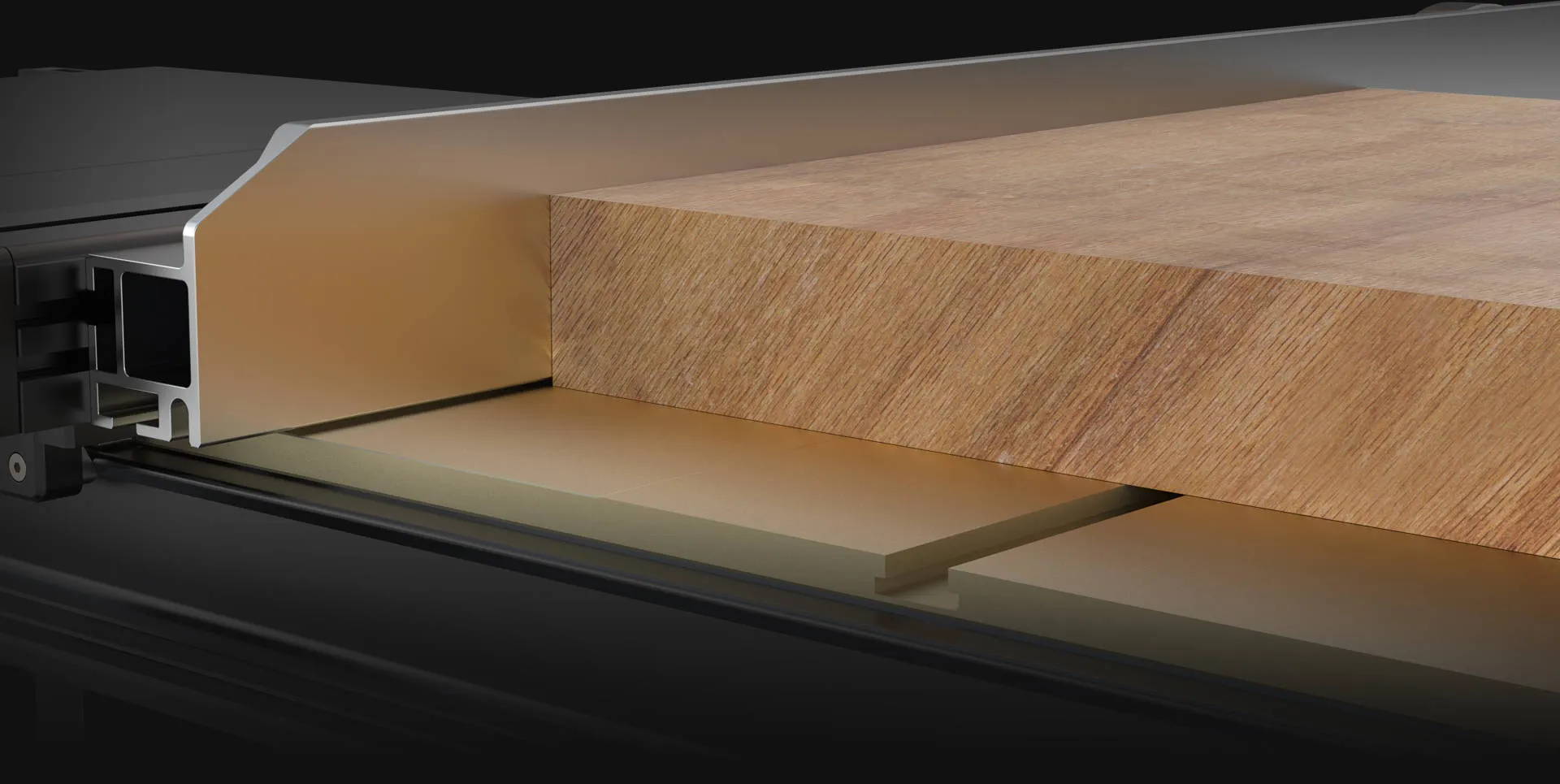

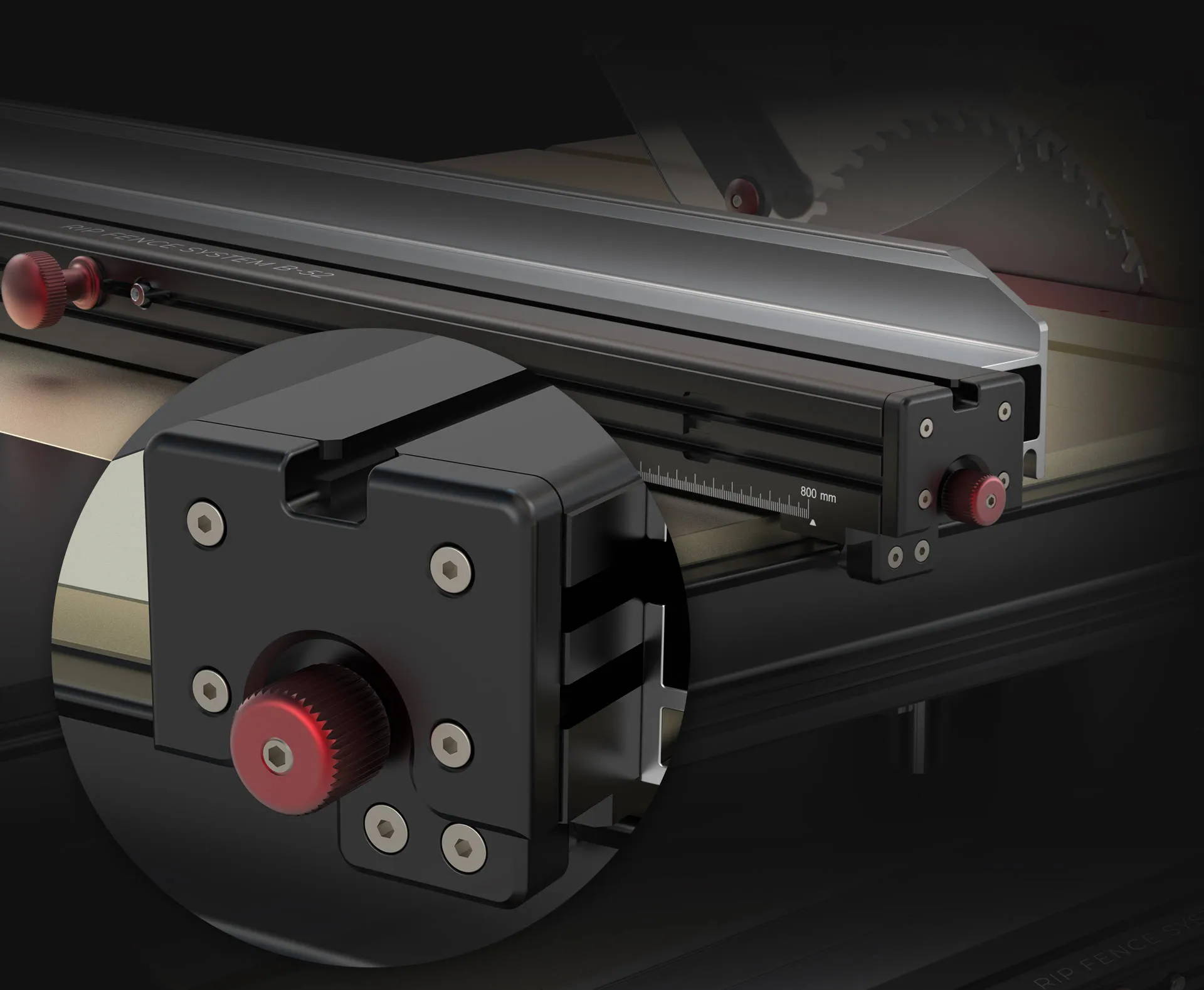

One area which could also use some more clarification is the trailing edge of the fence. Just a simple diagram showing how the bevel on the clamping edge and the Teflon guide block that rides on top of the rear rail a line would be handy. It took more time than I care to admit to figure it out, including having to cut the threaded guide rod sleeve twice in order to get proper fit.

I completely understand the difficulties in writing technical documentation that caters to the lowest common denominator, such as myself, when coming from an engineering perspective. It is also a reasonable assumption that the people that would be investing over $1,000 in a new table saw fence would have the requisite experience and knowledge to improvise. I recognize that I am very much an outlier in both of these fields, and the fact that my saw is over a decade old certainly does not help.

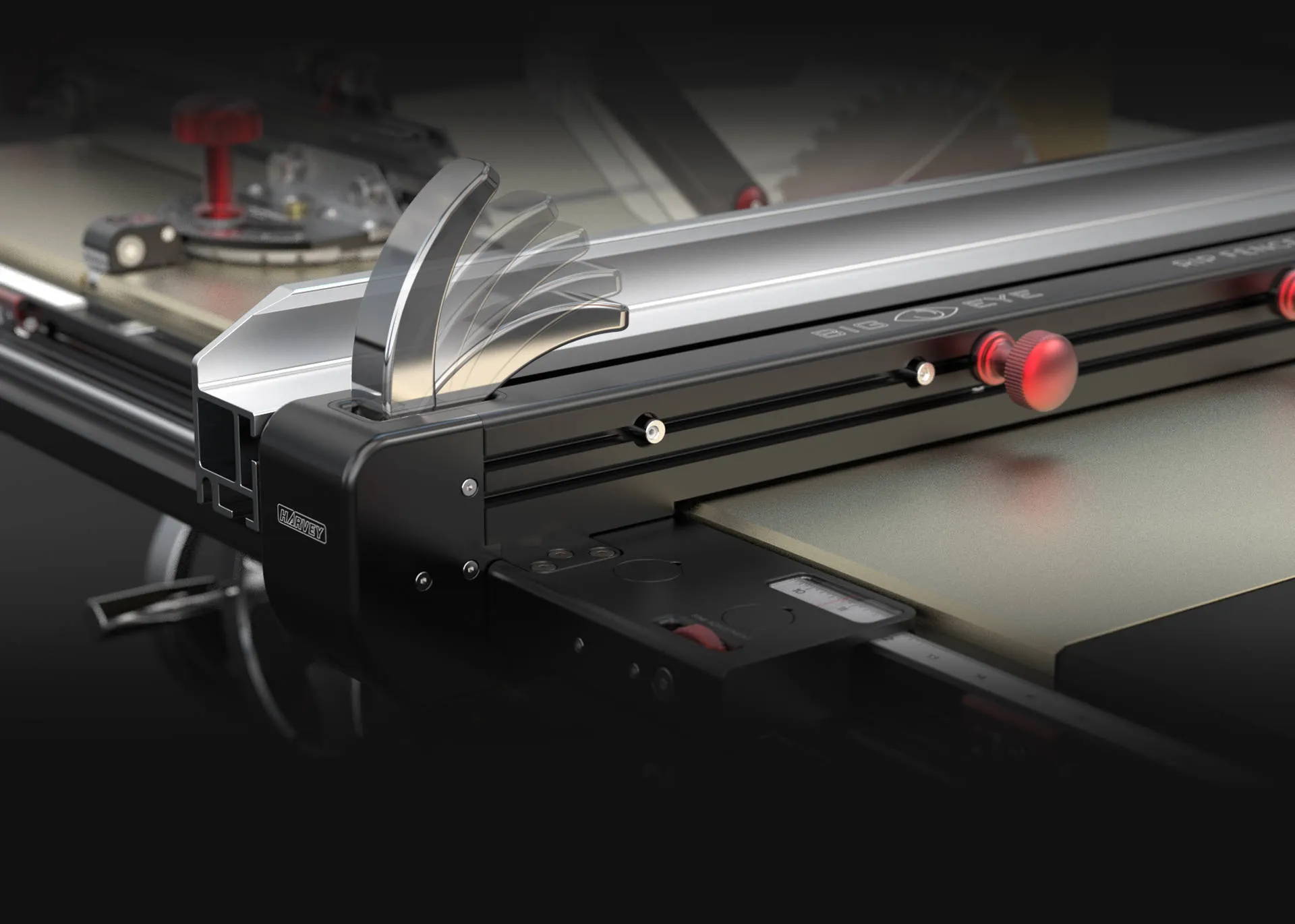

In summary, this product is fantastic. When it locks, it locks Rock solid, to the point where I can shake my entire 700 lb table saw without the fence budging at all. The amount of adjustability built into this fence is incredible. I was able to find tune and tweak everything to get it dialed in exactly perfect. Less than 10 microns of run out on the fence across the entire length of the table. It is such an incredible product, produced and packaged with such evident care. It is truly the top of the line in terms of table saw fences. Unfortunately, I feel that the documentation does not live up to the quality of the product itself.