Brand: Harvey Woodworking

Model: AMBASSADOR C14Pro 3HP 14" Stain-less Bandsaw

Type: Floor-standing woodworking bandsaw

Horsepower: 3HP (2.2kW)

Electric Phase: 1Ph

Voltage: 230V

Current: 12.8A (Full Load)

Frequency: 60Hz

Phase: Single (1Ph)

Receptacle (N. America): NEMA 6-20

Circuit Breaker: 20A with RCD Module

Application: Wood

Automation: Manual Operation

Certification: UL62841, CE, TÜV Rheinland (European/Asian markets)

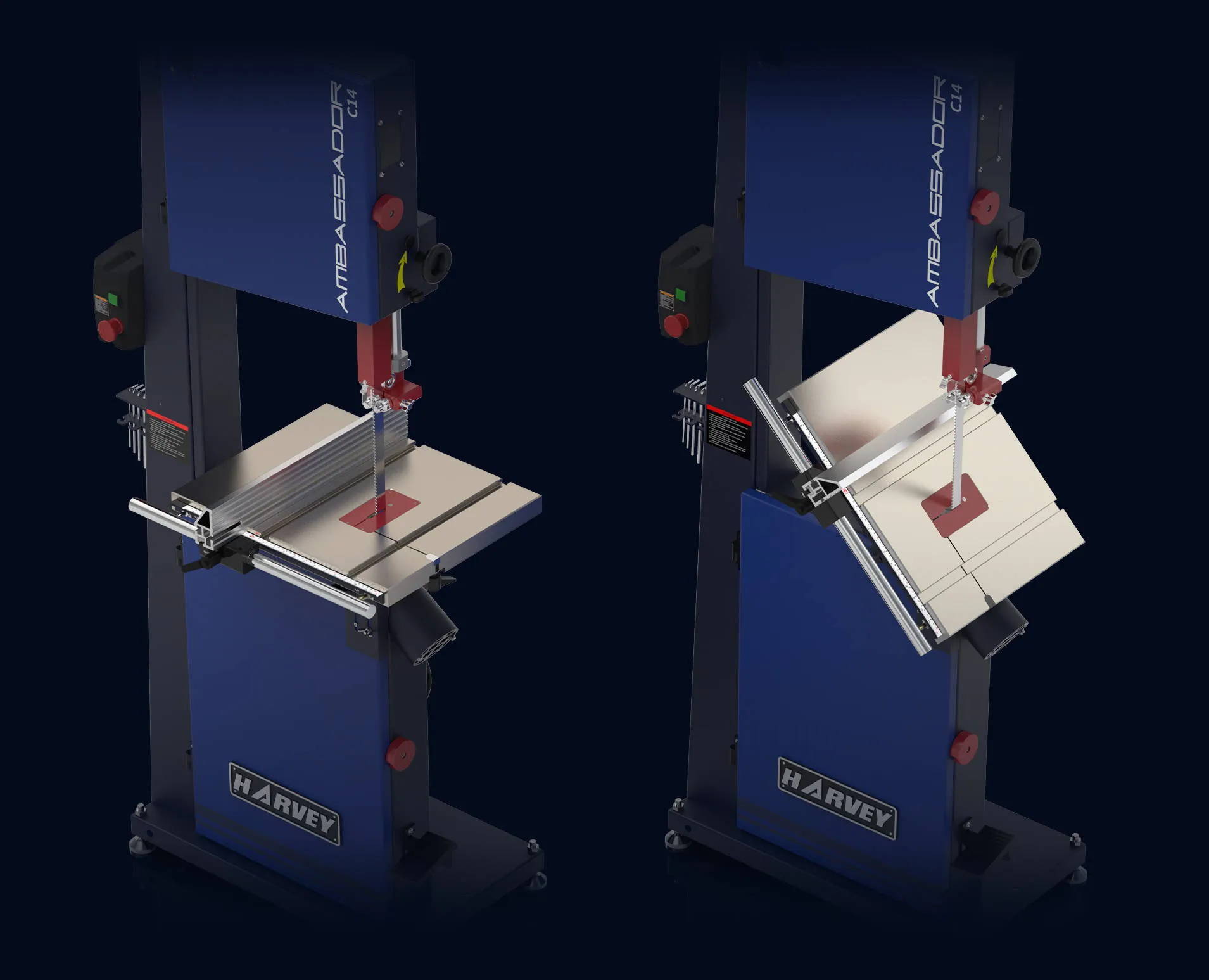

AMBASSADOR C14Pro

3HP 14" Stain-less Bandsaw

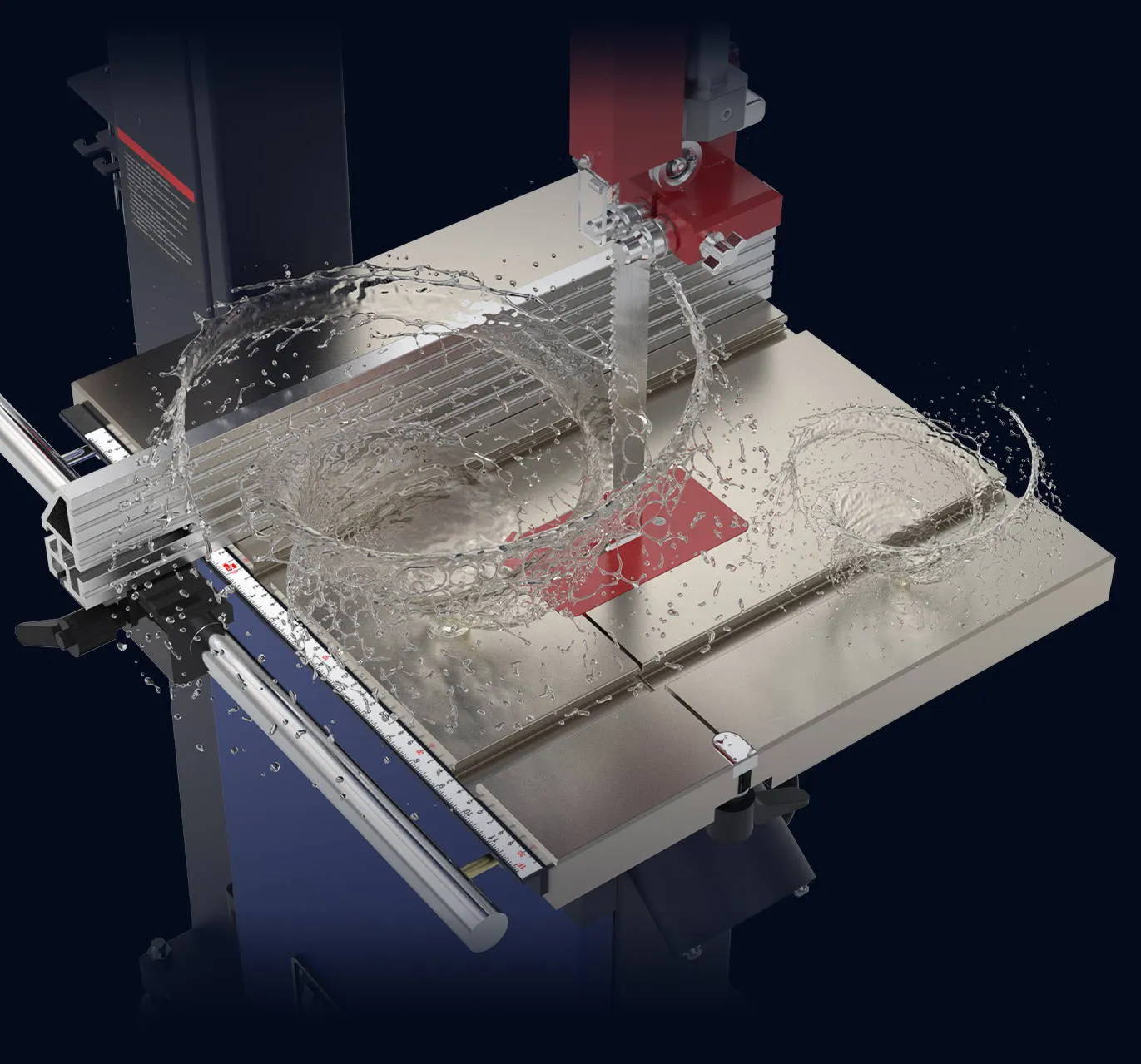

For many woodworkers, rust on bandsaws has long been a source of frustration. About ten years ago, Harvey began addressing this challenge by incorporating the TIN PVD Coating technology into products, reducing wear and rust on table saw surfaces.

However, Harvey is always striving for perfection. Five years ago, we started exploring the nickel plating technology. After countless tests on the process and formulation, we have successfully implemented optimal nickel plating technology on the tabletop, the cast iron flywheel and the Rack and Pinion Table Tilting System within the bandsaws, ensuring a literally rust-free experience for users by completely eliminating issues of wear and rust.

This superior nickel plating solution adopts the autocatalytic plating process, combining with a mid-phosphorus chemical nickel formula, significantly enhances wear resistance and rust prevention capabilities, resulting in a smoother and more lustrous finish.

Furthermore, the nickel-plated table surfaces achieved an impressive hardness of 500HV - 700HV, considerably improving their wear resistance. Extensive friction tests using wooden blocks consistently demonstrated that the nickel layer effectively protected the table surface.

We conducted a series of high-temperature and strong acid corrosion tests to evaluate the longevity of the nickel-plated surfaces. The results indicated that, under normal usage conditions, the nickel-plated surfaces could maintain their rust prevention performance for years. Notably, even in highly humid working environments, they exhibited exceptional rust prevention capabilities.

We are confident that the AMBASSADOR C14Pro Stain-less Bandsaw represents the ultimate solution to the rust problem in bandsaws. Guided by our steadfast philosophy that "Good Enough is Not Enough," this bandsaw exemplifies our unwavering dedication to innovation and precision.

What’s more, the AMBASSADOR C14Pro Stain-less Band saw features a powerful 3HP motor, 14" resaw capacity, super solid steel frame (over 350 Ibs in weight), heavy-duty cast iron flywheels, uniquely designed Tool-less blade guides, the newly developed COMPASS RG-2 Roller Guide for your safe and enjoyable cutting; foot brake with micro switch, magnetic on/off switch, rack and pinion table tilting system, quick- release tension as well as Harvey uncompromising fine craftsmanship.

For woodworkers seeking a bandsaw that combines traditional reliability with innovative features, the AMBASSADOR C14Pro is the ultimate choice. Experience the next level of industrial-grade woodworking machinery with Harvey Industries.

Features and Benefits

* Nickel-Plated Worktable For Superior Rust and Wear Resistance

* Nickel-Plated Cast Iron Rack and Pinion Table Tilting System

*Dynamically Balanced Cast Iron Flywheels with Nickel-Plating

*Powerful 3HP TEFC Single Phase Motor (220V)

*Extraordinary 14" Resaw Capacity

*Unique Tool-Less Upper and Lower Blade Guides

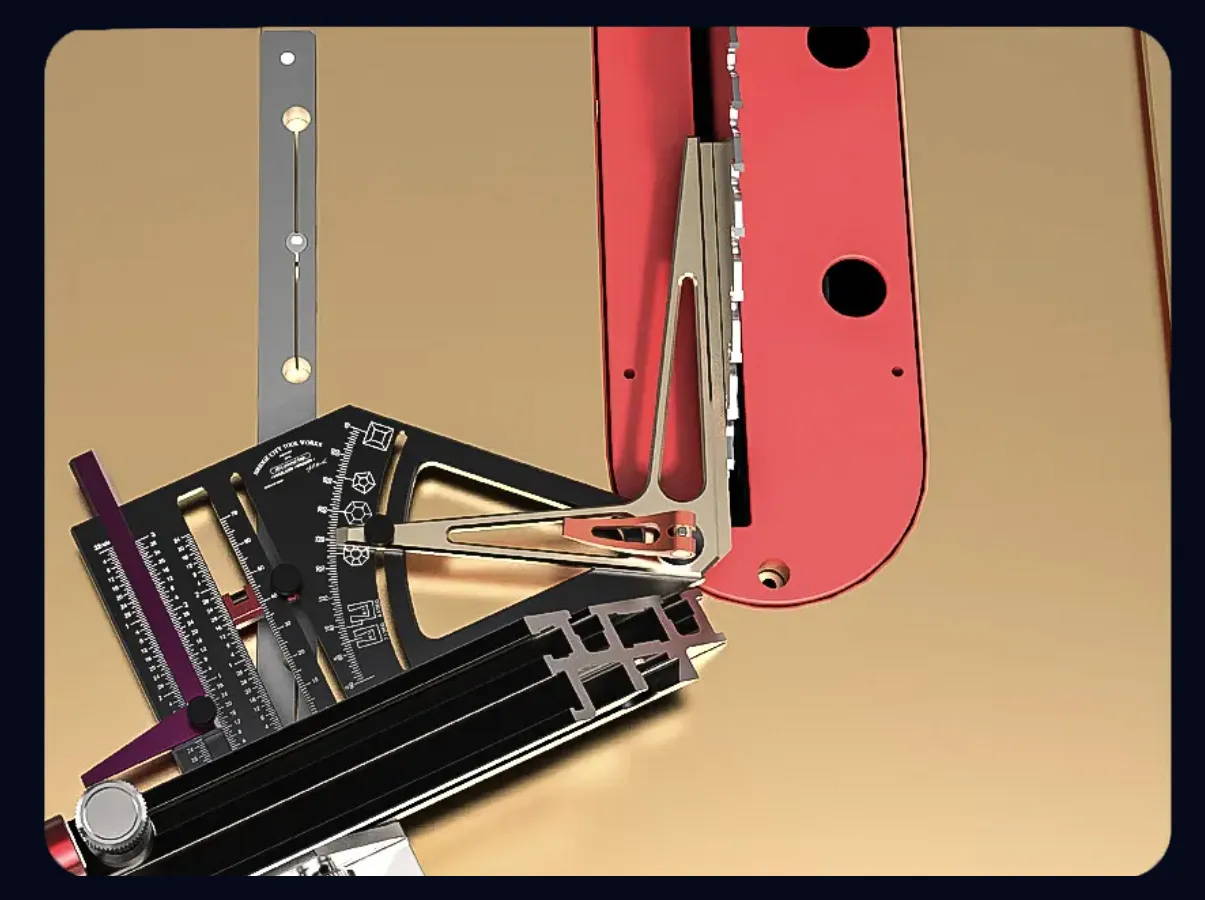

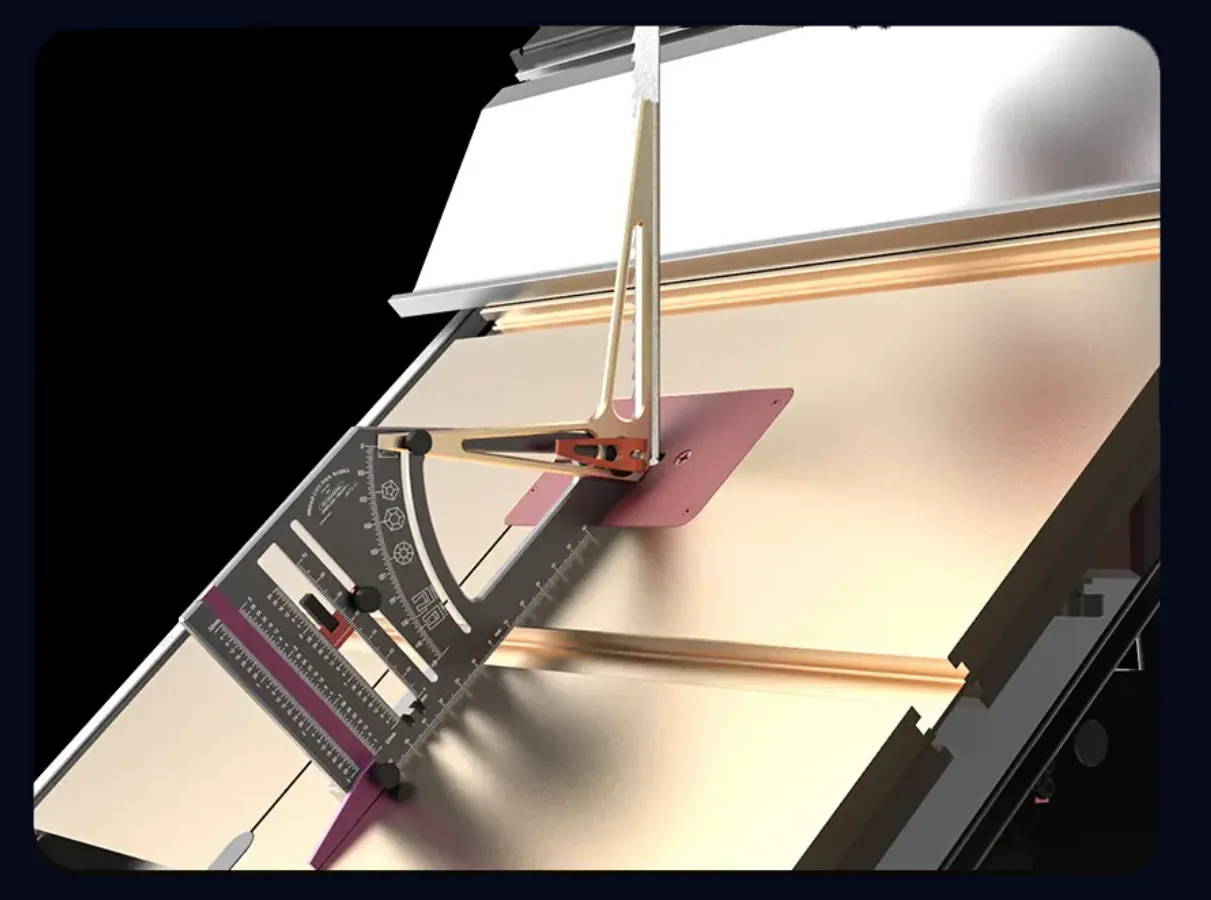

*COMPASS RG-2 Roller Guide

*Foot Brake with Micro Switch

*Quick Release Tensioning Levers

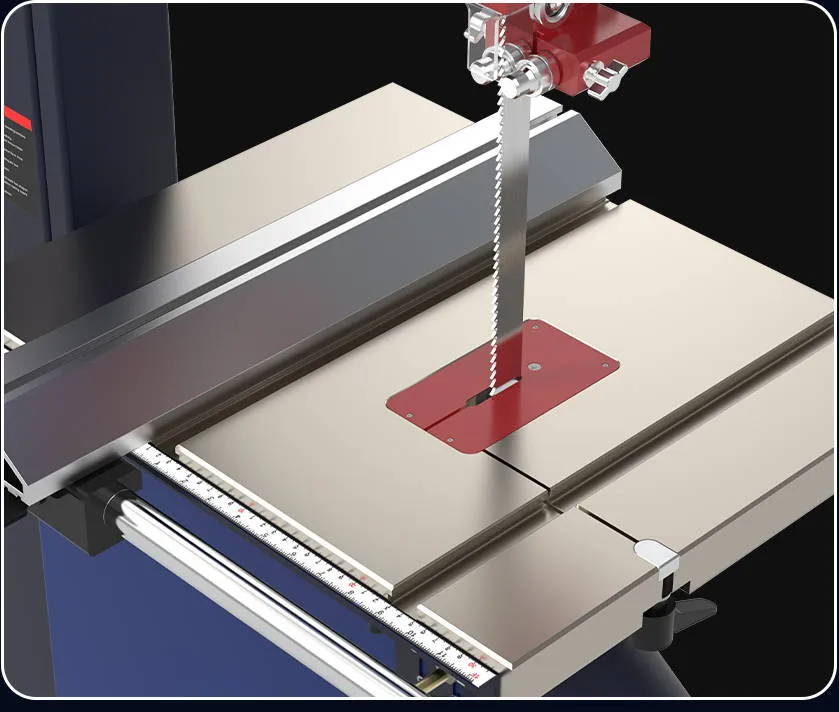

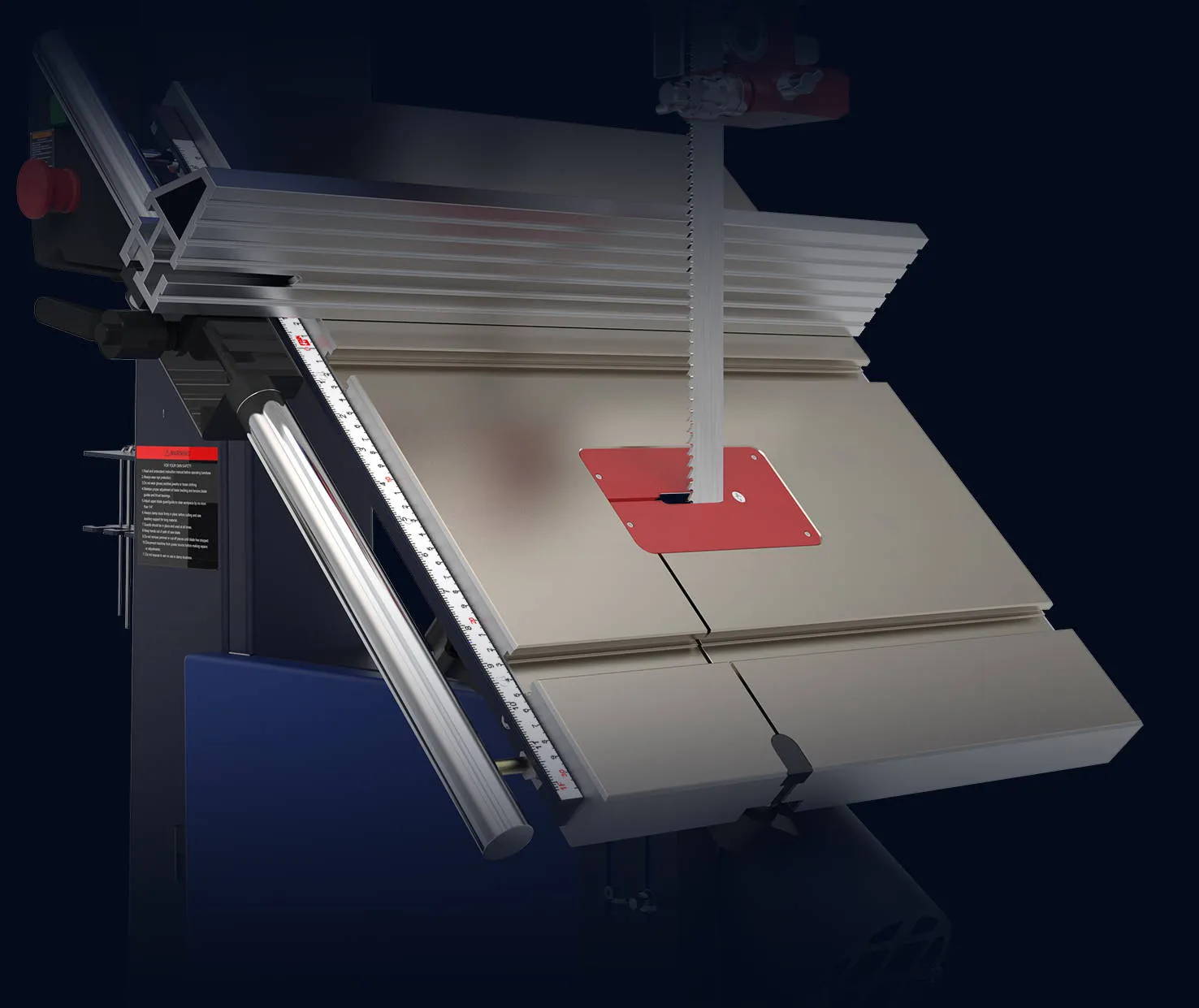

Nickel-plated worktable

The worktable undergoes a chemical nickel-plating process that bonds the nickel layer thickly to the base material, reaching an impressive hardness range of 500 HV to 700 HV, significantly enhancing its durability and resistance to corrosion and wear. Extensive friction tests using wooden blocks consistently demonstrated that the nickel layer can effectively protected the table surface.

Additionally, we performed a series of tests involving high temperatures and strong acids to determine the longevity of the nickel-plated surfaces. The results showed that, under normal conditions, the nickel-plated surfaces could retain their rust-preventive properties for many years. Impressively, they also exhibited excellent rust prevention in highly humid work environments.

A substantial 19-3/4" x 15-3/4" cast iron table offers a smooth surface for precise work.

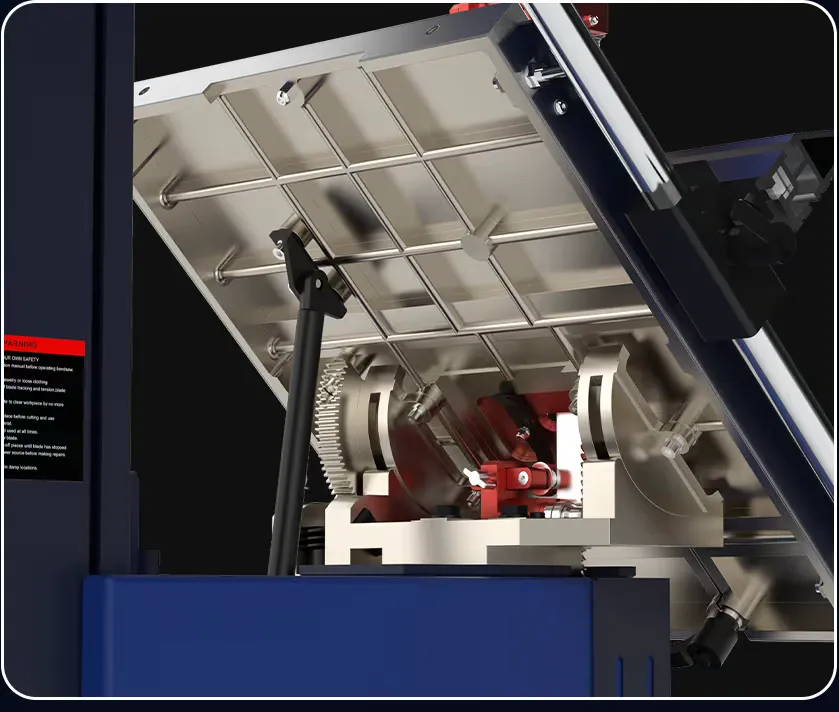

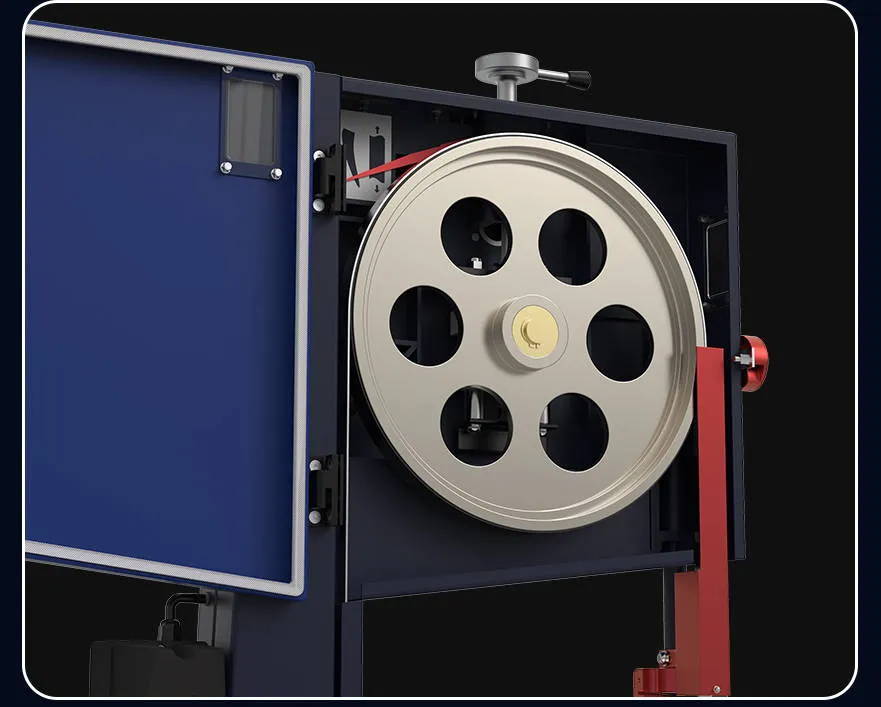

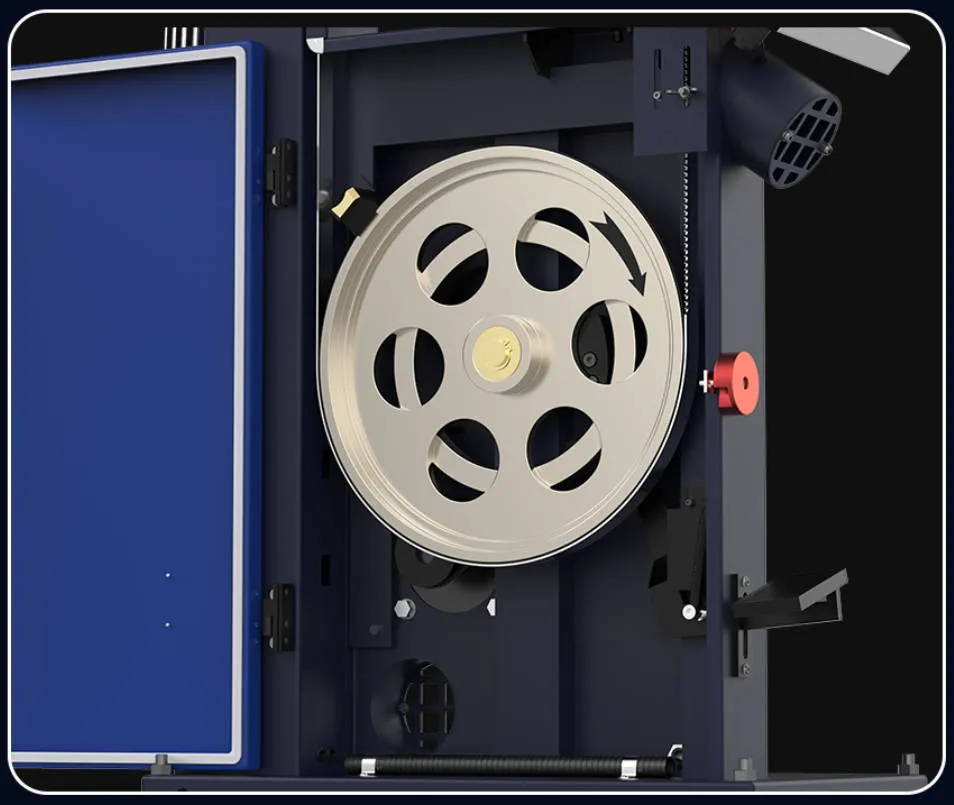

Heavy Duty Cast Iron Flywheels

with Nickel-plating and Reinforced Structural Steel Frame

The nickel-plated Flywheels offer superior resistance to rust and wear, significantly extending their service life.

we performed a series of tests involving high temperatures and strong acids to determine the longevity of the nickel-plated surfaces. The results showed that, under normal conditions, the nickel-plated surfaces could retain their rust-preventive properties for many years. Impressively, they also exhibited excellent rust prevention in highly humid work environments. This ensures rust resistance and longevity, making the flywheels maintenance-free for rust prevention.

Dynamically balanced cast iron flywheels ensure smooth operation, minimal noise, and superior momentum for consistent cutting.

The reinforced solid steel frame provides remarkable rigidity and stability, enhancing durability and performance under the most demanding conditions.

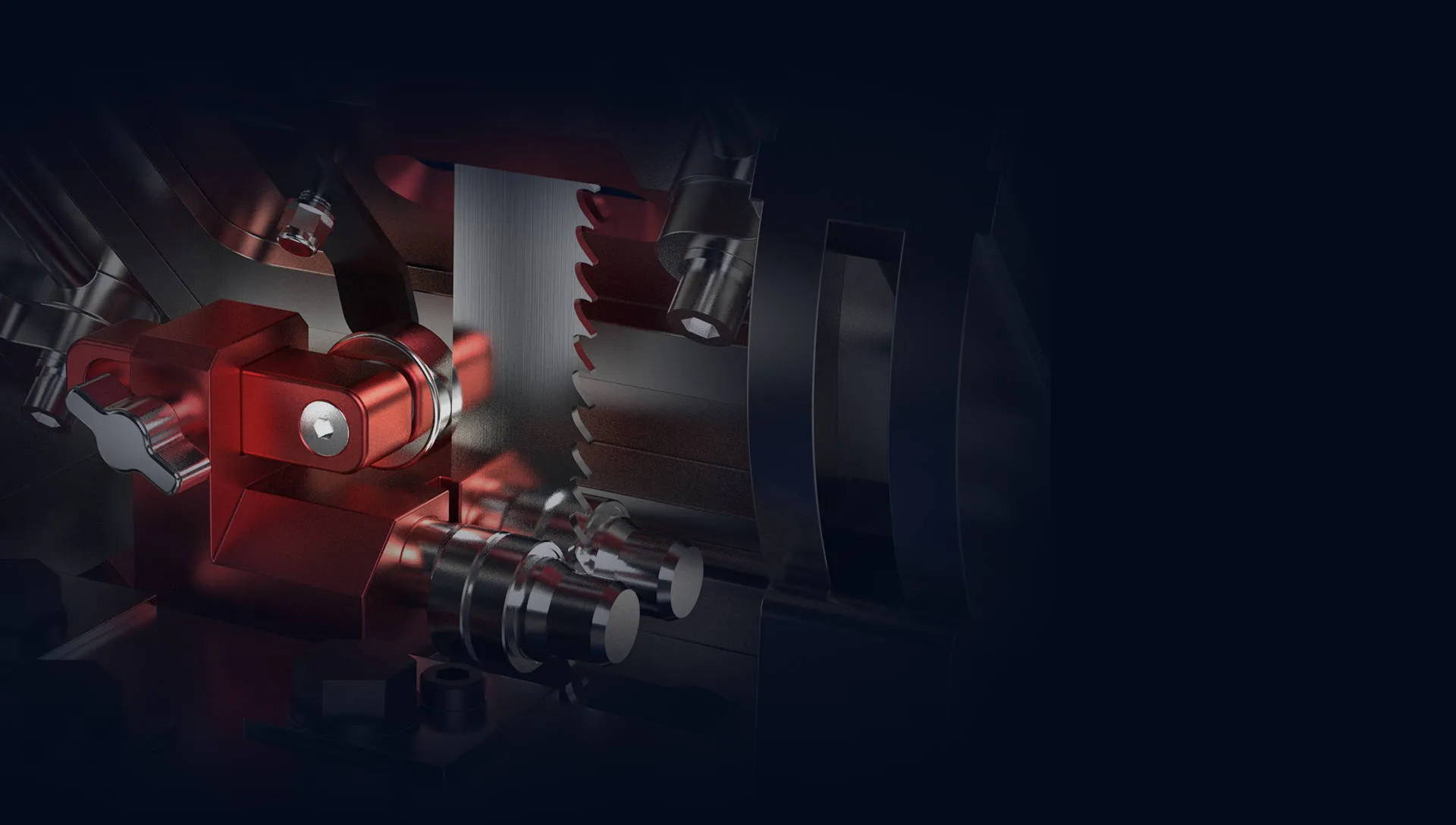

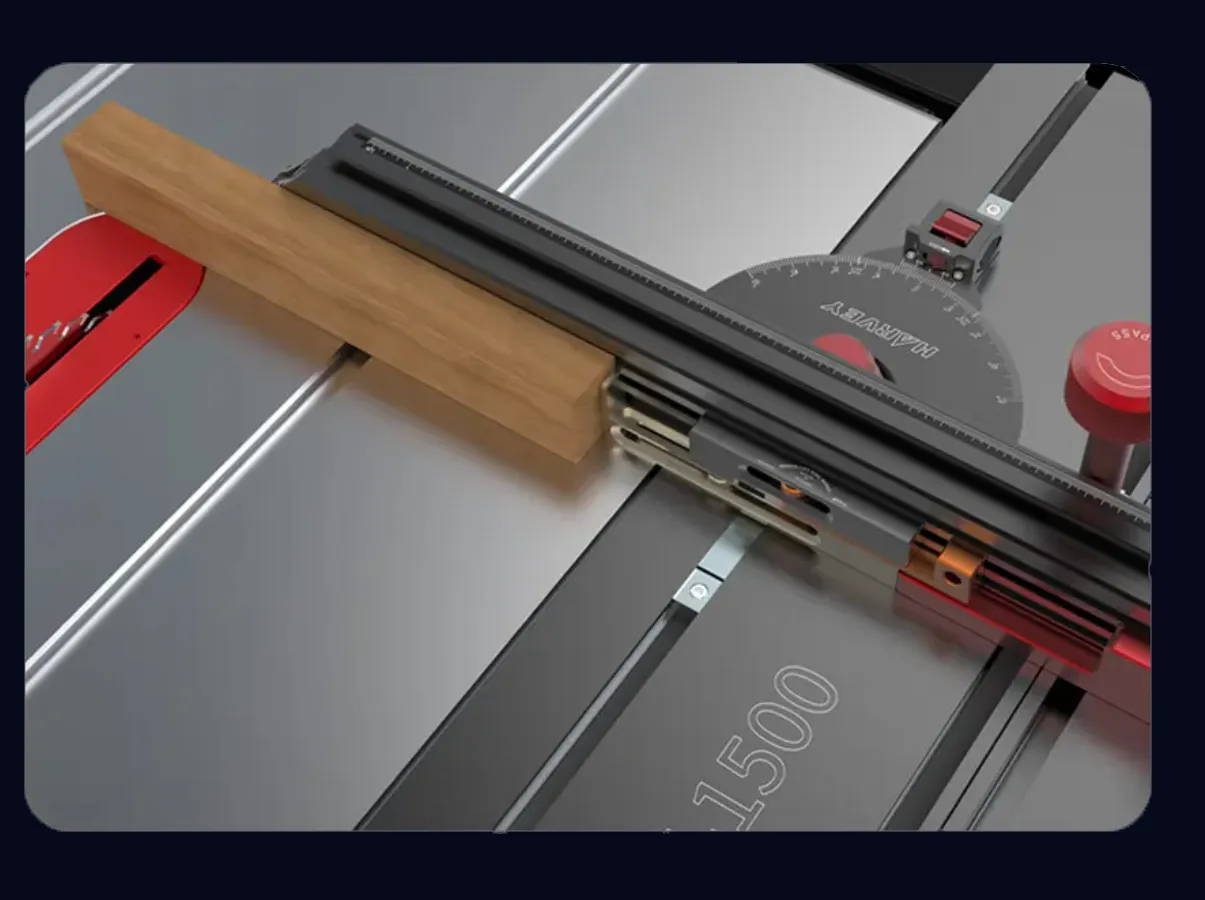

Nickel-plated Cast Iron Rack

and Pinion Table Tilting System

The nickel plating of the entire Cast Iron Rack and Pinion Table Tilting System offers enhanced resistance to corrosion and wear, making the C14Pro virtually maintenance-free for rust prevention.

We carried out a series of high-temperature and strong acid corrosion tests to assess the durability of the nickel-plated components. The findings revealed that, under typical usage conditions, the nickel-plated surfaces could sustain their rust prevention performance for years. Remarkably, even in extremely humid working environments, they demonstrated outstanding rust prevention capabilities.

Precisely tilt the worktable from 45 degrees to -15 degrees using a Rack and Pinion Table Tilting System. Gas pistons assist in micro-adjustments, making the process smooth and straightforward.

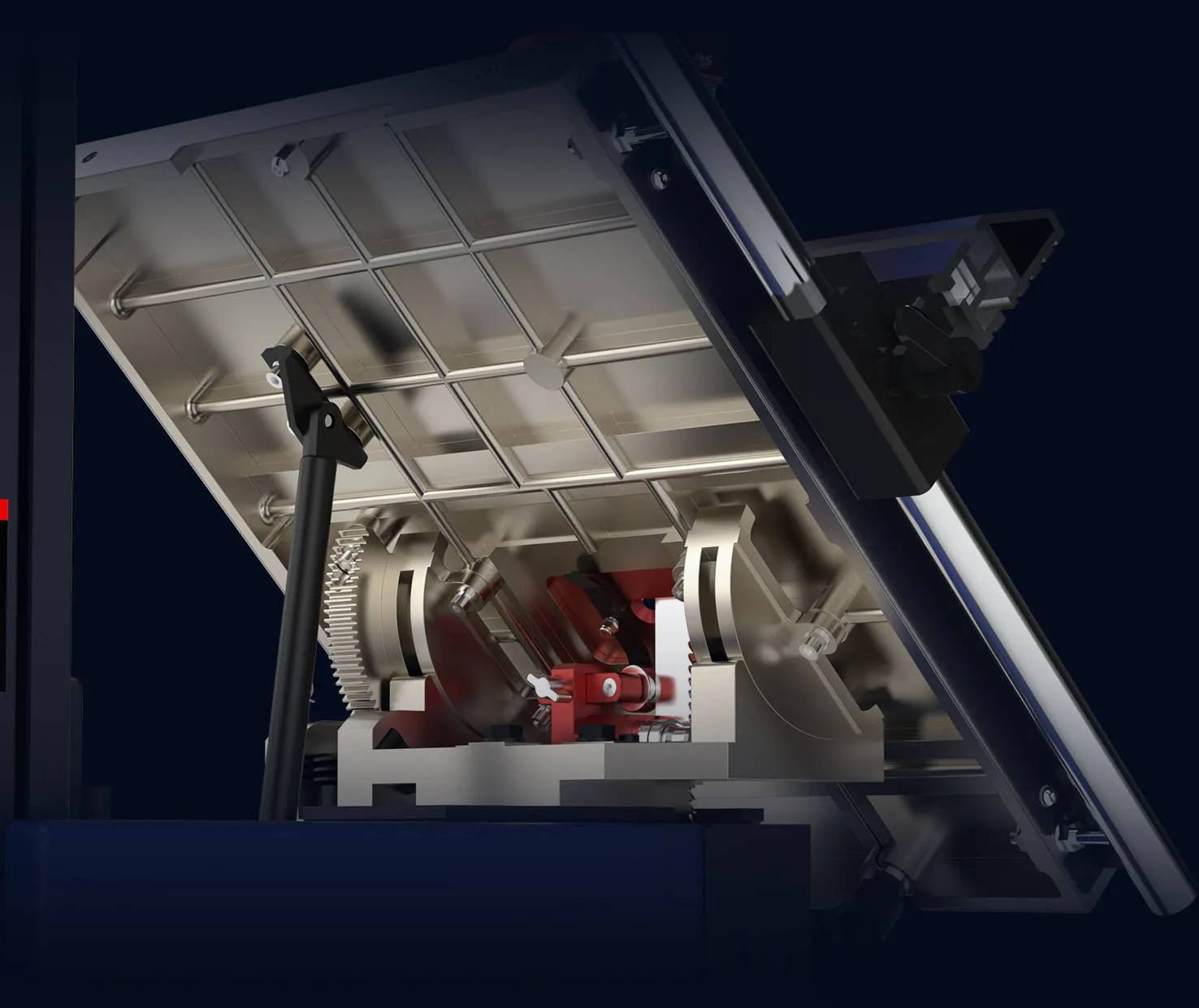

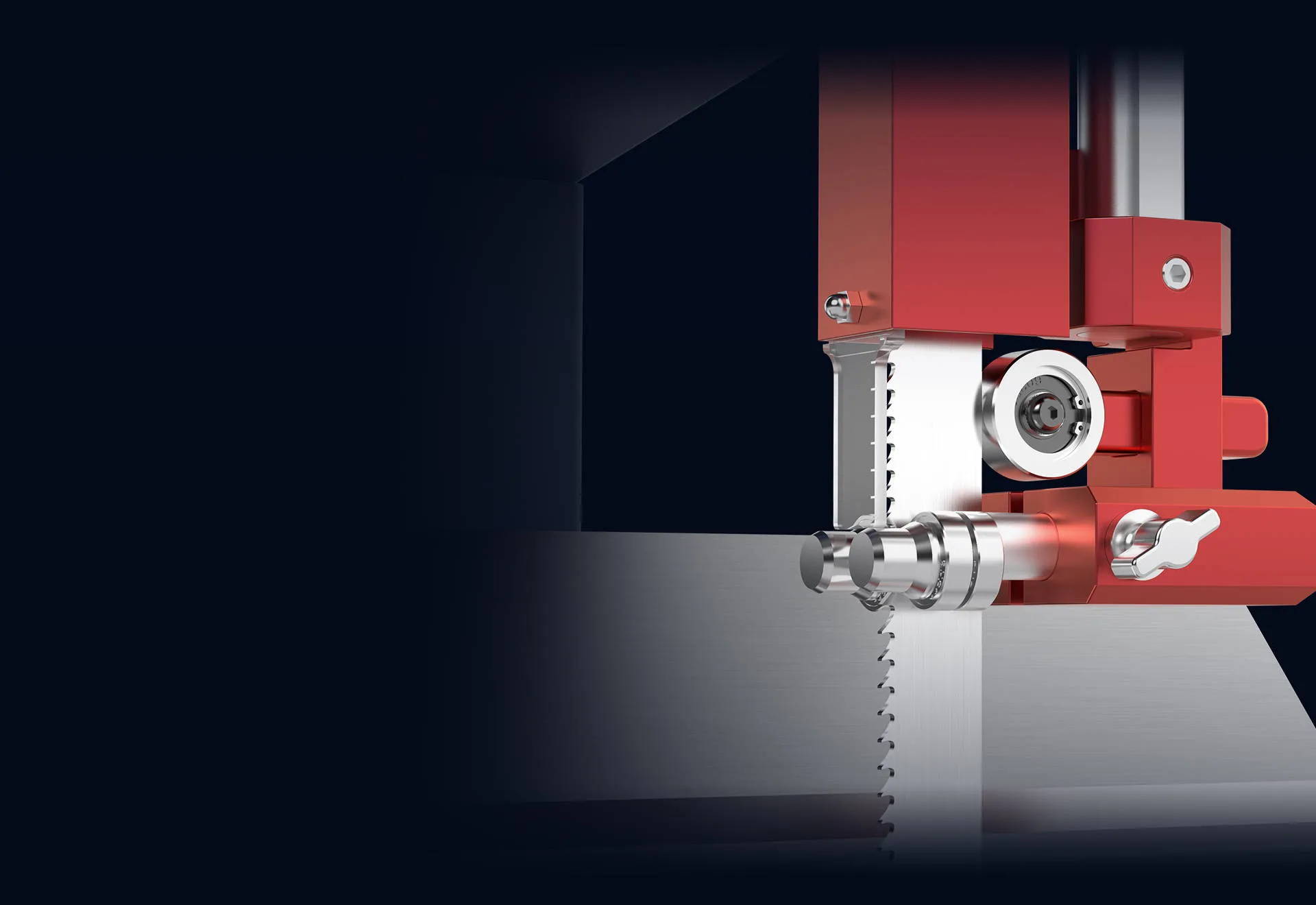

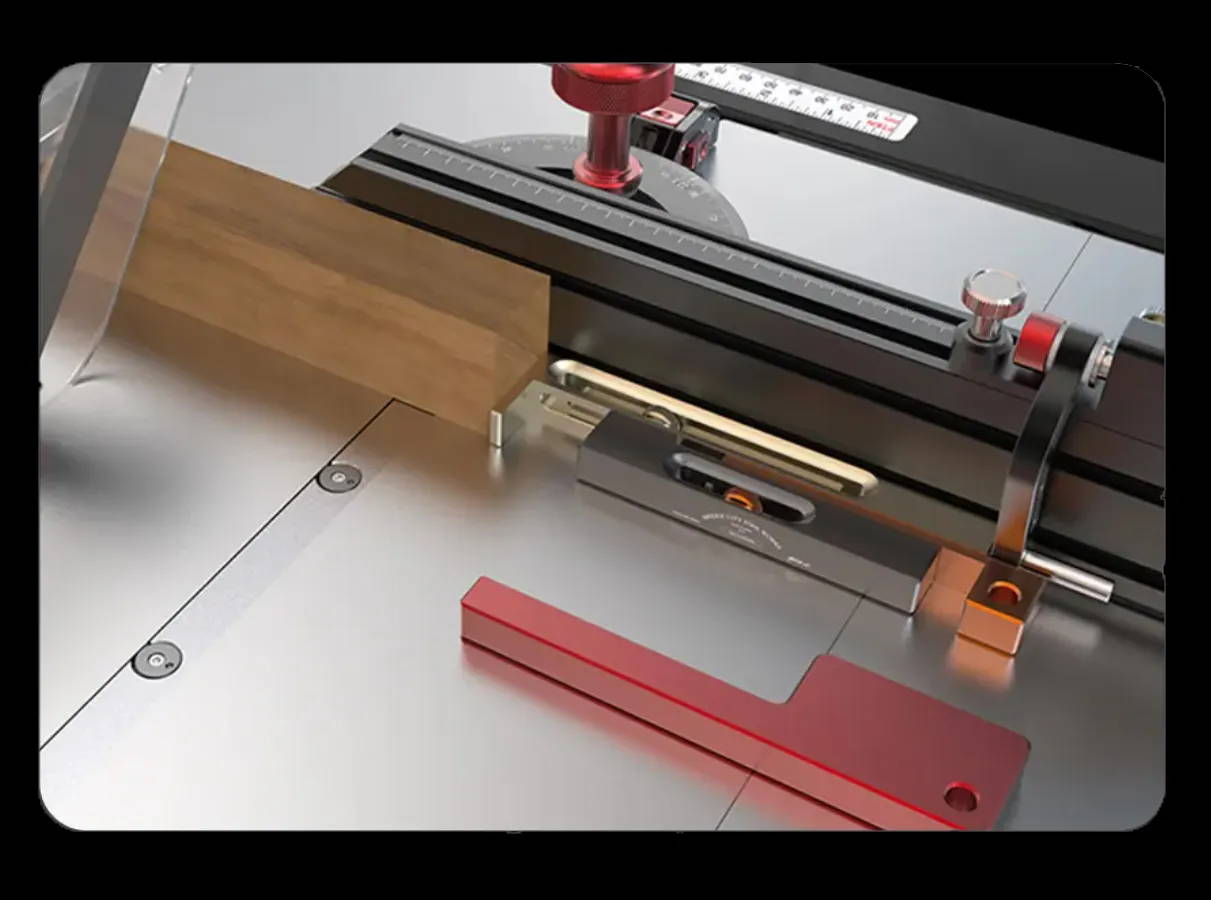

Ball Bearing Blade Guides

feature Tool-less Adjustment

The newly designed ball bearing blade guide has a ball bearing on each side of the blade and the back of the unit which ensures the minimum blade movement.

The tool-less adjustment and lock knobs are thoughtfully designed to provide easy access and use.

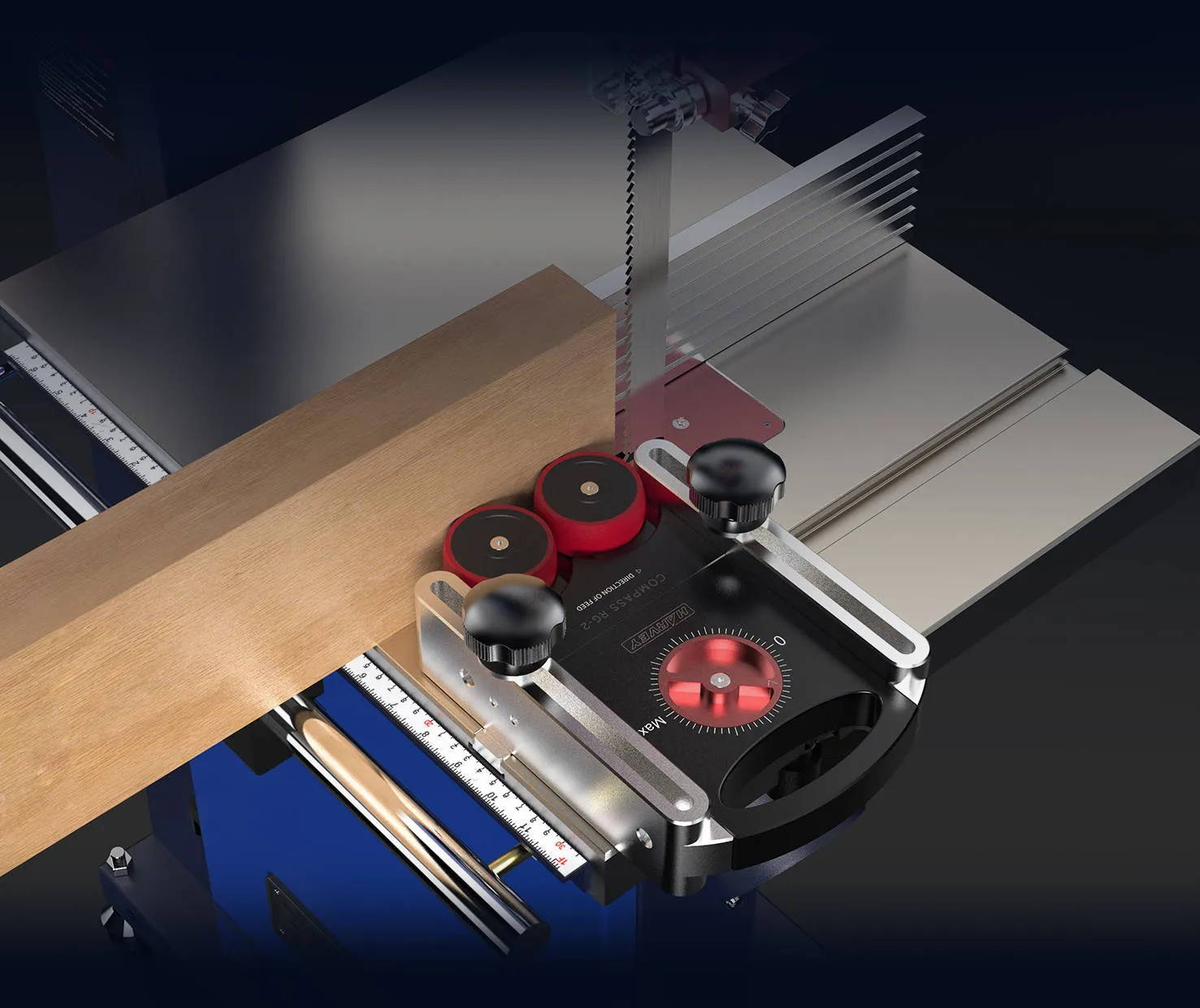

Comes with

the COMPASS RG-2 Roller Guide

In order to enhance the operation safety and user experience of the C14Pro, our newly developed COMPASS RG-2 Roller Guide is in- cluded as standard accessor. The main body of RG-2 is made of anodized aircraft-grade aluminum with high precision machining and beautiful anodizing.

The Compass RG-2 Roller Guide utilizes an 'Independent Suspension Mechanism where each roller has its own pre-loaded spring. This design enables the two guide rollers to adapt to dynamic stock surfaces with consistent holding pressure by moving independently

The Self-locking Cam Structure allows for precise holding force adjustment by rotating the knob to optimize pressure for specific cutting situations. It offers an adjustable range of approximately 15-22 lbs(70-100 N),suitable for various cutting scenarios.

Powerful Motor

The 3 HP TEFC, industrial grade motor supplies the robust power needed for the large capacities of this band saw.

Foot Brake with Micro Switch

Immediately stops the saw blade when needed.

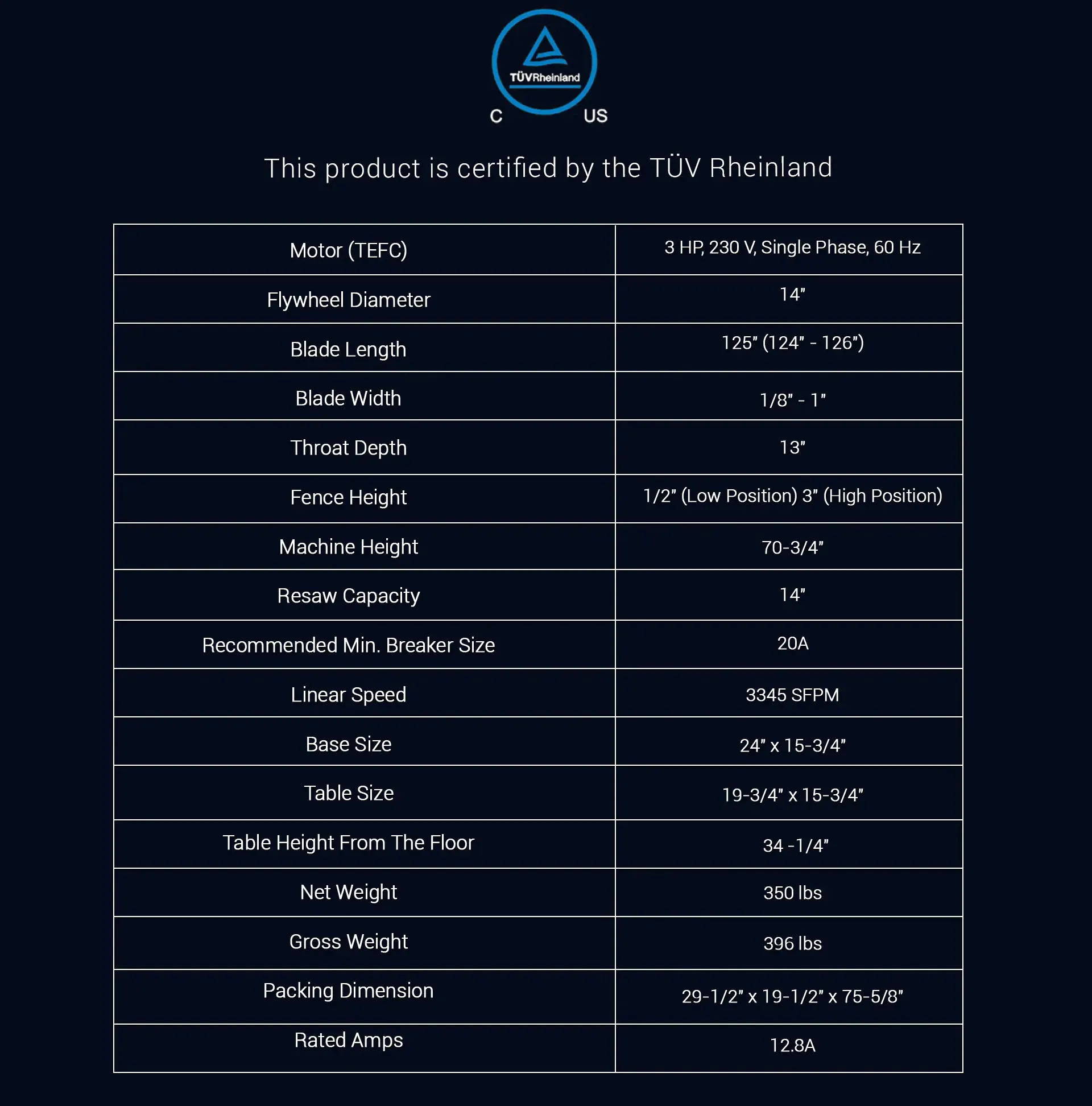

Specification

"Some images on this page are computer-generated representations of the product and may differ from the actual product. Colors, textures, and other details may not be accurately represented in the images. Please refer to the product description and specifications for more information."

Product Details:

Product Features and Benefits:

Nickel-Plated Worktable for Superior Rust and Wear Resistance (500-700HV Hardness)

Nickel-Plated Cast Iron Flywheels with Nickel-Plating for Mainte

nance-Free Rust Prevention

Nickel-Plated Cast Iron Rack and Pinion Table Tilting System

Dynamically Balanced Cast Iron Flywheels Ensure Smooth Operation and Superior Momentum

Reinforced Solid Steel Frame Provides Remarkable Rigidity and Stability (Over 350 lbs Weight)

Powerful 3HP TEFC (Totally Enclosed Fan Cooled) Single Phase Industrial Grade Motor

Extraordinary 14" Resaw Capacity

Unique Tool-Less Upper and Lower Ball Bearing Blade Guides with Easy Access Lock Knobs

COMPASS RG-2 Roller Guide with Independent Suspension Mechanism

Self-Locking Cam Structure with Adjustable Holding Force (15-22 lbs / 70-100N)

Foot Brake with Micro Switch for Immediate Blade Stopping

Magnetic On/Off Switch for Enhanced Safety

Quick Release Tensioning Levers for Fast Blade Changes

Rack and Pinion Table Tilting System with Gas Piston Assistance

Precision Ground Cast Iron Table for Smooth Work Surface

Ball Bearing on Each Side of Blade and Back for Minimum Blade Movement

Superior Nickel Plating with Autocatalytic Process and Mid-Phosphorus Chemical Formula

Enhanced Wear Resistance and Rust Prevention Capabilities with Lustrous Finish

Harvey Uncompromising Fine Craftsmanship and Build Quality

Safety Features:

Foot Brake with Micro Switch for Instant Blade Stopping

Magnetic On/Off Switch for Enhanced Motor Control

Emergency Safety Features Built into Micro Switch System

Tool-Less Blade Guide Adjustments for Safe Operation

COMPASS RG-2 Roller Guide for Enhanced Operation Safety and User Experience

Reinforced Frame Design for Maximum Stability During Operation

Self-Locking Mechanisms for Secure Adjustments

Product Specifications:

Product Dimensions

Net Weight: 350 lb | 157 kg

Gross Weight (Packaged): 396 lb | 178 kg

Length: 24" | 610mm

Width: 15-3/4" | 400mm

Height: 70-3/4" | 1800mm

Base Dimensions (Footprint): 24" x 15-3/4" | 610mm x 400mm

Packing Dimensions: 29-1/2" x 19-1/2" x 75-5/8" | 749mm x 495mm x 1921mm

Motor

Horsepower: 3HP | 2.2 kW

Electric Phase: 1Ph | 1Ph

Voltage: 230V | 230V

Current: 12.8A Full-Load | 12.8A

Frequency: 60Hz | 60Hz

Motor Type: TEFC Industrial Grade | TEFC Industrial Grade

Circuit Breaker Required: 20A with RCD Module | 20A with RCD Module

Blade Information

Blade Width: 1/8" - 1" | 3-25mm

Blade Length: 125" | 3175mm

Blade Tension Range: Variable Quick Release | Variable Quick Release

Included Blade: 3/4" width | 19mm width

Cutting Capacities

Flywheel Diameter: 14" | 350mm

Maximum Cutting Height: 14" | 350mm

Throat Capacity: 13" | 330mm

Cutting Speed: 3445 FPM | 1050 m/min

Table Information

Table Size: 19-3/4" x 15-3/4" | 500mm x 400mm

Table Height from Ground: 34-1/4" | 870mm

Table Tilting Range and Angle: -15° to 45° | -15° to 45°

Table Material: Nickel-Plated Cast Iron | Nickel-Plated Cast Iron

Table Tilt System: Rack & Pinion with Gas Assist | Rack & Pinion with Gas Assist

Other Information

Frame Material: Reinforced Steel (350+ lbs) | Reinforced Steel (157+ kg)

Flywheel Material: Nickel-Plated Cast Iron | Nickel-Plated Cast Iron

Blade Guides: Ball Bearing Tool-Less | Ball Bearing Tool-Less

Dust Collection: Dual Ports (400 CFM min) | Dual Ports (680 m³/h min)

Roller Guide: COMPASS RG-2 Included | COMPASS RG-2 Included

Nickel Plating Hardness: 500-700HV | 500-700HV

Safety Features: Foot Brake + Magnetic Switch | Foot Brake + Magnetic Switch

Assembly Status: Partial Assembly Required | Partial Assembly Required

Fence System: Aluminum (1/2" & 3" heights) | Aluminum (12.5mm & 76mm heights)

Delivery Method: Freight on Pallet | Freight on Pallet

Frequently Asked Questions:

Product Overview & Features

What makes the Ambassador C14Pro bandsaw "stain-less" and how does the nickel plating work?

The C14Pro features advanced nickel plating technology on the table, flywheels, and rack/pinion system. This autocatalytic plating process uses a mid-phosphorus chemical nickel formula that achieves 500-700HV hardness, providing superior rust and wear resistance. Under normal usage conditions, the nickel-plated surfaces maintain rust prevention performance for years, even in highly humid environments.

What is the maximum resaw capacity and what size materials can I cut?

The bandsaw has a 14" resaw capacity with a 13" throat capacity. The work table measures 19-3/4" × 15-3/4" (500×400mm), providing ample support for large workpieces.

What type of power requirements does the 3HP motor need?

Requires 230V single-phase power, 60Hz frequency, with 12.8A full-load current. Needs a 20A circuit breaker with RCD module for electrical shock protection. All electrical connections must be made by a qualified electrician.

How much space do I need for this bandsaw and how much does it weigh?

Total dimensions: 24" × 15-3/4" footprint, 70-3/4" total height. Net weight is 350 lbs (157 kg). Work table height is 34-1/4" (870mm).

What is the COMPASS RG-2 Roller Guide and why is it included?

The COMPASS RG-2 is a precision roller guide made of anodized aircraft-grade aluminum. It features an "Independent Suspension Mechanism" where each roller has its own pre-loaded spring, allowing adaptation to dynamic stock surfaces. The self-locking cam structure provides adjustable holding force of 15-22 lbs (70-100N) for enhanced safety and cutting precision.

Operation & Specifications

How do the tool-less blade guides work and what maintenance do they require?

The ball bearing blade guides feature tool-less adjustment knobs for easy access. Each guide has ball bearings on both sides and back of the blade. Guides should be positioned 1/64" (0.4mm) behind the blade's gullet and approximately 0.004" (0.1mm) from the blade sides. Regular cleaning and checking for wear is recommended.

What is the table tilting range and how smooth is the adjustment?

Table tilts from 45° right to -15° left using a rack and pinion system. Gas pistons assist with micro-adjustments for smooth operation. Includes preset stops at 90°, 45°, and -15° positions.

How does the foot brake system work and what safety features are included?

The foot brake stops the blade in approximately 4 seconds when pressed (much faster than coasting). Features a micro switch for safety. Also includes magnetic on/off switch and emergency stop capabilities.

What is the blade speed (FPM) and is it adjustable for different materials?

The blade speed is 3345 FPM (feet per minute) for the North American model. The speed is fixed and not adjustable for different materials. This speed is well-suited for general woodworking applications in both hardwood and softwood.

Technical Specifications & Setup

How long does the nickel plating last and what happens if it gets damaged?

Under normal usage conditions, the nickel-plated surfaces maintain rust prevention performance for years, even in highly humid working environments. The coating achieves 500-700HV hardness for extreme durability. If damaged, the affected area would need professional re-plating or component replacement.

Can Ambassador C14Pro bandsaw handle both hardwood and softwood resawing effectively?

Yes, the 3HP motor and 14" resaw capacity handle both materials effectively. The powerful motor provides sufficient torque for dense hardwoods, while precision ball bearing blade guides ensure clean cuts in softer materials.

How difficult is assembly and are professional setup services available?

Partial assembly required including: mounting stand pads, installing work table, spring assembly, rip fence, blade installation, and motor mounting. Detailed instructions with diagrams are provided.

What accessories are included vs. what needs to be purchased separately?

Included: Band saw, fence assembly, user manual, stand pads, hardware kit, hex wrenches (2mm-6mm), tool storage hook, and 3/4" blade. Separate purchases: Additional blades, mobile bases, specialized jigs, and aftermarket accessories.

How does the dust collection work and what size dust port does it have?

Features two dust collection ports - upper and lower. Recommends dust collection system with minimum 400 CFM capacity. Specific port diameters not stated in manual, though user feedback suggests 4" compatibility.

What is the difference between the Ambassador C14Pro bandsaw and other Harvey bandsaw models?

The C14Pro features advanced nickel plating technology on table, flywheels, and rack/pinion system. The "Stain-less" designation refers specifically to this rust-prevention technology, differentiating it from standard Harvey bandsaw models.

Can the upper wheel be adjusted for blade tracking and how precise is it?

Yes, features precise tracking adjustment using tracking knob and locking mechanism. Adjustment is "sensitive" and should be done "in small increments" while observing blade position through the tracking window. Clockwise moves blade toward rear, counterclockwise toward front. Dynamically balanced flywheels help maintain accurate tracking.

What is the maximum blade width the Ambassador C14Pro bandsaw can accommodate?

The blade width range is 1/8" - 1" (3-25mm), so the maximum blade width is 1 inch.

How quiet is the Ambassador C14Pro bandsaw compared to other 3HP bandsaws?

Dynamically balanced cast iron flywheels ensure smooth operation, minimal noise, and superior momentum. Heavy construction (350+ lbs) and precision engineering contribute to reduced vibration and noise compared to lighter bandsaws.

What blade sizes are compatible and are replacement blades readily available?

The Ambassador C14Pro bandsaw uses 125" (3175mm) blade length, width range 1/8" - 1" (3-25mm). Standard bandsaw blade suppliers typically stock these common sizes. The unit comes with a 3/4" blade included.

Safety Questions

What safety equipment should I wear when operating the Ambassador C14Pro bandsaw?

Always wear protective glasses. Remove ties, rings, watches, and jewelry. Roll sleeves past elbows, remove loose clothing, and confine long hair. Keep visitors at safe distance and prohibit children from work area.

How close should the upper blade guide be to my workpiece?

Position the upper blade guide approximately 1/4" above the workpiece. Adjust the guide post so the blade guides are just above the workpiece, allowing minimum blade exposure while maintaining proper support.

What should I do if the blade gets stuck in the wood during cutting?

Turn off power immediately if the blade is stuck in wood after cutting. Wait for the blade to come to a complete stop before attempting to remove the workpiece or make adjustments.

Can I leave the Ambassador C14Pro bandsaw running unattended?

No. Never leave the machine running unattended. Turn the power off and do not leave the bandsaw until the blade comes to a complete stop.

How should I properly feed material into the blade to avoid kickback?

Hold the stock firmly and feed it at a stable speed. Do not force the workpiece into the blade. Use push-sticks, hold-downs, or similar devices to keep hands away from the blade. Push slowly while keeping material pressed against the fence or miter gauge.

What precautions should I take when changing blades?

Always wear gloves and safety glasses when handling blades. Disconnect from the power source first. New blades are coiled - uncoil slowly and carefully. Release the blade tension before removal and ensure all guards are properly reinstalled.

Is it safe to cut round or cylindrical stock on this bandsaw?

No. Never cut round stock without an appropriate supporting tool. Round stock requires proper jigs or fixtures to prevent rotation during cutting.

What electrical safety requirements does this bandsaw have?

You must be properly grounded. This requires a 230V single-phase with 20A circuit breaker and RCD module for electrical shock protection. All electrical connections must be made by qualified electricians following local codes.

How should I position my hands and body when operating the saw?

Keep your hands and fingers away from the blade at all times. Use push-sticks for narrow pieces. Don't get too close to the workspace. Always ensure the switch is OFF before connecting to power to avoid accidental activation.

What should I do if the blade gets stuck in the wood during cutting?

Turn off the power immediately if the blade is still in the wood after cutting. Wait for the blade to come to a complete stop before attempting to remove the workpiece or make any adjustments.

Product Specification Questions

What are the complete motor specifications for the Ambassador C14Pro bandsaw?

3HP (2.2kW) TEFC industrial-grade motor, 230V single-phase, 60Hz frequency, 12.8A full-load current. Requires 20A circuit breaker with RCD module for electrical safety.

What are the exact cutting capacities and throat dimensions?

Maximum resaw capacity: 14" (350mm). Throat capacity: 13" (330mm). Maximum cutting height: 14" (350mm). These dimensions determine the largest stock you can process.

What are the complete table specifications and dimensions?

Work table size: 19-3/4" × 15-3/4" (500×400mm). Table height: 34-1/4" (870mm). Table tilts 45° right to -15° left. Features cast iron construction with nickel plating for rust resistance.

What blade specifications does this bandsaw require?

Blade length: 125" (3175mm). Blade width range: 1/8" - 1" (3-25mm). Blade speed: 3345 FPM (1050 MPM). Includes 3/4" blade. Uses standard 14" bandsaw blade specifications.

What are the overall dimensions and weight specifications?

Footprint: 24" × 15-3/4" (610×400mm). Total height: 70-3/4" (1800mm). Net weight: 350 lbs (157kg). Shipping weight: 396 lbs (178kg). Packing dimensions: 29-1/2" × 19-1/2" × 75-5/8".

What are the wheel and flywheel specifications?

Wheel diameter: 14" (350mm). Features heavy-duty cast iron flywheels with nickel plating. Dynamically balanced for smooth operation and minimal vibration. Upper and lower wheels are precision-engineered for accurate blade tracking.

What are the dust collection system specifications?

Dual dust ports (upper and lower). Recommended dust collector capacity: minimum 400 CFM. Ports designed for standard 4" dust collection hose compatibility based on user feedback.

What are the fence system specifications and capabilities?

Fence plate heights: 1/2" and 3" (14mm and 80mm) positions available. Aluminum construction with rack and pinion positioning system. Includes precision cursor with zero-setting capability for accurate measurements and repeatable cuts.

CUSTOMER TESTIMONIALS

YOU MAY ALSO LIKE...