Best Bandsaws for Woodworking

At Harvey Woodworking, we're dedicated to providing the highest quality bandsaws, built with performance, precision, convenience, safety and reliability at the core of each of our products.

Being the OEM manufacturer for most major brands before creating our own products, we've mastered the art of making the best bandsaws on the market.

Let customers speak for us

What customers think about the store

Harvey Woodworking offers high-quality woodworking tools and accessories with exceptional engineering, durability, and precision. Their products, such as table saws, bandsaws, fences, miter gauges, and dust collectors, consistently receive praise for their sup...

AI-generated from customer reviews.

Key Takeaways:

Professional Resaw Capacity: Harvey Woodworking's ALPHA HW615Pro series bandsaws deliver exceptional 15" resaw capacity with stain-less nickel-plated surfaces, eliminating rust concerns while providing smooth, powerful cutting through the largest hardwood lumber.

Ultimate Rust Protection: Featuring the revolutionary Stain-less Nickel-Plating Technology and precision-engineered components, Harvey Woodworking's AMBASSADOR C14Pro bandsaws offer superior corrosion resistance with 500-700 HV hardness rating for decades of maintenance-free operation.

Precision Cutting Systems: Harvey Woodworking's ALPHA A-15 Intelligent bandsaws come equipped with advanced digital controls, tool-less blade guides, COMPASS RG-2 Roller Guides, and integrated dust collection systems for comprehensive cutting performance.

Why Choose Harvey Woodworking Bandsaws for Performance, Precision, Convenience, Safety and Reliability?

When resaw capacity and cutting precision matter in woodworking, Harvey Woodworking's bandsaw lineup sets the industry standard. These aren't just cutting tools—they're precision instruments designed for craftsmen who refuse to compromise on quality. Harvey's philosophy of "Good Enough is Not Enough" drives every engineering decision, resulting in bandsaws that deliver professional results whether you're a seasoned furniture maker or setting up your first serious workshop.

Harvey Woodworking's innovative approach addresses the most common frustrations in bandsaw operation: rust, blade drift, and fence accuracy. Their revolutionary stain-less nickel-plated surfaces eliminate corrosion concerns even in humid environments, while the massive cast iron flywheel construction provides the stability needed for smooth, accurate cuts. The result is a bandsaw that maintains its precision year after year, making it a true investment in your craft.

What makes Harvey Woodworking's bandsaws particularly compelling is their attention to the complete cutting experience. From the whisper-quiet 3HP motor operation to the tool-less blade guide adjustments, every detail is engineered to help you focus on your woodworking rather than fighting with your tools.

Key Features to Look for in Professional Bandsaws

Professional woodworking demands precision, reliability, and performance that stays consistent over thousands of cuts. Harvey Woodworking's bandsaw series incorporates the most critical features that separate professional-grade equipment from basic shop tools:

Revolutionary Stain-less Nickel-Plating Technology: The heart of Harvey Woodworking's rust protection advantage lies in their proprietary chemical nickel-plating process. This autocatalytic plating combines with mid-phosphorus chemical nickel formula to achieve 500-700 HV hardness rating, significantly enhancing wear resistance and rust prevention capabilities. This engineering breakthrough delivers table surfaces that remain smooth and lustrous indefinitely—protection that rivals dedicated industrial machinery.

Heavy-Duty Cast Iron Flywheel Construction: Harvey Woodworking's precision-balanced cast iron flywheels provide the mass and stability essential for smooth cutting through dense hardwoods. The substantial flywheel weight eliminates vibration while maintaining consistent blade speed, crucial for achieving glass-smooth resaw surfaces across different materials and grain patterns.

Tool-less Blade Guide Systems: The blade guide mechanism uses precision ball bearings on each side and back of the blade to eliminate blade deflection and drift. This system provides effortless guide adjustments without tools while maintaining perfect blade tracking, essential for consistent cut quality across different blade widths and cutting applications.

Industrial-Grade Motor Systems: Harvey Woodworking's bandsaws feature powerful 3HP TEFC motors designed for continuous operation. These precision-balanced motor systems deliver consistent power through the heaviest exotic hardwoods, while the integrated foot brake with micro-switch provides instant stopping power for enhanced safety.

Best Harvey Bandsaws for Every Woodworker Looking for Performance, Precision, Convenience, Safety and Reliability

ALPHA HW615Pro Series: Maximum Resaw Performance

The HW615Pro represents Harvey's ultimate resaw capability, combining 15" cutting height with cutting-edge stain-less technology. This powerhouse features a robust 3HP motor and precision-engineered components designed for demanding production environments.

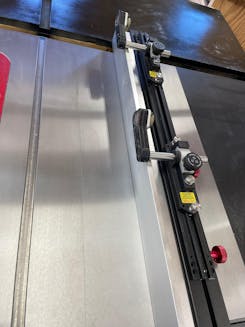

The nickel-plated 20" x 20" cast iron table provides a corrosion-resistant work surface that stays smooth and flat for decades. The integrated precision fence system ensures every resaw cut is accurate, while the tool-less blade guides deliver consistent tracking across all blade widths. Each saw comes equipped with Harvey's COMPASS RG-2 Roller Guide system, engineered for safe and enjoyable cutting through the largest lumber dimensions.

AMBASSADOR C14Pro Series: Compact Professional Power

For woodworkers who demand professional features in a more compact footprint, the C14Pro series delivers 14" resaw capacity through Harvey's advanced cabinet design. The revolutionary stain-less construction extends throughout the saw, including the rack and pinion tilting system that traditionally suffers from moisture exposure.

The massive steel frame construction (over 350 lbs) absorbs vibration while the precision rack and pinion table tilting system provides smooth, accurate bevel adjustments from 45° to -15°. These saws excel in smaller workshops where space is premium but performance cannot be compromised.

ALPHA A-15 Intelligent Series: Next-Generation Technology

At the pinnacle of Harvey's innovation, the A-15 series offers the first truly intelligent bandsaw with advanced digital controls and touchscreen interface. These cutting-edge saws incorporate every Harvey breakthrough, from precision-ground components to voice-controlled LED worklights.

The 7-inch touchscreen displays real-time blade tension, table tilt angle, and blade speed, while built-in sensors monitor all critical functions. The enhanced dust extraction system is fully enclosed within the cabinet for superior performance, while dual safety shutoff sensors ensure operation only when cabinet doors are properly closed.

How Harvey Bandsaws Transform Your Woodworking

Effortless Accuracy With Every Cut

The precision fence system and roller guide technology transforms challenging resaw cuts from a nerve-wracking experience into a pleasure. The COMPASS RG-2 Roller Guide utilizes independent suspension mechanism where each roller adapts to dynamic stock surfaces with consistent holding pressure. Whether you're creating book-matched panels or dimensioning exotic lumber, the fence maintains accuracy that rivals dedicated millwork machinery.

Professional Results From Day One

Harvey bandsaws arrive precisely calibrated and ready for immediate use. The factory alignment process ensures the blade guides, table, and fence are perfectly set up, eliminating the setup headaches common with other brands. The tool-less blade guide system allows instant adjustments for different blade widths, while the quick-release tension system provides consistent blade tension across all cutting applications.

Built For Demanding Use

Professional woodworking often means long sessions with challenging materials. Harvey's robust 3HP motor systems maintain consistent power through dense hardwoods and exotic species, while the precision-balanced flywheels minimize the fatigue-inducing vibration common in lesser saws. The foot brake with micro-switch provides instant stopping power for enhanced safety during extended use.

Investment-Grade Durability

The nickel-plated surfaces and precision-machined components ensure these saws maintain their accuracy for decades. Unlike painted surfaces that eventually chip and rust, Harvey's stain-less technology provides protection that becomes more valuable over time, especially in humid shop environments.

Tips For Maximizing Your Harvey Bandsaw Performance

Professional woodworkers understand that even the finest tools require proper setup and maintenance to deliver their full potential. Harvey bandsaws are designed for longevity and consistency, but following these practices will ensure optimal performance:

Proper Initial Setup

While Harvey bandsaws arrive precisely calibrated, taking time to verify blade tracking and guide alignment in your specific shop conditions ensures optimal performance. Check that the blade tracks properly on the crown of the wheels and that the guides are properly adjusted for your preferred blade width. The precision-machined components make these adjustments simple and stable.

Maintenance For Longevity

The nickel-plated surfaces require minimal maintenance—simply keep them clean and occasionally apply a light coat of paste wax for maximum smoothness. The sealed ball bearings in the blade guide system are lubricated for life, but keeping the guides clean and properly adjusted ensures continued smooth operation and extended blade life.

Blade Selection Strategy

While Harvey saws accommodate any quality blade, having dedicated blades for different operations optimizes performance. A 3/4" blade for resawing, 1/2" for general cutting, and 1/4" for detailed work covers most applications. Harvey's precision tracking system ensures consistent performance across all blade widths.

Dust Collection Optimization

Harvey Woodworking's enclosed dust collection system works best with adequate airflow. A quality dust collector connected to the lower port, combined with proper blade selection, captures the majority of dust at the source, keeping your workspace clean and extending the life of your saw's components.

Accessory Integration

Harvey Woodworking's modular approach means accessories like extended fences, mobile bases, and auxiliary tables integrate seamlessly with your saw. Planning your accessory additions allows you to create a comprehensive resawing station tailored to your specific work.

Frequently Asked Questions

Can Harvey bandsaws handle professional production work?

Absolutely. Harvey's bandsaw series are engineered for continuous professional use, with robust 3HP motors, precision components, and industrial-grade construction that maintains accuracy through demanding production schedules and heavy resaw operations.

How does the Stain-less technology compare to traditional cast iron tables?

Harvey's nickel-plating process creates a surface 500-700 HV harder than cast iron while providing complete rust resistance. The process bonds nickel deeply to the base material rather than simply coating it, creating a surface that stays smooth indefinitely and requires virtually no maintenance.

What makes Harvey's blade guide system different from standard guides?

Harvey's tool-less blade guide system uses precision ball bearings on three sides of the blade, eliminating the setup and adjustment hassles of traditional guides. The system accommodates different blade widths instantly while maintaining perfect tracking and eliminating blade drift.

Are Harvey bandsaws suitable for small workshops?

Yes, Harvey offers the AMBASSADOR C14Pro specifically designed for smaller spaces without compromising professional capabilities. The 14" resaw capacity and compact footprint provide full professional features while fitting in space-conscious workshops.

How do Harvey bandsaws integrate with existing shop setups?

Harvey bandsaws are designed with standard dust collection ports and accessory compatibility in mind. The modular approach allows integration with existing dust collection systems, mobile bases, and workflow patterns while providing upgrade paths as your shop evolves.