Patent Notice: This product is protected by one or more patents.

"Some images on this page are computer-generated representations of the product and may differ from the actual product. Colors, textures, and other details may not be accurately represented in the images. Please refer to the product description and specifications for more information."

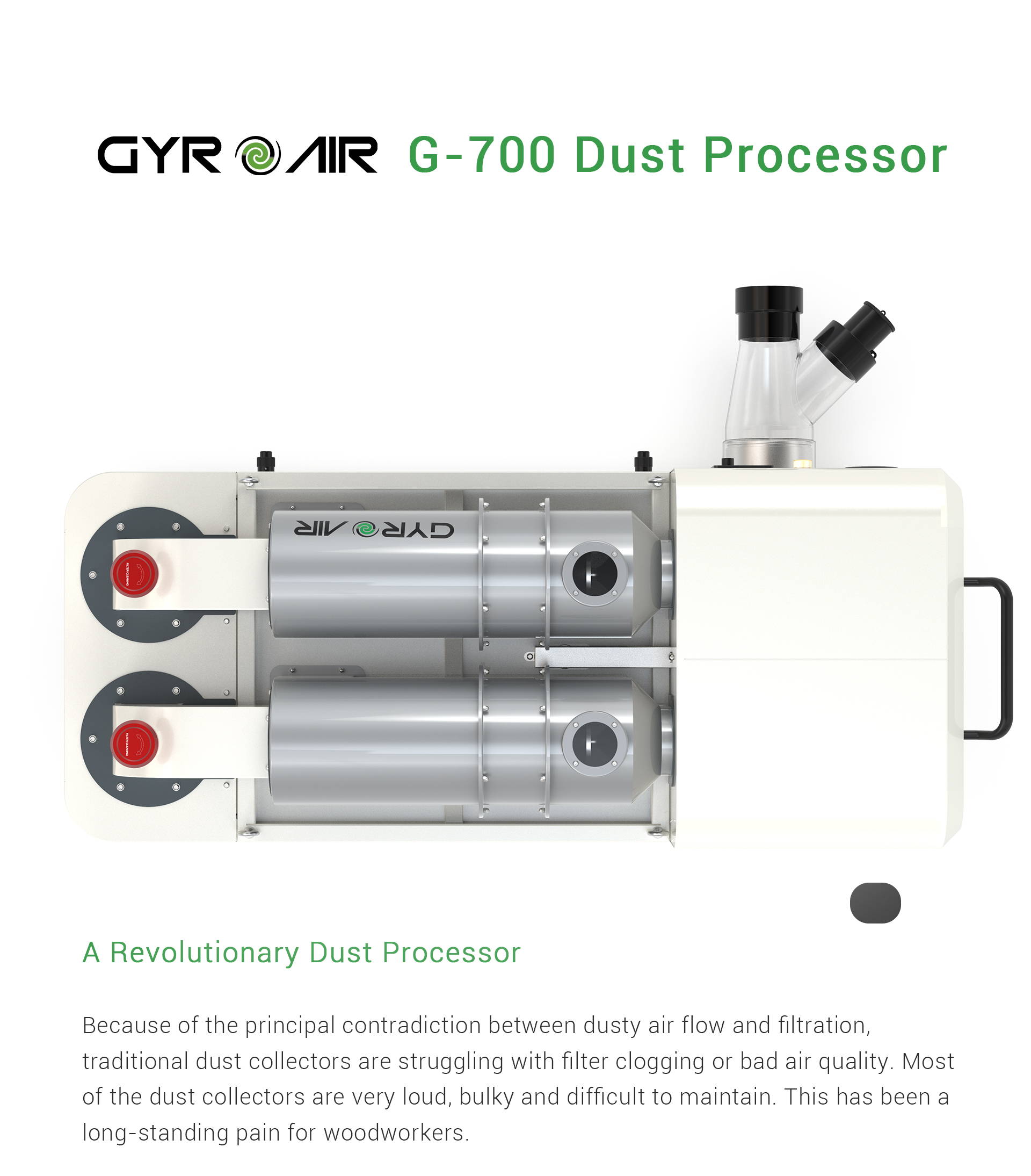

G-700

Wood Dust Processor

A Revolutionary Dust Processor

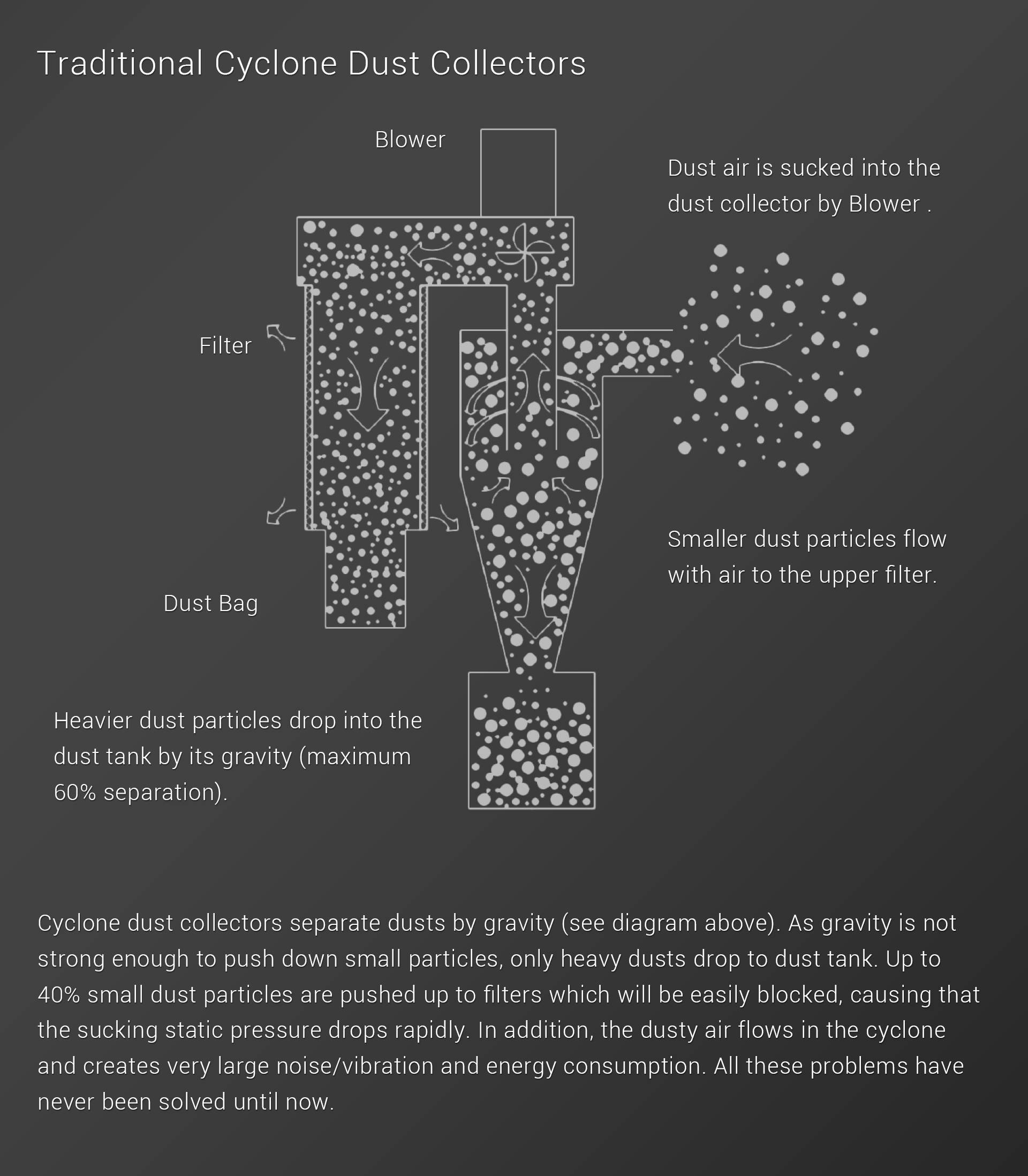

Because of the principal contradiction between dusty air flow and filtration, traditional dust collectors are struggling with filter clogging or bad air quality. Most of the dust collectors are very loud, bulky and difficult to maintain. This has been a long-standing pain for woodworkers.

To solve this problem, the Harvey team of engineers spent

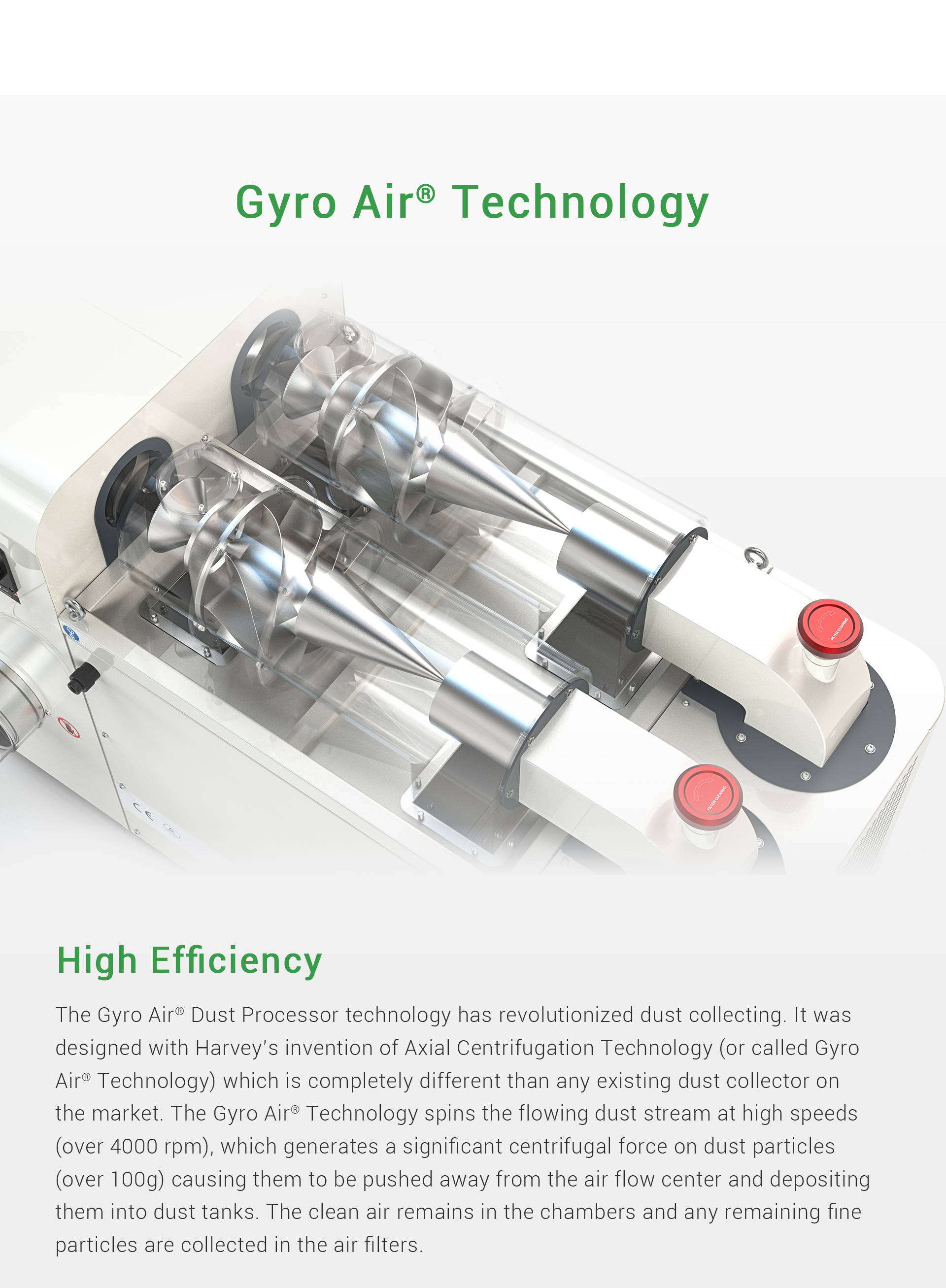

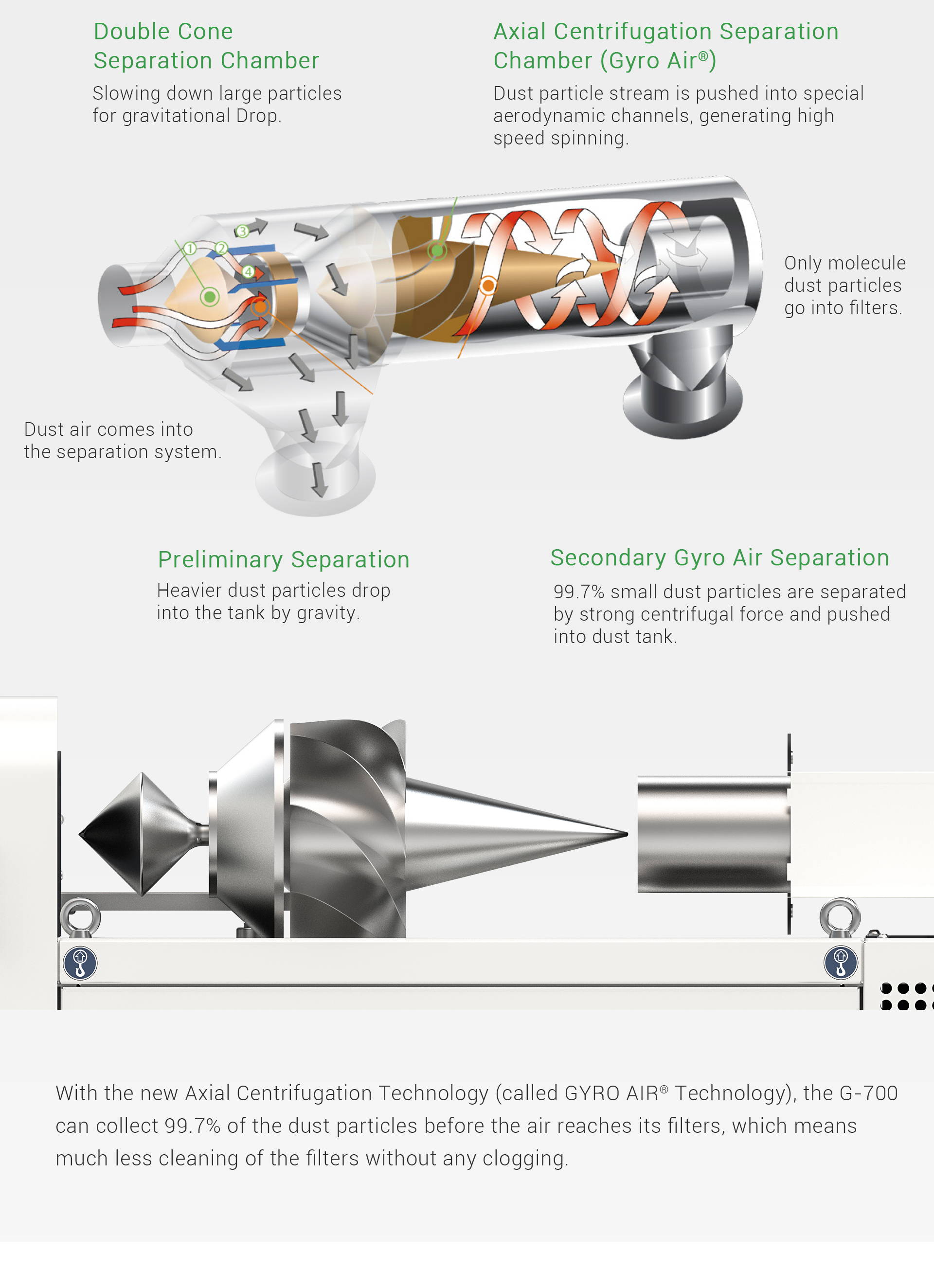

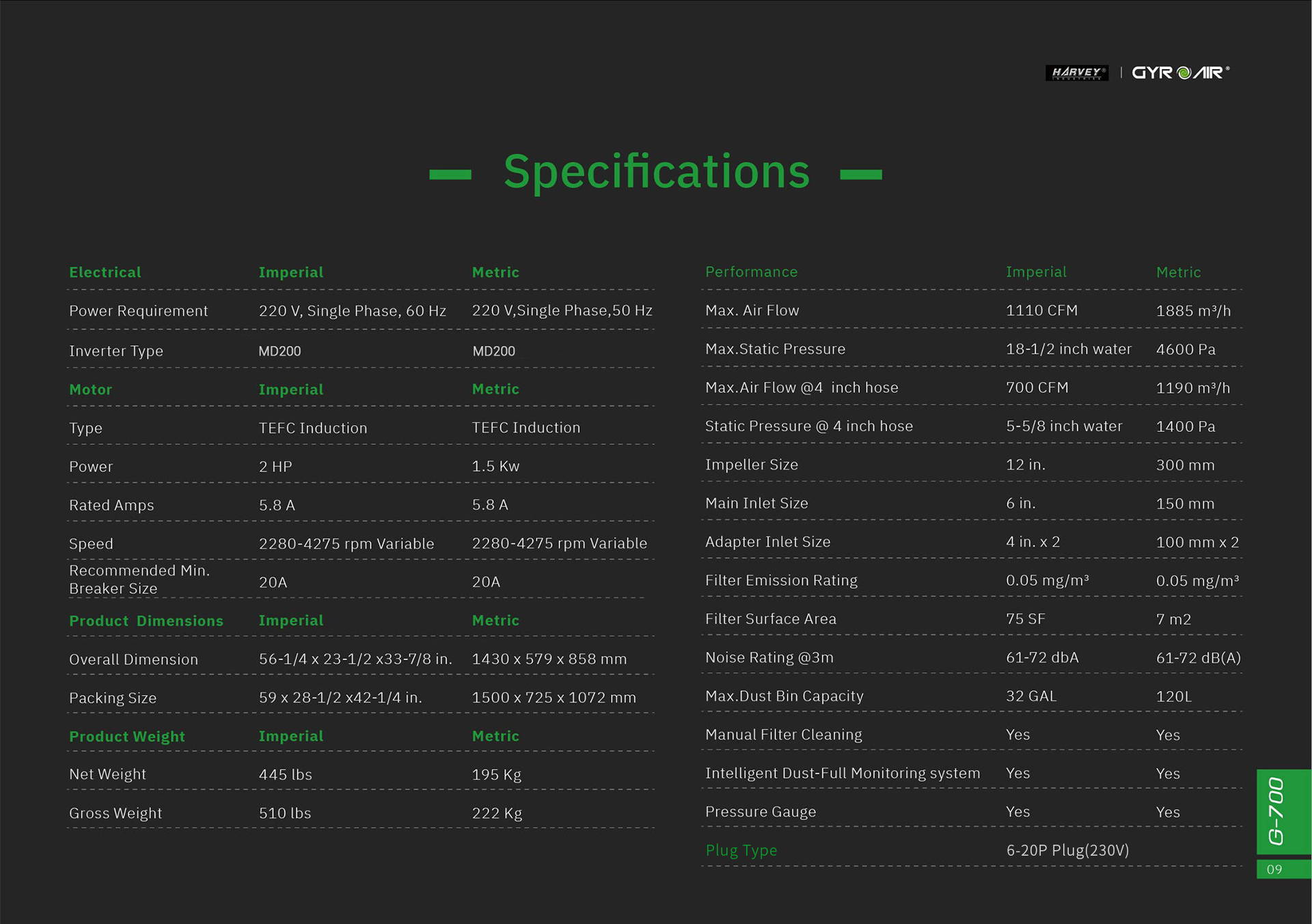

over 7 years of research and study, to develop an unprecedented Dust Collector, the Gyro Air® G-700 Wood Dust Processor. The G-700 Gyro Air® Wood Dust Processor incorporates a unique, patented technology to separate dust particles from the air and capture them before they enter the filters.The G-700 uses the new Axial Centrifugation Technology (called Gyro Air® Technology), to spin the air/dust stream up to 4,000 RPM and generate a super strong centrifugal force (over 100 times gravity) to separate the dust from the air and collect it in two dust bins hidden internally in the unit.

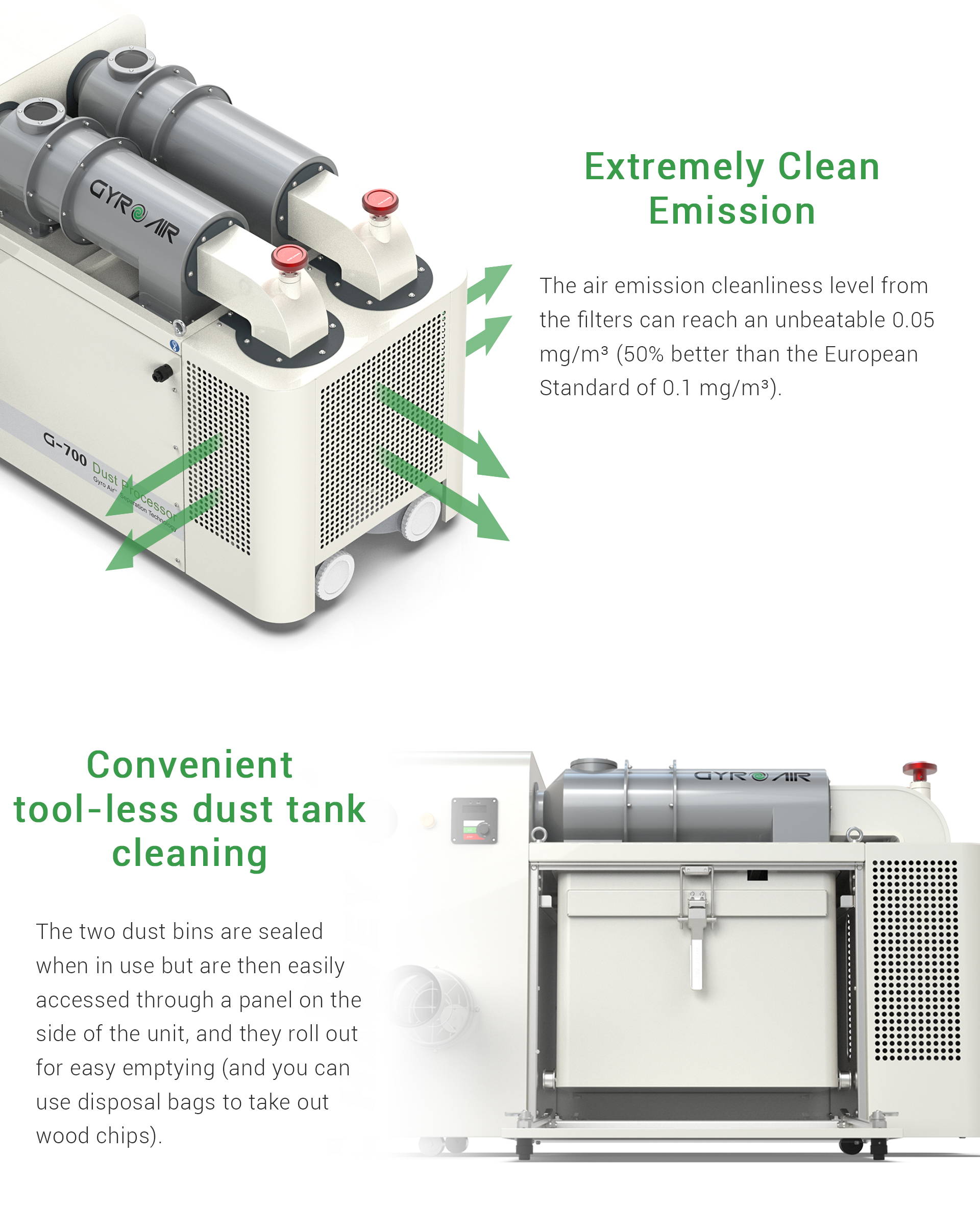

The G-700 collects 99.7% of the dust particles before the air reaches its HEPA filters. This not only means much less cleaning of the filters, but that the airflow and static pressure will remain much more constant during operation. In addition, the air emission cleanliness level from the filters can reach an unbeatable 0.05 mg/cubic meter (50% better than the European Standard of 0.1 mg/cubic meter). The entire extraction system is aerodynamically optimized with extraordinary running efficiency, so it can save up to 50% in energy costs.

The Gyro Air® technology and its unique aerodynamic design allow the G-700 Gyro Air® to run at an incredibly low noise level of 61 to 72 dBA, depending on which speed you run the Gyro Air ... yes, it is a variable-speed machine that allows you to adjust the airflow to suit your needs. The G-700 is powered and controlled by a SIEMENS industrial 2HP motor and SIEMENS V20 Variable Frequency Driver for 24/7 applications. In addition, the Gyro Air® G-700 is equipped with a built-in Dust-Bin monitor and a Remote Control Key. Its fully enclosed housing is short enough to fit under most benches, and it has heavy-duty casters to allow it to move as needed. The two dust bins are sealed when in use but are then easily accessed through a panel on the side of the unit, and they roll out for easy emptying (and you can use disposal bags to take out wood chips).

CUSTOMER TESTIMONIALS

DID YOU BUY A G700? WE WANT TO HEAR FROM YOU! LET US KNOW HOW YOU LIKE THE DUST PROCESSOR, AND IF YOU NEED ANY ASSISTANCE WITH IT.

YOU MAY ALSO LIKE...