S-10

Universal Overhead Guard

Protection That Moves With You

In every workshop, amidst the humming machines and the sounds of creation, a presence lingers—just out of sight, but never out of mind: safety. With the SHARK S-10 Universal Overhead Guard, Harvey brings that presence into focus. Precision-crafted and purpose-built, the SHARK S-10 transforms your table saw experience—delivering protection without compromise.

Designed with both form and function in mind, the SHARK S-10 elevates routine table saw work into a process that’s smoother, more streamlined, and fundamentally safer. It moves with you, lifts at a touch, and stays aligned with every pass. While your eyes remain on the cut, the SHARK handles the rest—controlling dust, gliding over your workpiece, and ensuring that every moment at the saw is as precise as it is protected.

From the weekend warrior chasing clean results to the professional builder working to exacting standards, the SHARK S-10 doesn’t just safeguard—it works in harmony with every cut you make.

Lightweight, Rail-Mounted Design

Tri-Axis Adjustment, Positioned for Precision

Telescopic Reach, Designed to Fit In

Air-Spring Lift, Effortless Movement

Integrated Dust Collection, Clean by Design

Stable Roller, Glide with Confidence

Standard Dual Guards, Versatile Cutting

Clear-Away Access, Swings Out of the Way

Premium Materials, Engineered for the Long Haul

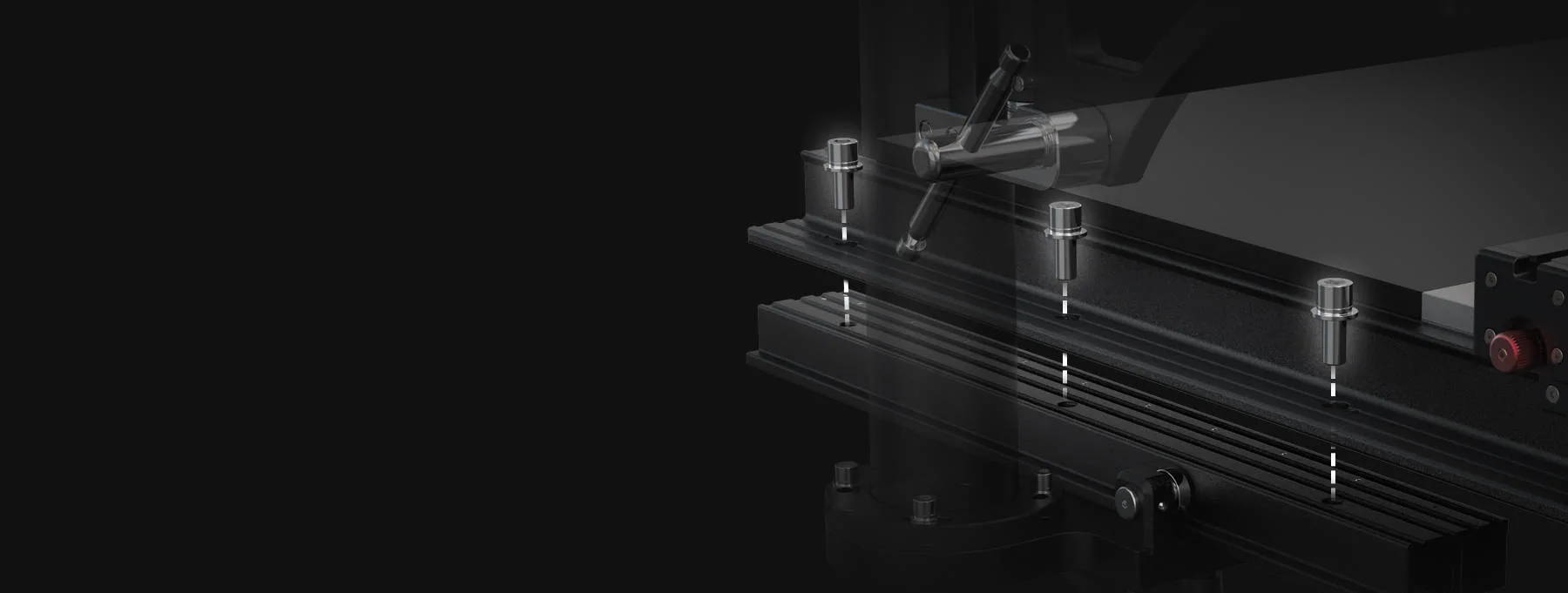

Lightweight,

Rail-Mounted Design

Built for quick installation and seamless integration, the SHARK S-10 mounts directly to your table saw’s rear rail—minimizing footprint while maximizing flexibility.

The rail-mounted design allows you to slide the entire assembly aside by loosening two locking handles, giving you room to work with a router table attachment or full access to your saw's maximum rip capacity. When space is tight or versatility is key, the SHARK adapts without getting in the way.

The SHARK S-10 can be installed easily and quickly on any table saw equipped with an L-shaped rear rail, allowing users to upgrade their saws with minimal effort and enjoy enhanced safety and functionality right away.

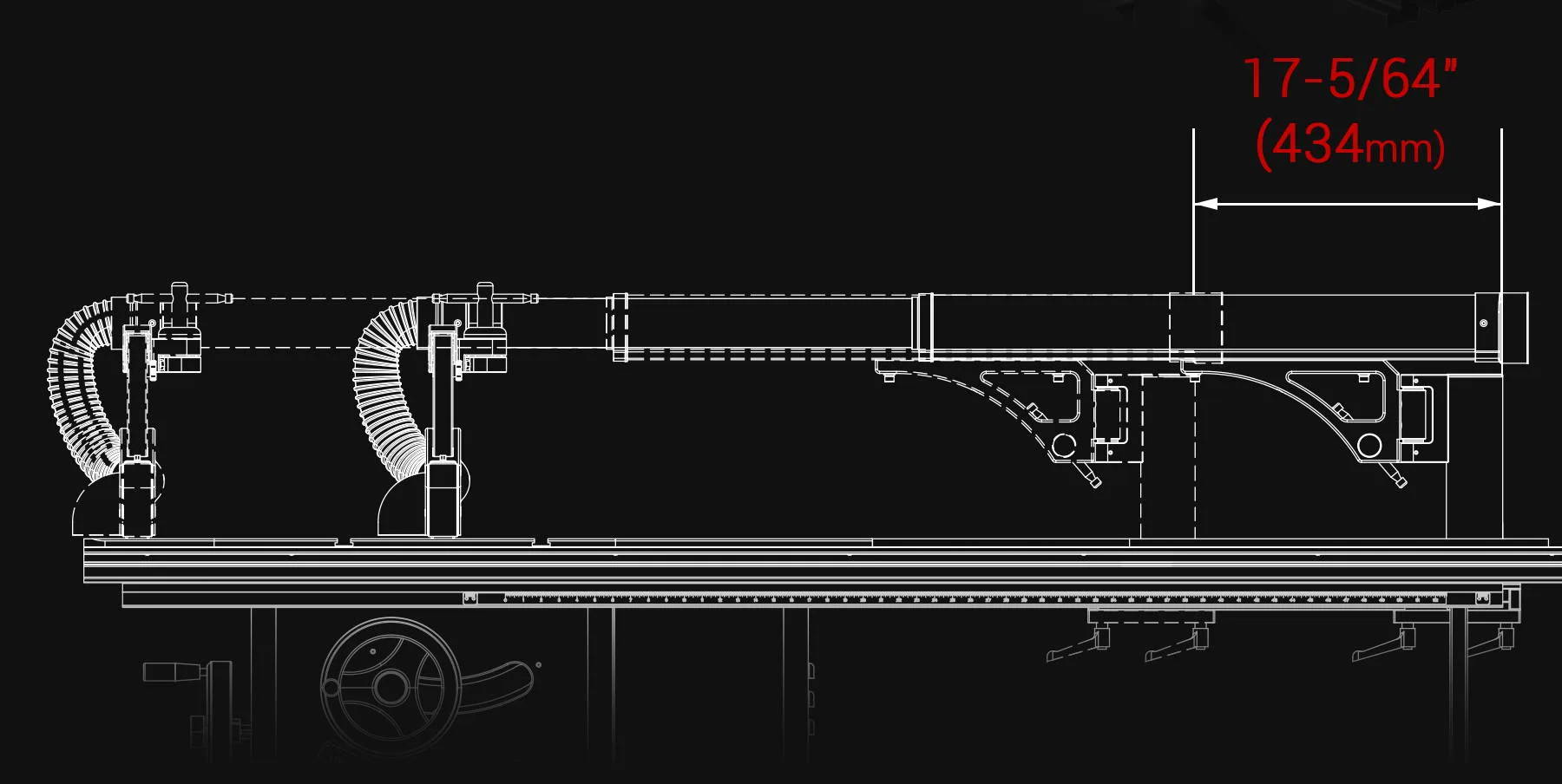

17-5/64" (434 mm) range of motion

Tri-Axis Adjustment,

Positioned for Precision

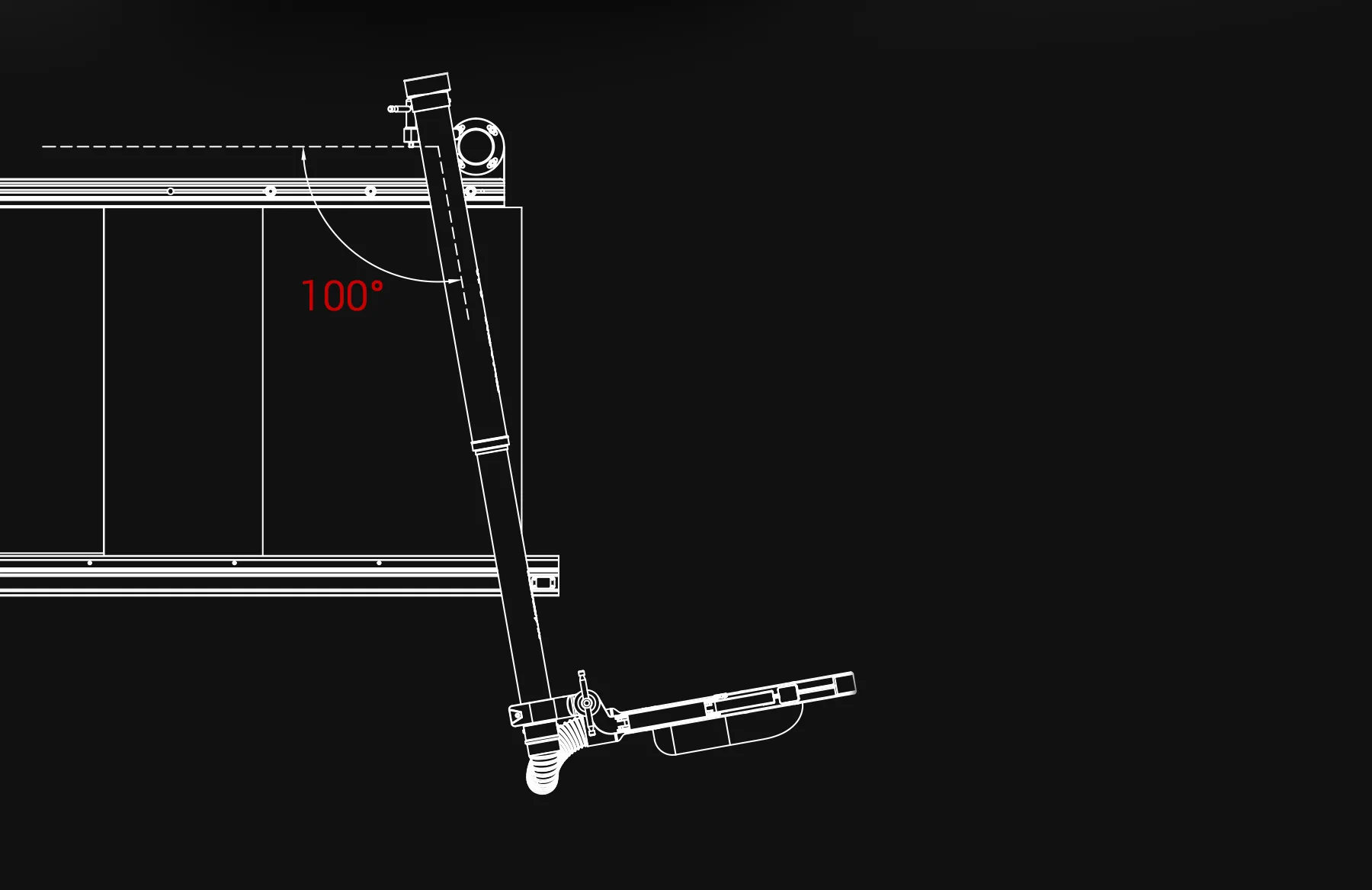

With tri-axis articulation, the SHARK S-10 lets you adjust the guard’s position, placing it exactly where it needs to be, no matter your setup. It’s not just adjustable—it’s responsive, adapting to your workflow with exacting accuracy.

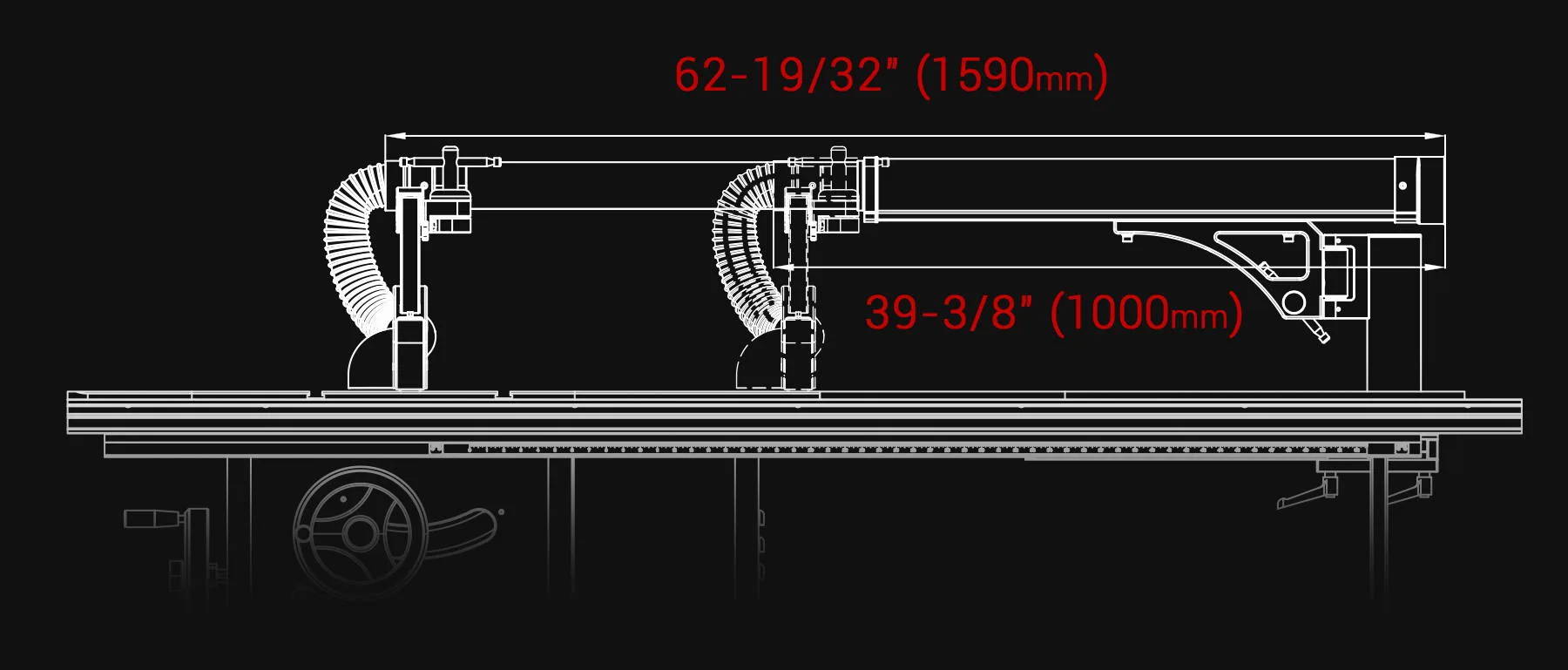

Telescopic Reach,

Designed to Fit In

A smoothly extending upper arm spans from 1,000 mm to 1,590 mm (39-3/8" to 62-19/32"), offering a full 590 mm (23-7/32") range of motion. This broad reach ensures compatibility across a wide range of table saws—whether in compact home shops or full-scale professional spaces.

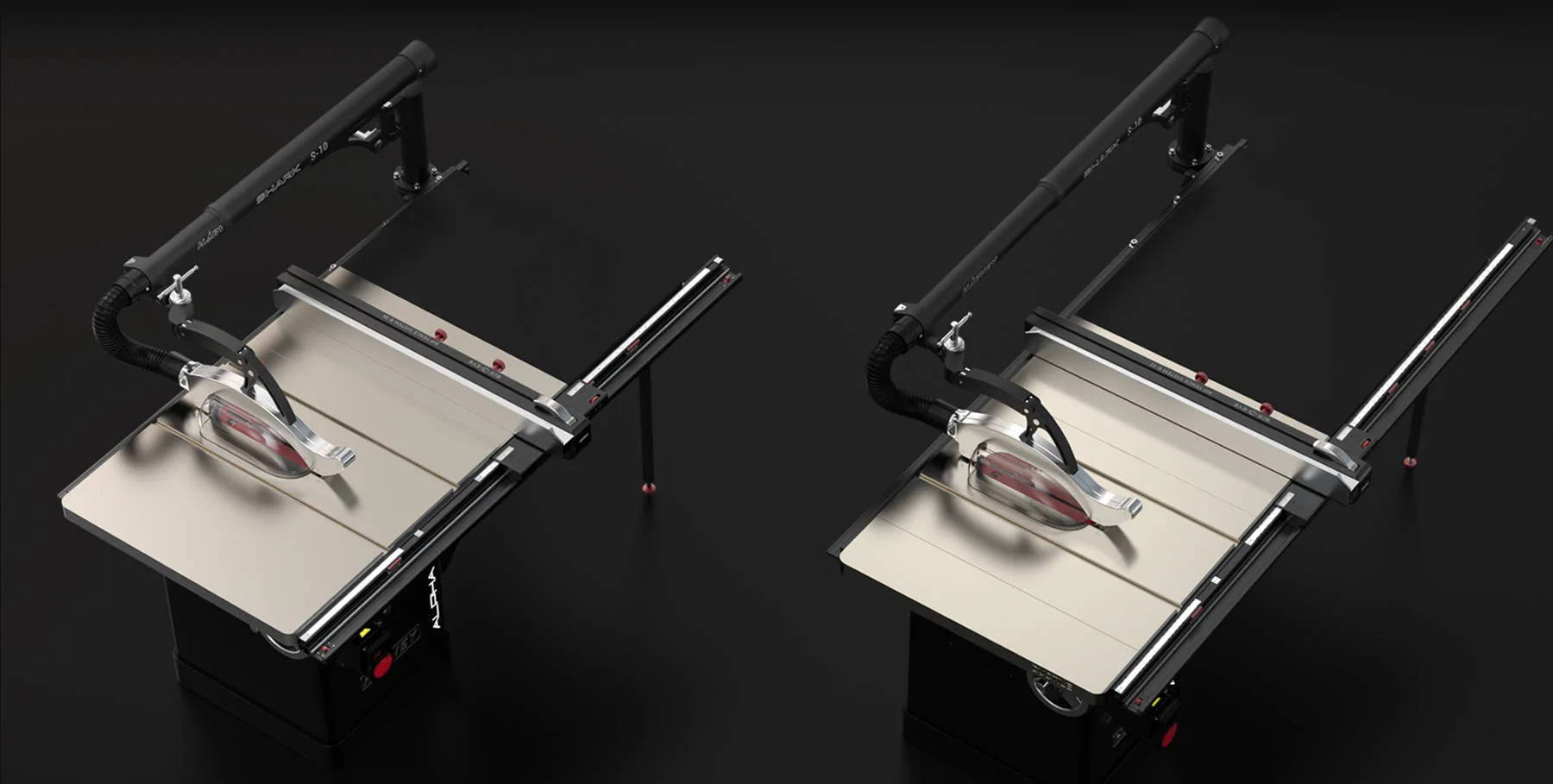

HW110S-36Pro

with SHARK S-10 Universal Overhead Guard

HW110S-52Pro

with SHARK S-10 Universal Overhead Guard

Together, the SHARK’s rail-mounted base, tri-axis articulation, and telescopic arm form a system engineered for the demands of real-world shops. Whether you’re navigating tight spaces, switching between tools, or adapting to unique project setups, the SHARK adjusts without resistance.

It offers a rare combination of stability and flexibility—staying out of your way when needed, yet always ready to engage. It’s not just a safety upgrade; it’s a fully integrated part of your workflow—versatile, unobtrusive, and universally ready to meet the needs of any workspace.

Air-Spring Lift,

Effortless Movement

No more clunky hardware or awkward adjustments. The air-spring linkage allows the guard to rise and lower with smooth, fluid motion—adding a level of control and finesse you can feel with every touch.

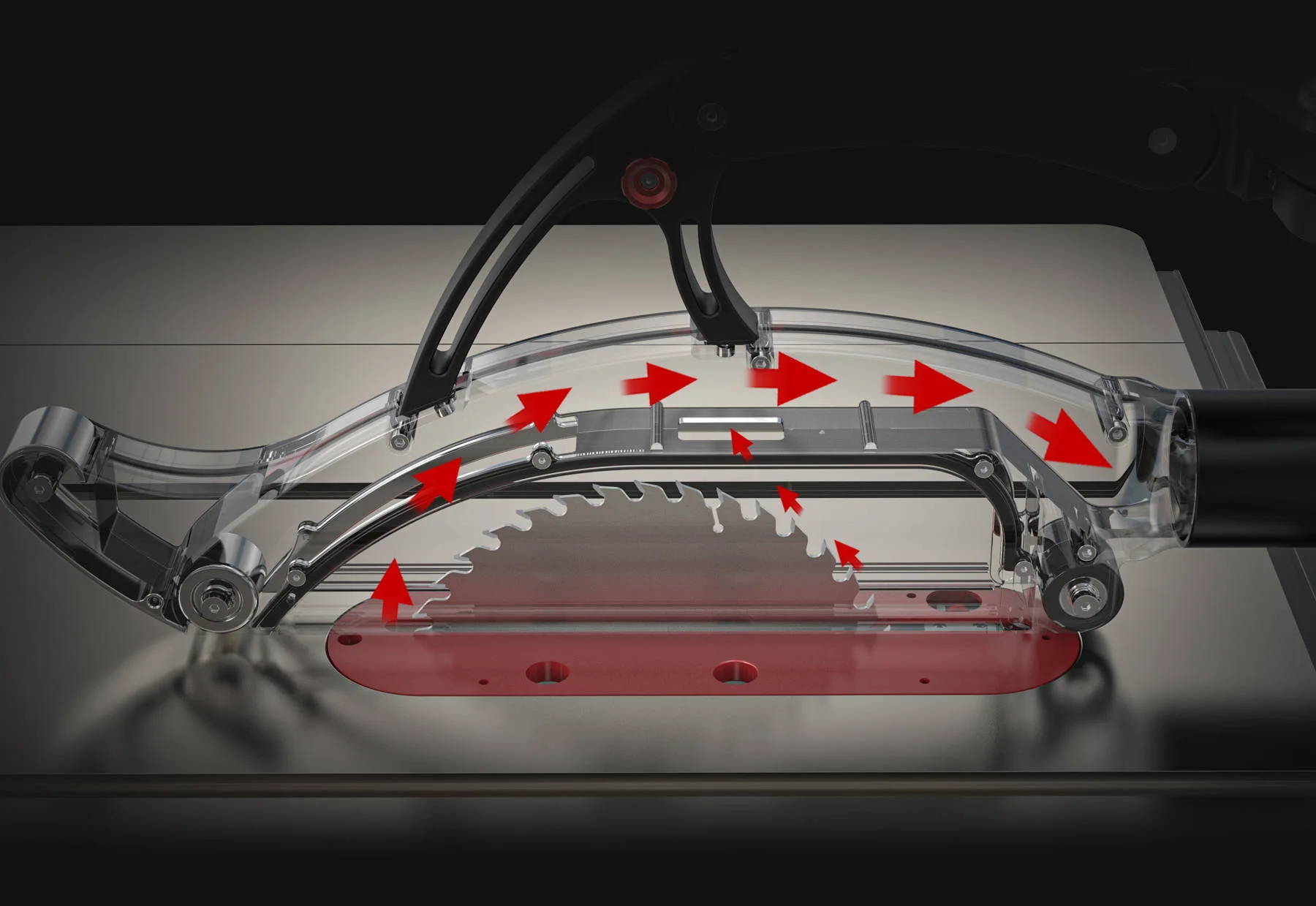

Integrated Dust Collection,

Clean by Design

An internal channel captures dust directly at the source, minimizing airborne particles and turning sawdust into neatly directed waste—helping maintain cleaner cuts, clearer air, and a tidier workspace.

Stable Roller,

Glide with Confidence

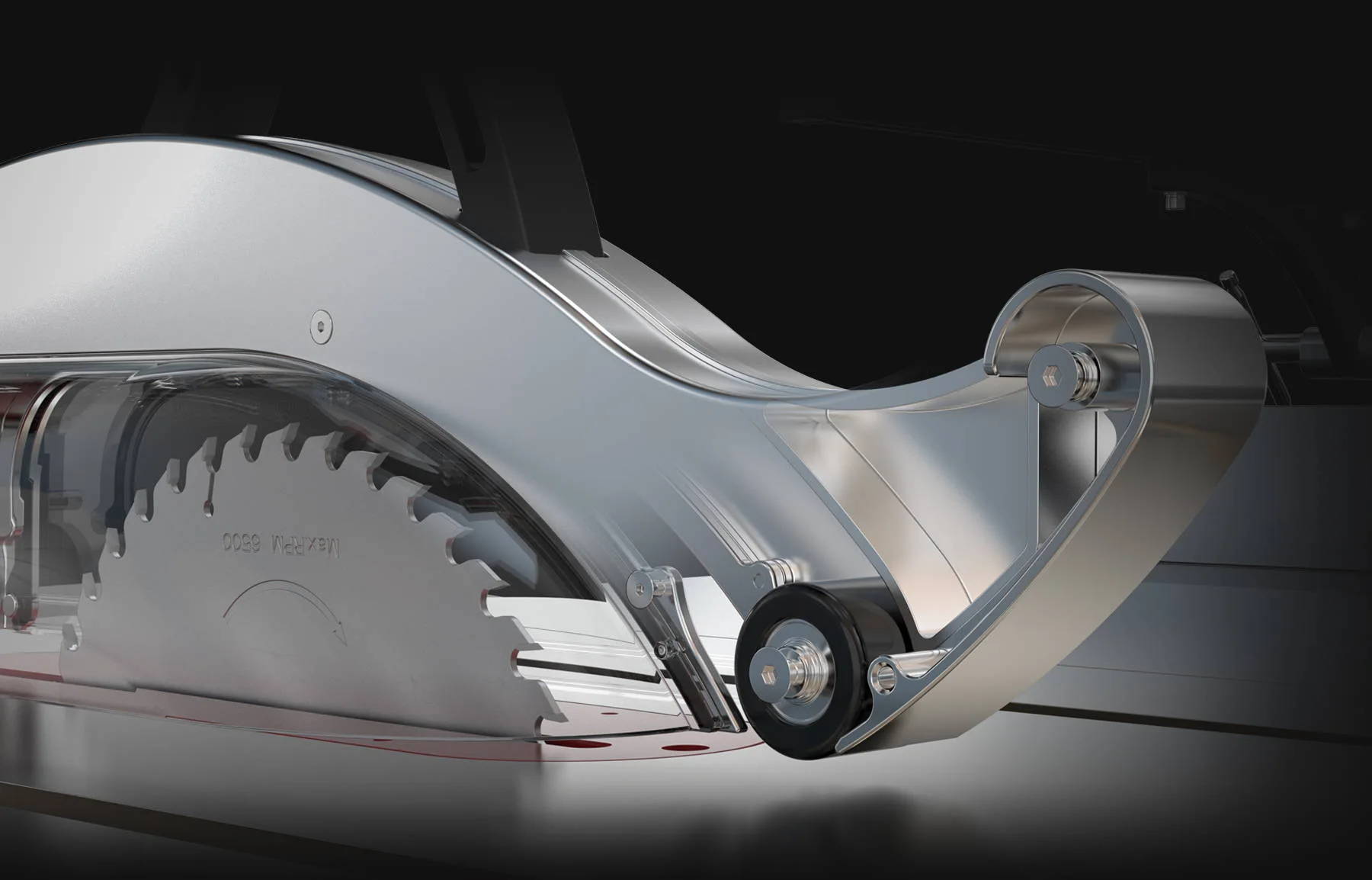

The all-new feed angle design delivers exceptionally smooth, resistance-free material feeding.

Integrated nylon roller reduces surface drag and resists wear—guiding material smoothly while protecting delicate stock from scratches and friction during feed.

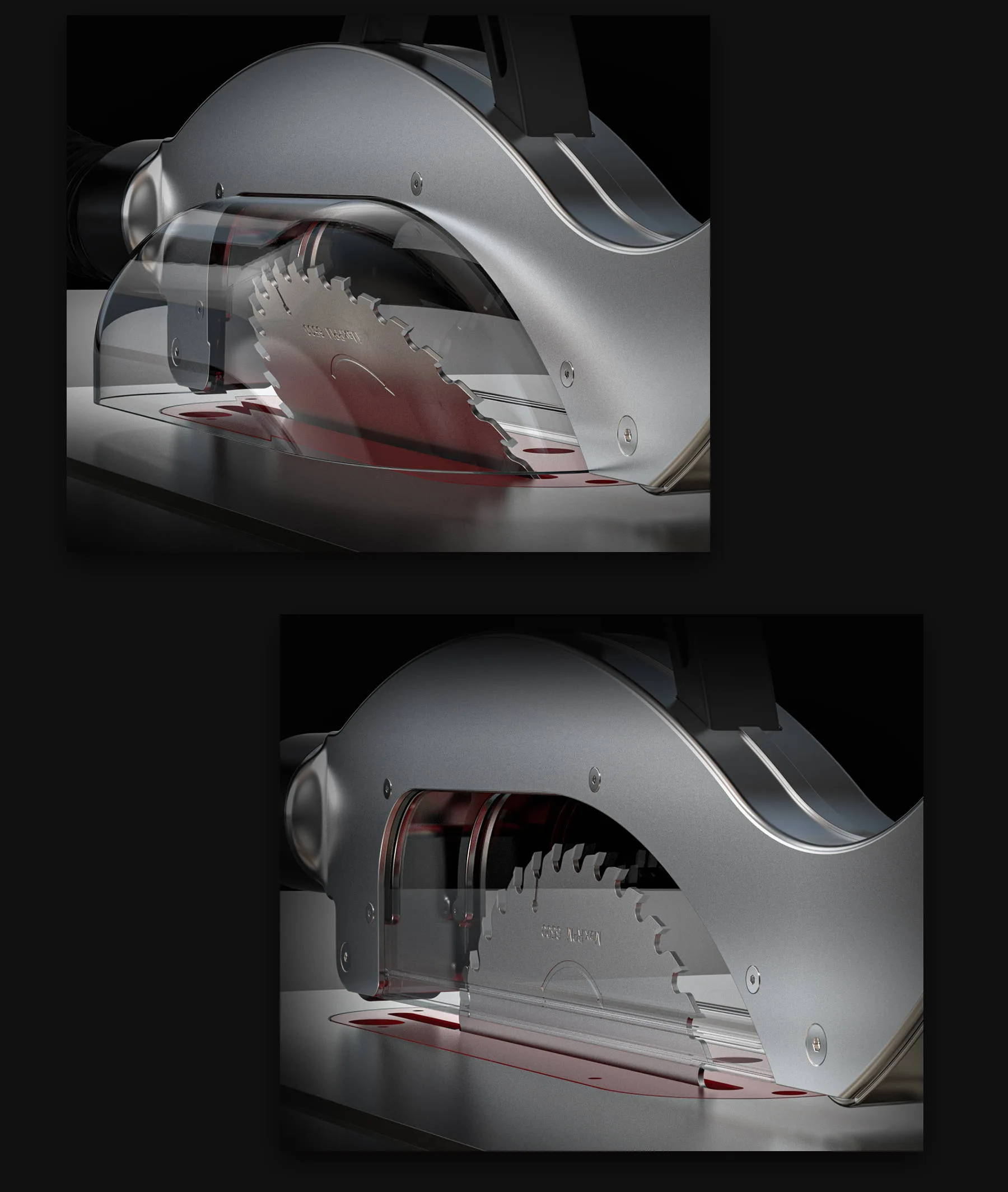

Standard Dual Guards,

Versatile Cutting

Standard with both flat and dome guards, the S-10 seamlessly transitions between 90° and bevel cuts, delivering precision and safety no matter how you tilt the blade.

Clear-Away Access,

Swings Out of the Way

When the cut demands an open table, the SHARK swings out of the way. With a quick adjustment, the guard pivots smoothly aside—leaving nothing between you and the task at hand.

Premium Materials,

Engineered for the Long Haul

The SHARK’s main body is forged from high-strength aluminum alloy for durability without excess weight.

The transparent guard is molded from impact-resistant polymer, and the roller is made of rugged, wear-resistant nylon. Every component is selected for reliability, performance, and years of trusted use.

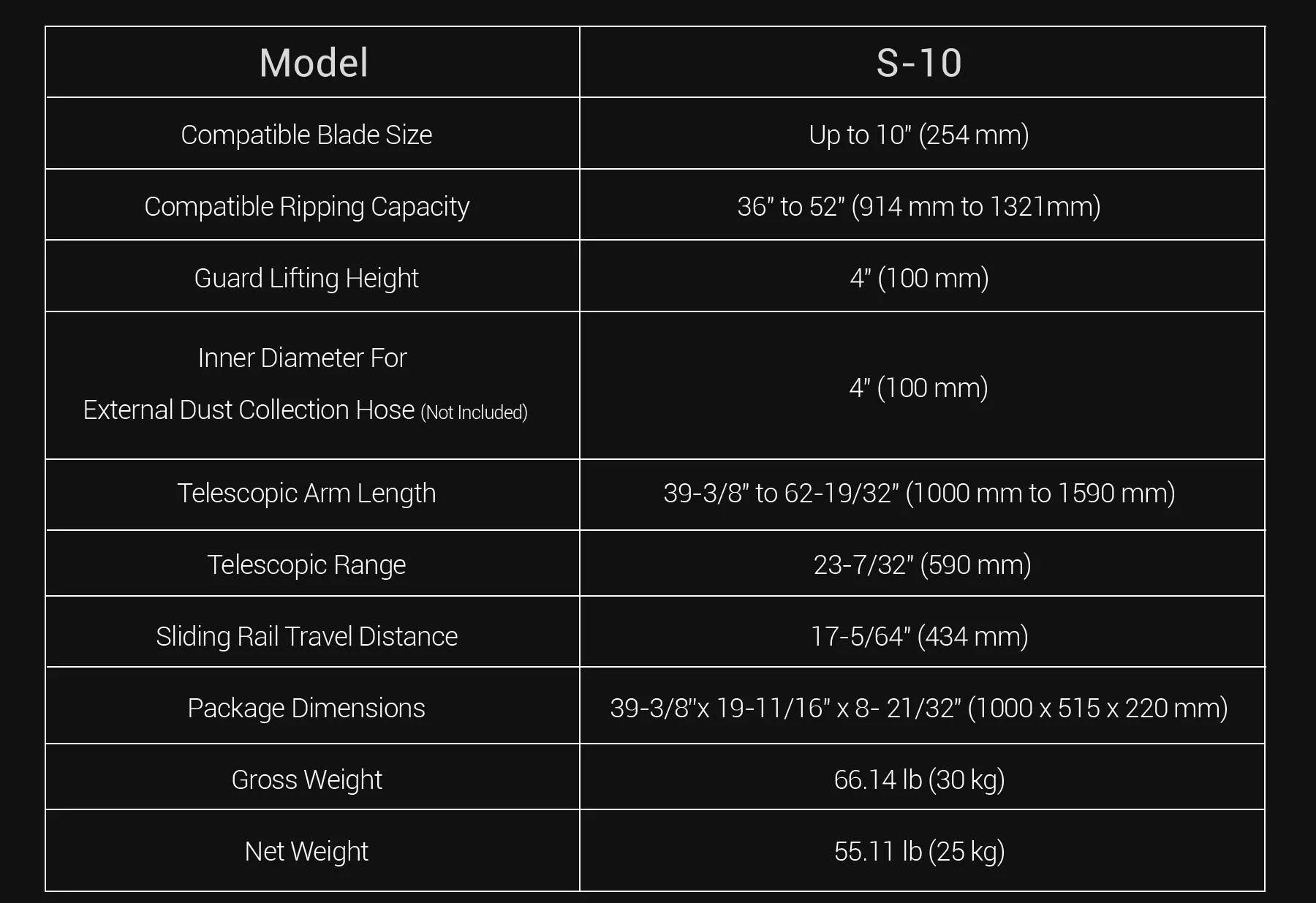

SPECIFICATIONS

*For certain saw models, drilling on the L-shaped rear rail may be required for installation.

"Some images on this page are computer-generated representations of the product and may differ from the actual product. Colors, textures, and other details may not be accurately represented in the images. Please refer to the product description and specifications for more information."