For many woodworkers, rust on bandsaws has long been a source of frustration. About ten years ago, Harvey began addressing this challenge by incorporating the TiN PVD Coating technology into products, reducing wear and rust on table saw surfaces.

However, Harvey is always striving for perfection. Five years ago, we started exploring the nickel plating technology.

After countless tests on the process and formulation, we have successfully implemented optimal nickel plating technology on the tabletop, the cast iron flywheel and the Worm Gear Tilting System within the bandsaws, ensuring a literally rust-free experience for users by completely eliminating issues of wear and rust.

This superior nickel plating solution adopts the autocatalytic plating process, combining with a mid-phosphorus chemical nickel formula, significantly enhances wear resistance and rust prevention capabilities, resulting in a smoother and more lustrous finish.

Furthermore, the nickel-plated table surfaces achieved an impressive hardness of 500HV - 700HV, considerably improving their wear resistance. Extensive friction tests using wooden blocks consistently demonstrated that the nickel layer effectively protected the table surface.

We conducted a series of high-temperature and strong acid corrosion tests to evaluate the longevity of the nickel-plated surfaces. The results indicated that, under normal usage conditions, the nickel-plated surfaces could maintain their rust prevention performance for years. Notably, even in highly humid working environments, they exhibited exceptional rust prevention capabilities.

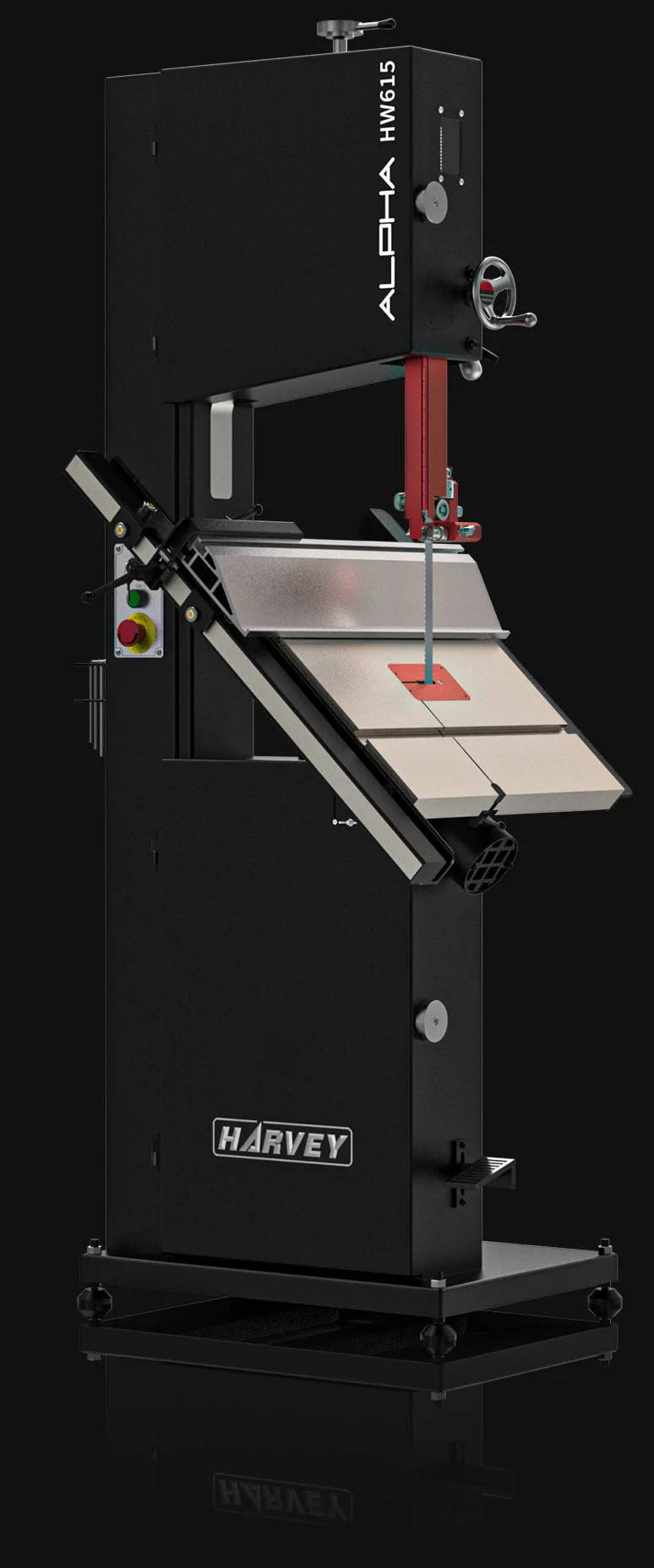

We are confident that the Alpha HW615Pro Stain-less Bandsaw represents the ultimate solution to the rust problem in bandsaws. Guided by our steadfast philosophy that "Good Enough is Not Enough," this bandsaw exemplifies our unwavering dedication to innovation and precision.

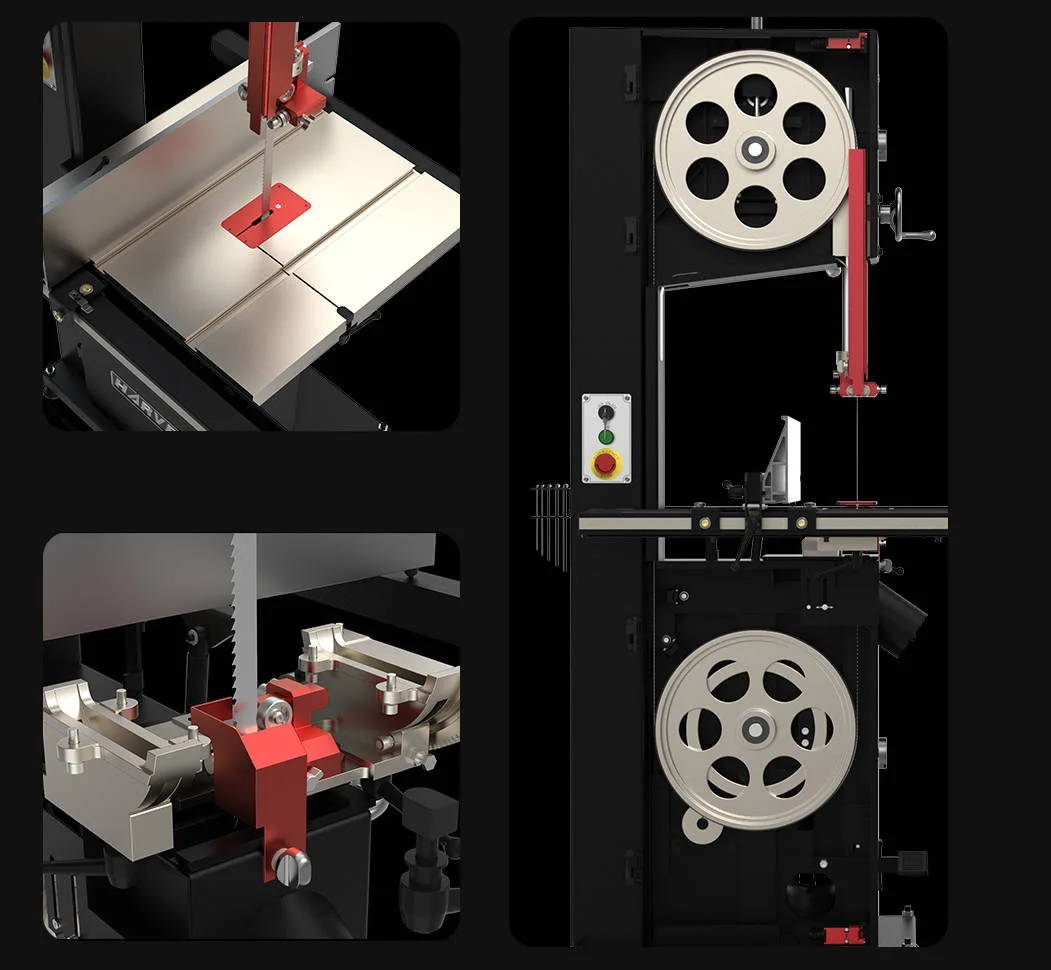

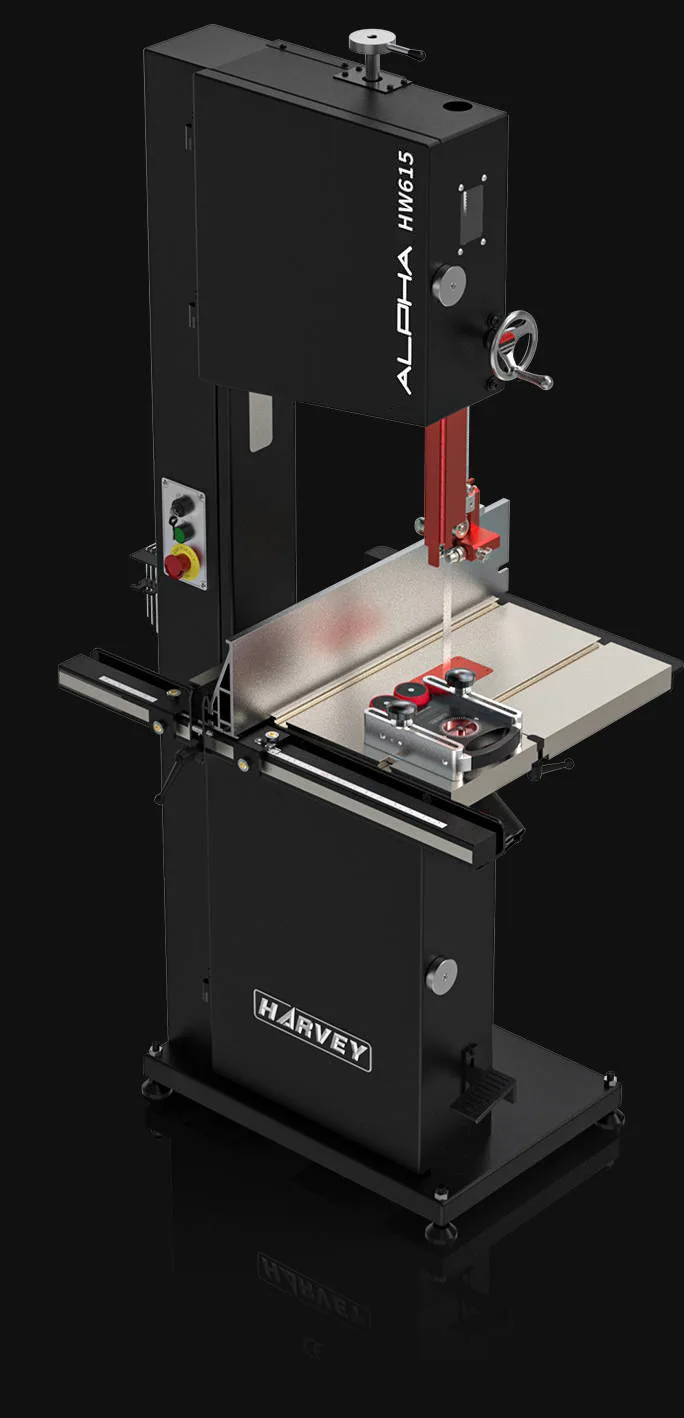

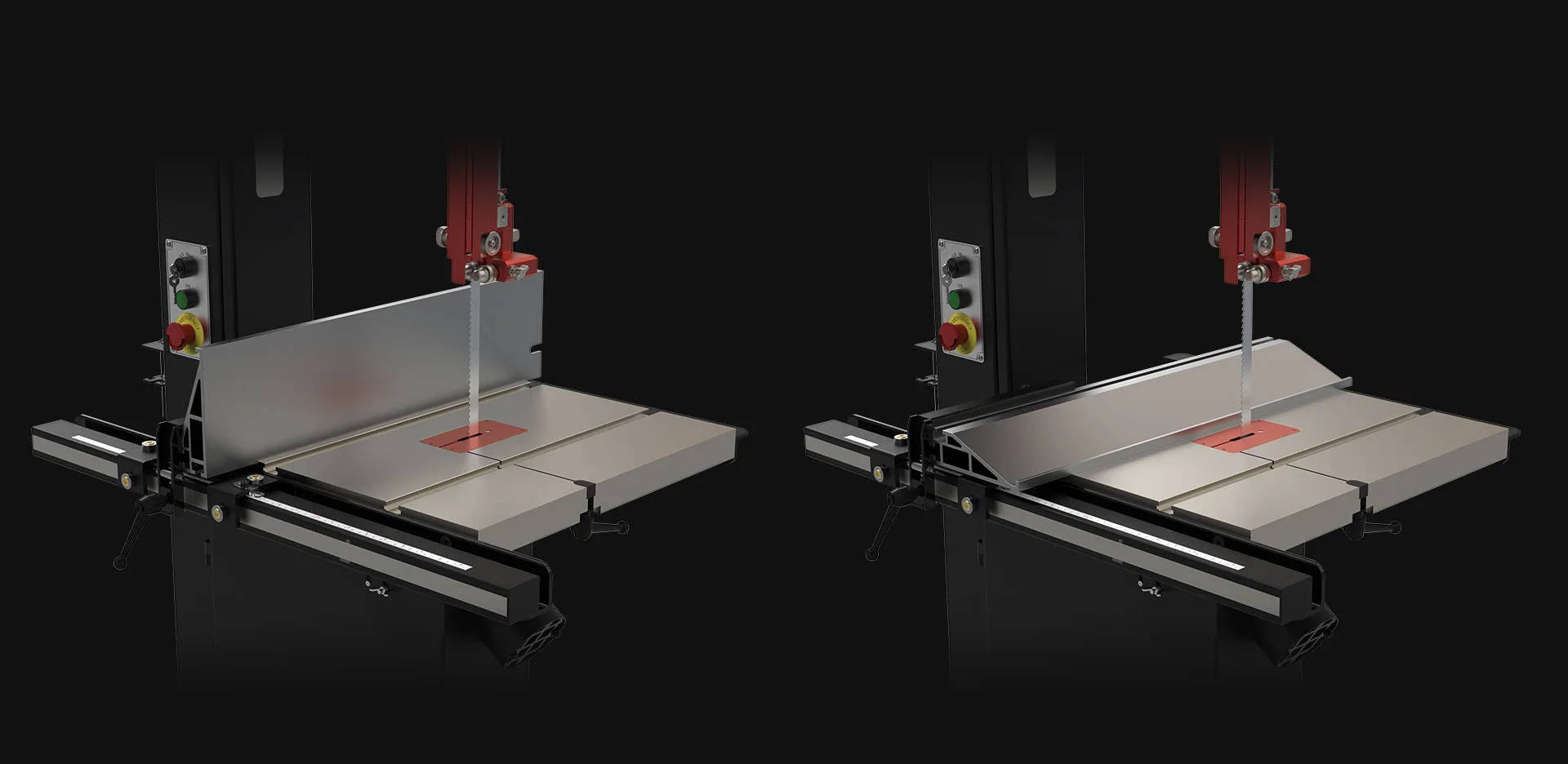

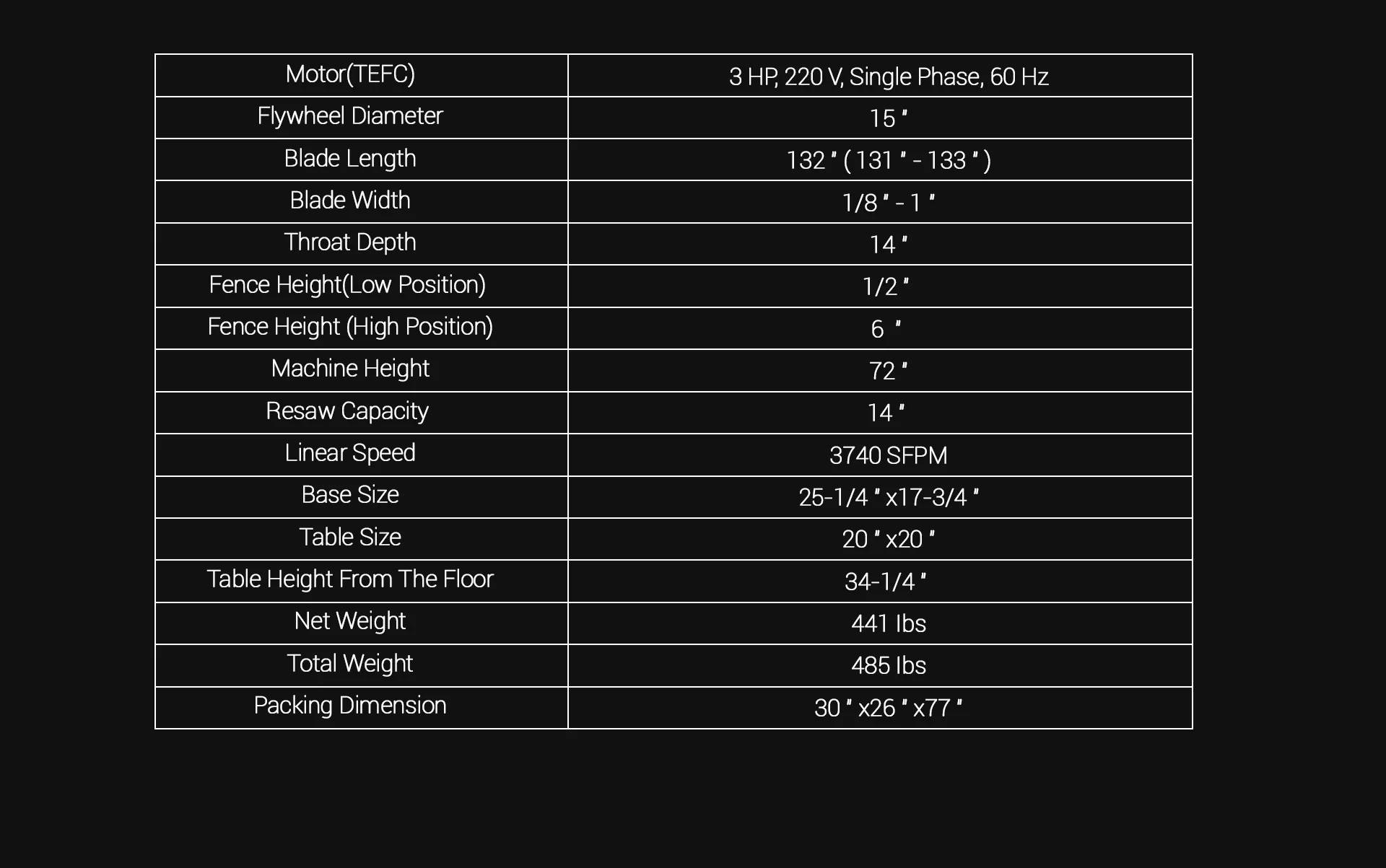

What’s more, the Alpha HW615Pro is built with a 3 HP, 220V motor to ensure enough power to undertake any job that a 15" bandsaw can handle. It features a solid, reinforced structural steel frame; premium, heavy-duty cast iron flywheels; unique tool-less upper and lower blade guides; the newly developed COMPASS RG-2 Roller Guide for safe and enjoyable cutting; a substantial 20" x 20" work table; an extra-large precision high-low aluminum fence with a solid T-square gliding/locking structure; a worm gear system for smooth work table tilt; dual trunnions for stability; and a fully enclosed blade guard.

For woodworkers seeking a bandsaw that combines traditional reliability with innovative features, the Alpha HW615Pro is the ultimate choice. Experience the next level of industrial-grade woodworking machinery with Harvey Industries.

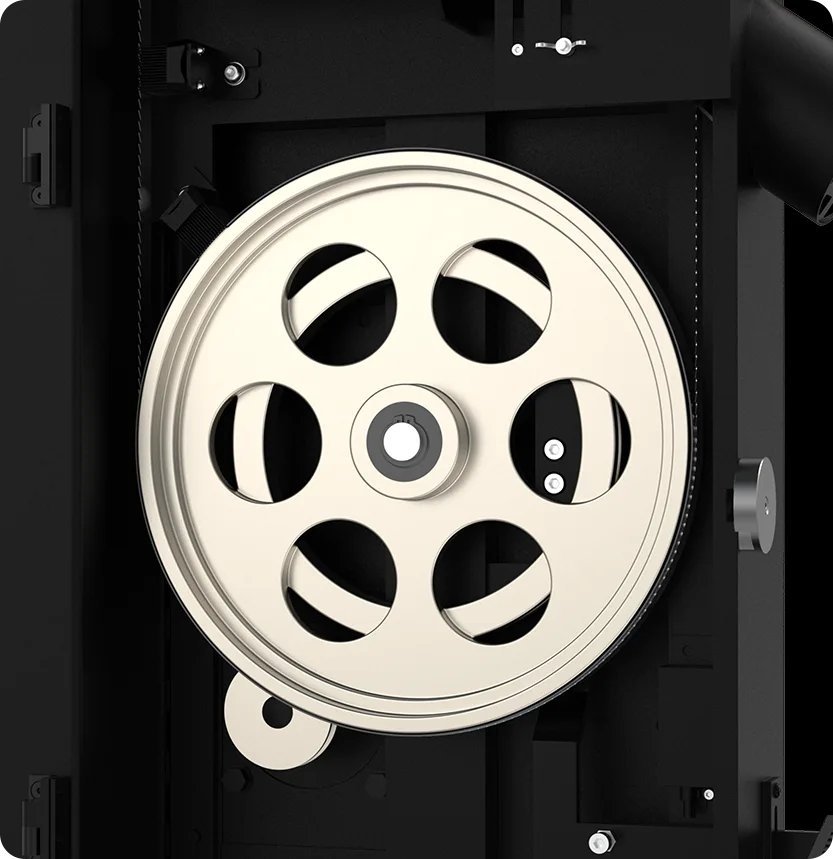

* Dynamically Balanced Cast Iron Flywheels with Nickel-Plating

* Nickel-Plated Worktable For Superior Rust and Wear Resistance

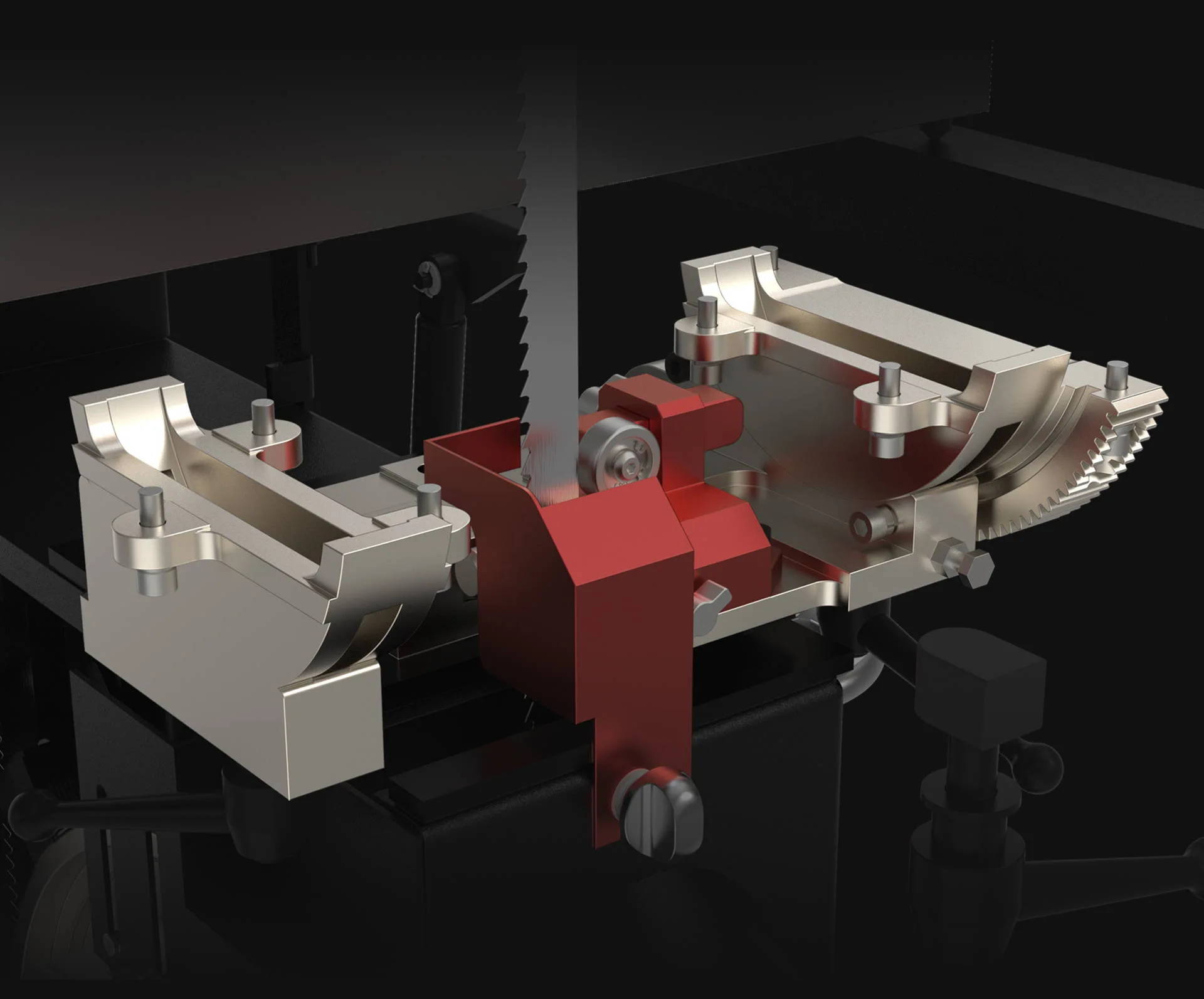

* Nickel-Plated Worm Gear Tilting System

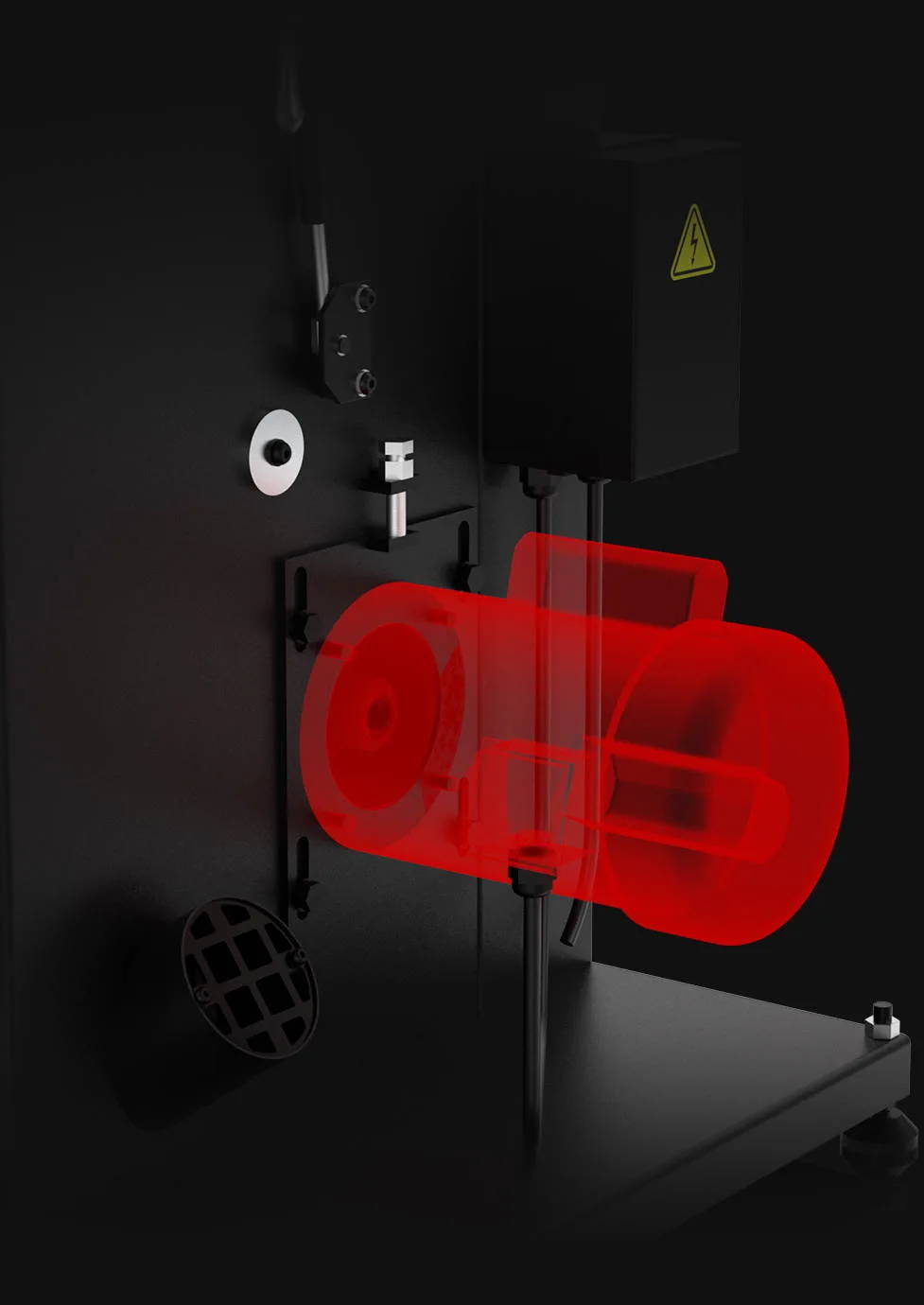

* 3HP Powerful TEFC Single Phase Motor(220V)

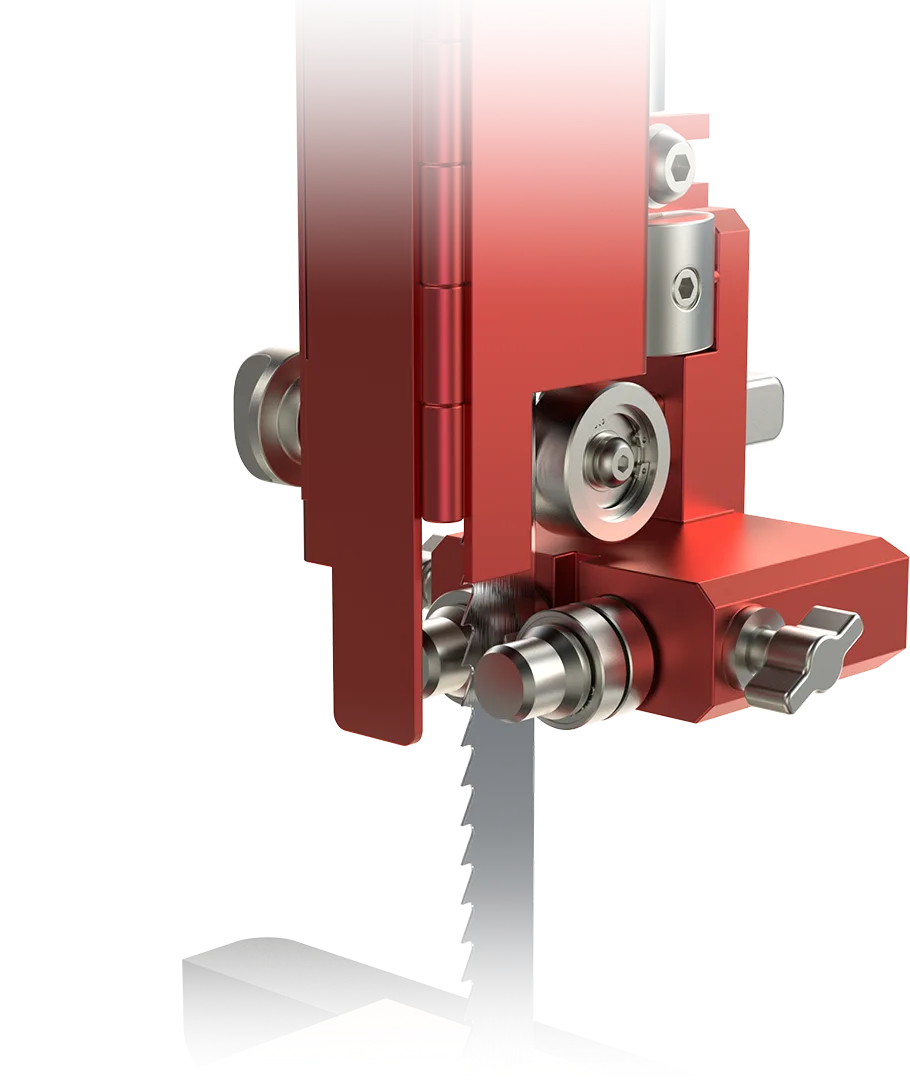

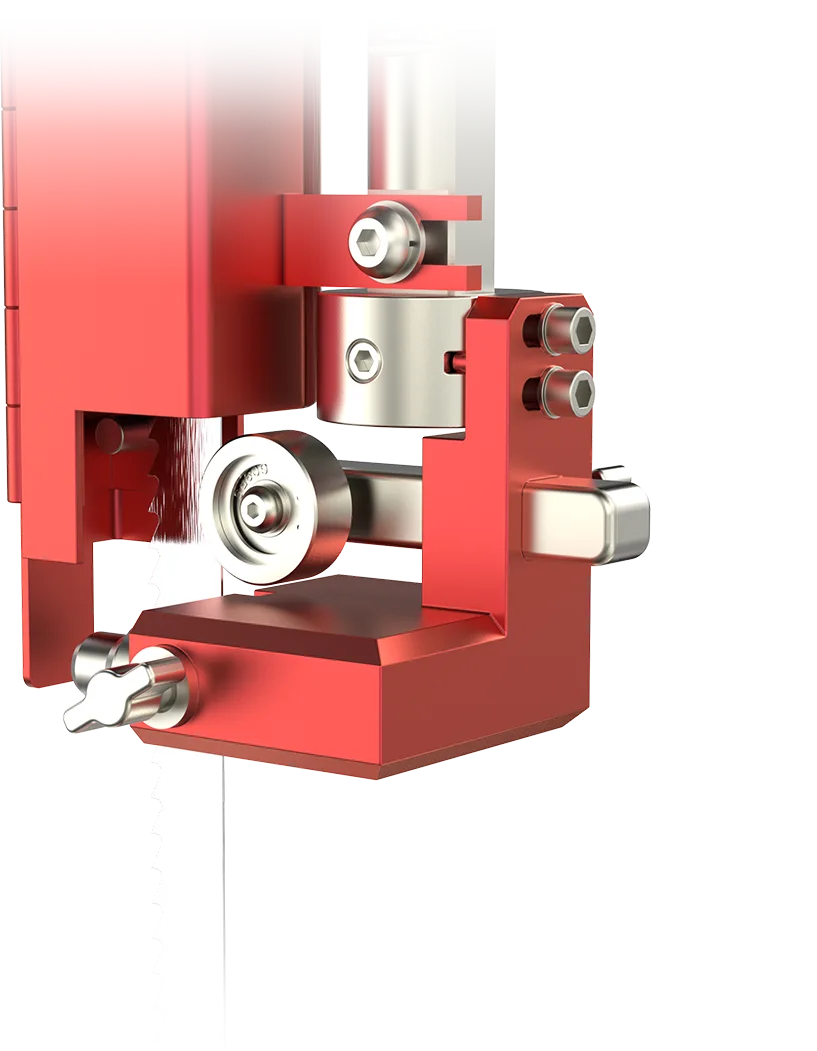

* Unique Tool-Less Upper and Lower Blade Guides

* Extra Sized and Robust Steel Frame

* Quick Release Tensioning Levers

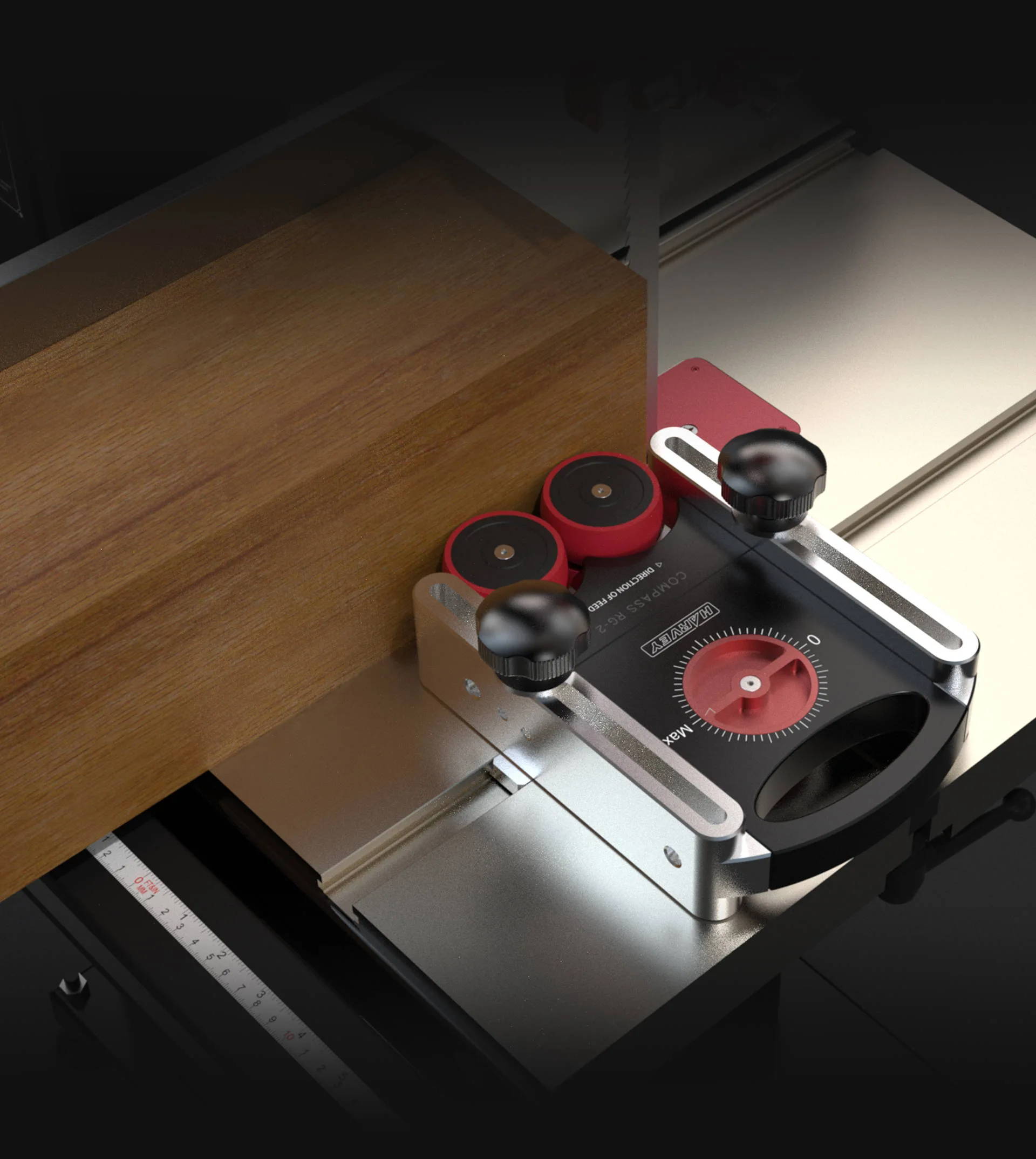

* COMPASS RG-2 Roller Guide

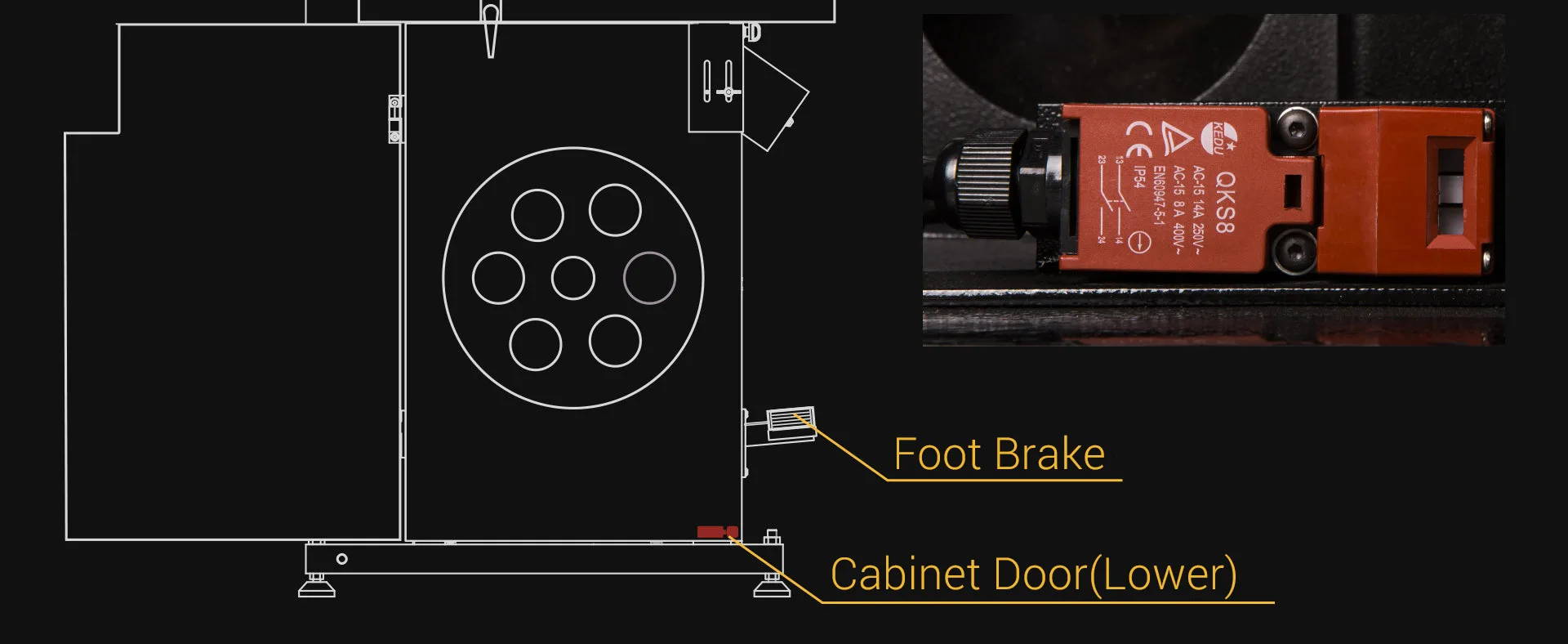

* Foot Brake with Micro Switch

* Full Enclosure Protection for Blade

* Micro-Switches On the Top and Bottom Doors

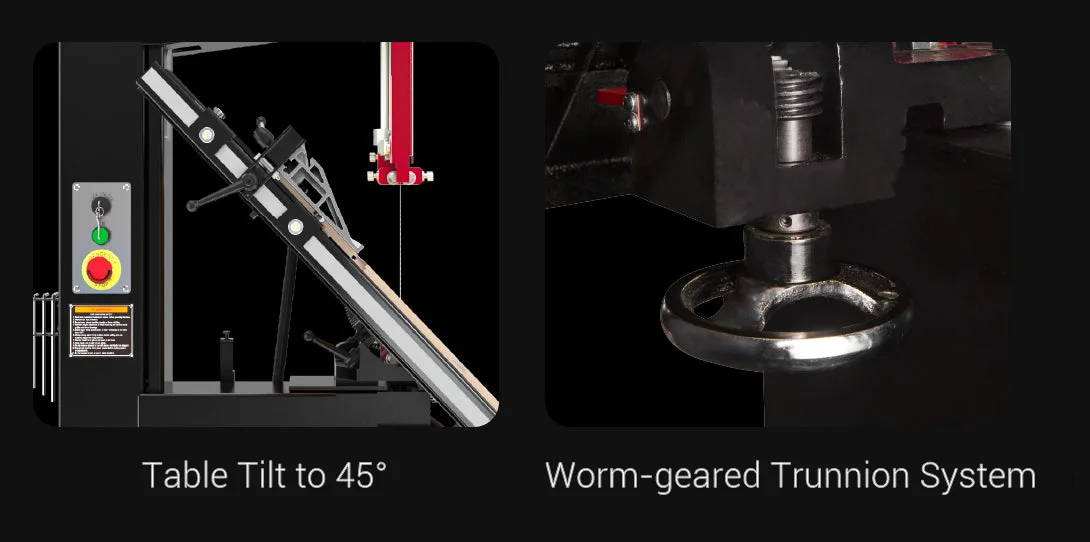

* Dual Trunnion System for Stable Support of Worktable

* Extra Large Aluminum Alloy Precision High/Low Fence

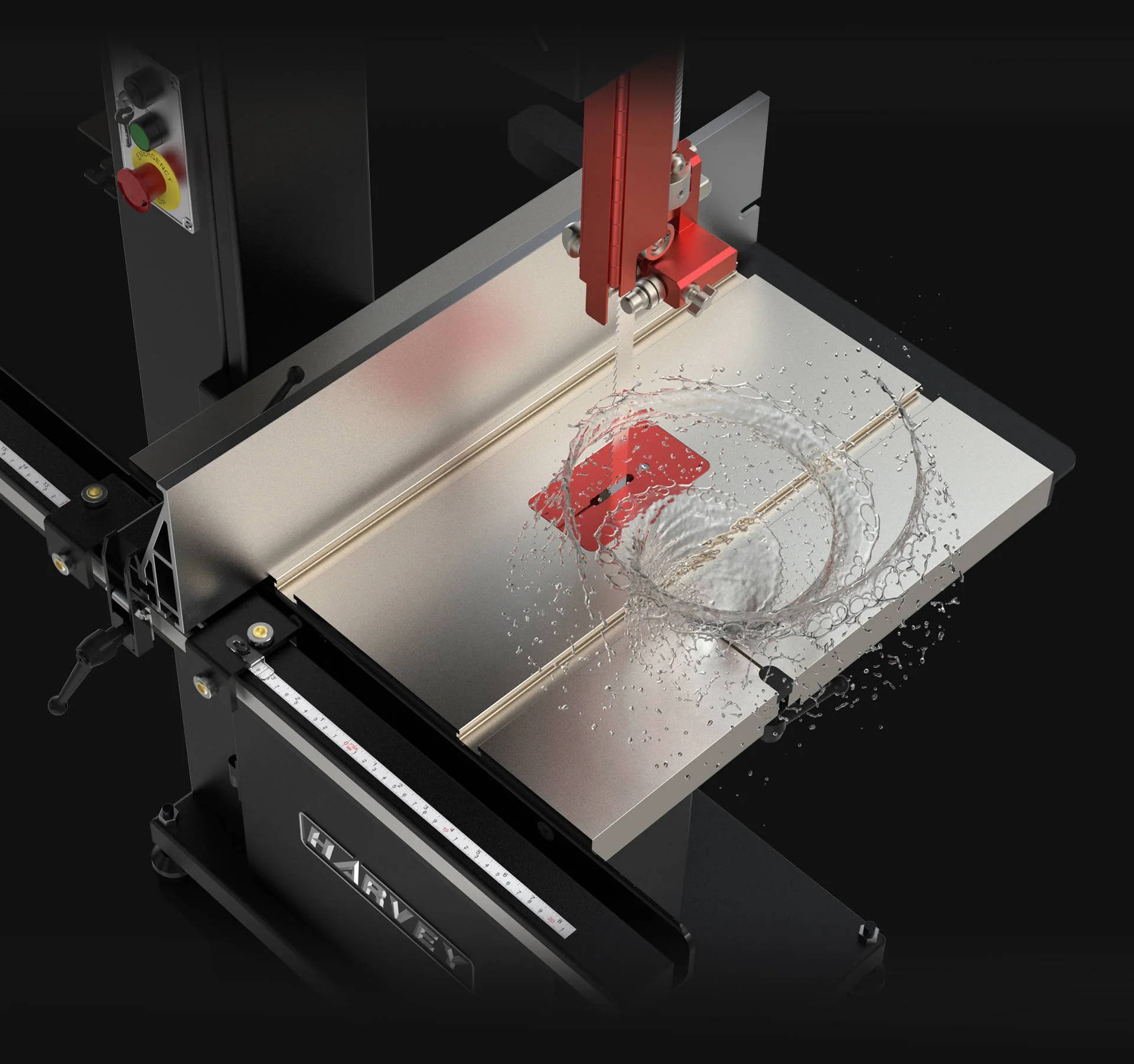

The worktable undergoes a chemical nickel-plating process that bonds the nickel layer thickly to the base material, reaching an impressive hardness range of 500 HV to 700 HV, significantly enhancing its durability and resistance to corrosion and wear. Extensive friction tests using wooden blocks consistently demonstrated that the nickel layer can effectively protected the table surface.

Additionally, we performed a series of tests involving high temperatures and strong acids to determine the longevity of the nickel-plated surfaces. The results showed that, under normal conditions, the nickel-plated surfaces could retain their rust-preventive properties for many years. Impressively, they also exhibited excellent rust prevention in highly humid work environments.

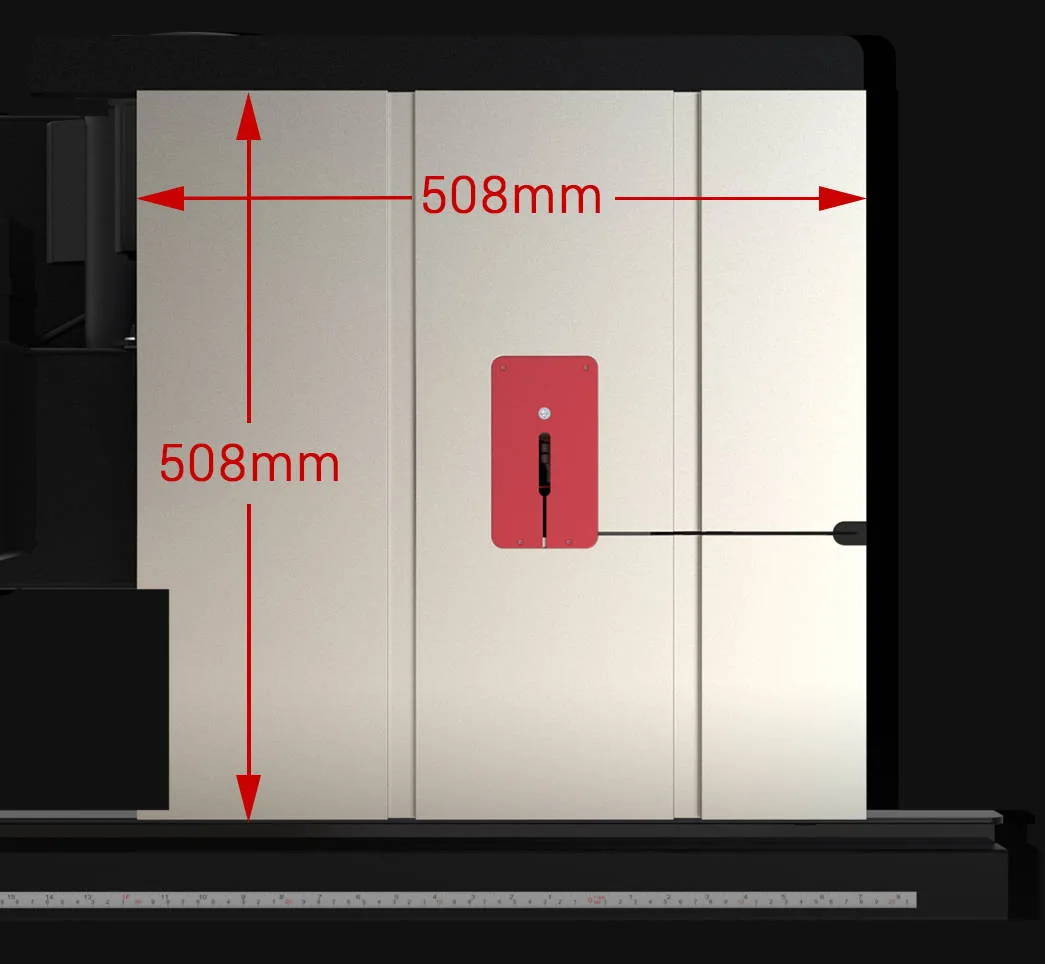

A substantial 20" x 20" (508x508 mm) cast iron table offers a sturdy and expansive work area, treated with nickel-plating to resist rust and wear, ensuring exceptional resistance to rust and wear, which markedly extends its service life.

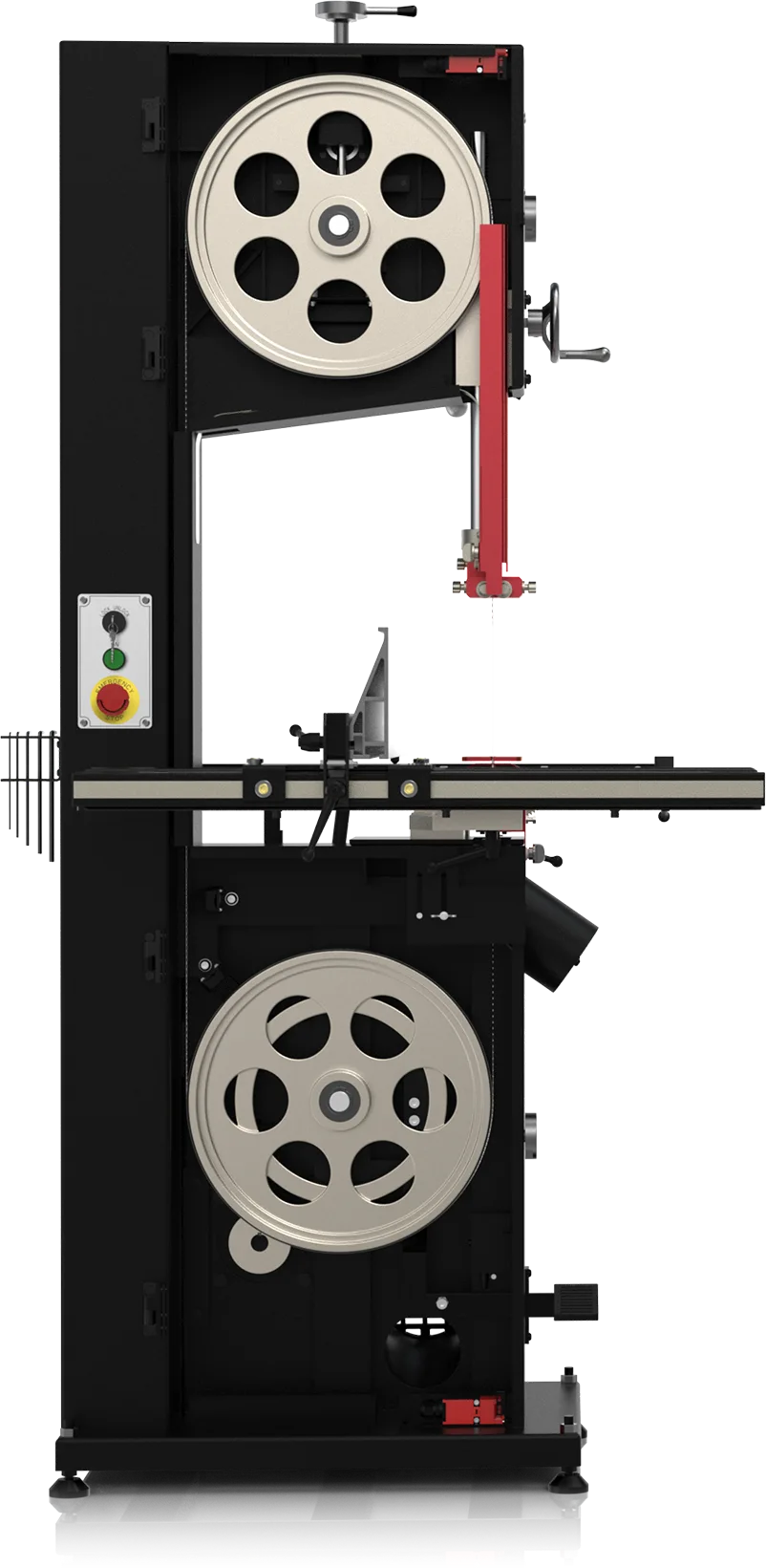

The nickel-plated Flywheels offer superior resistance to rust and wear, significantly extending their service life.

We performed a series of tests involving high temperatures and strong acids to determine the longevity of the nickel-plated surfaces. The results showed that, under normal conditions, the nickel-plated surfaces could retain their rust-preventive properties for many years. Impressively, they also exhibited excellent rust prevention in highly humid work environments. This ensures rust resistance and longevity, making the flywheels maintenance-free for rust prevention.

Dynamically balanced cast iron flywheels ensure smooth operation, minimal noise, and superior momentum for consistent cutting.

The reinforced solid steel frame provides remarkable rigidity and stability, enhancing durability and performance under the most demanding conditions.

The nickel plating of the entire Worm Gear Tilting System offers enhanced resistance to corrosion and wear, making the HW615Pro virtually maintenance-free for rust prevention.

We carried out a series of high-temperature and strong acid corrosion tests to assess the durability of the nickel-plated components. The findings revealed that, under typical usage conditions, the nickel-plated surfaces could sustain their rust prevention performance for years. Remarkably, even in extremely humid working environments, they demonstrated outstanding rust prevention capabilities.

Tilting Table: Precisely tilt the worktable from 45 degrees to -15 degrees using a robust worm-gear system with a heavy-duty handwheel. Gas pistons assist in micro-adjustments, making the process smooth and straightforward.

In order to enhance the operation safety and user experience of the HW615Pro, our newly developed COMPASS RG-2 Roller Guide is included as standard accessory. The main body of RG-2 is made of anodized aircraft-grade aluminum with high precision machining and beautiful anodizing.

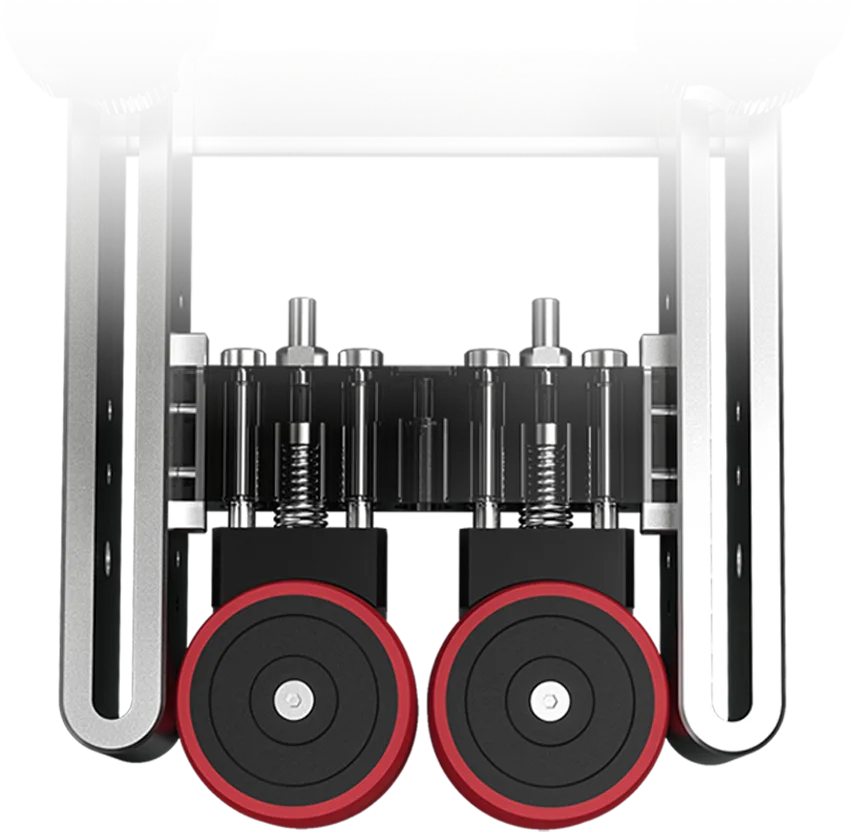

The Compass RG-2 Roller Guide utilizes an 'Independent Suspension Mechanism' where each roller has its own pre-loaded spring. This design enables the two guide rollers to adapt to dynamic stock surfaces with consistent holding pressure by moving independently.

The Self-locking Cam Structure allows for precise holding force adjustment by rotating the knob to optimize pressure for specific cutting situations. It offers an adjustable range of approximately15 – 22 lbs (70 – 100 N), suitable for various cutting scenarios.

Ball Bearing Blade Guide: this patented new system incorporates a ball bearing on each side and the back of the blade, which improves the wear resistance and work life of the machine.

The tool-less adjustment and lock knobs are thoughtfully designed to provide easy access and use. Both top and bottom guide sets utilize this system.

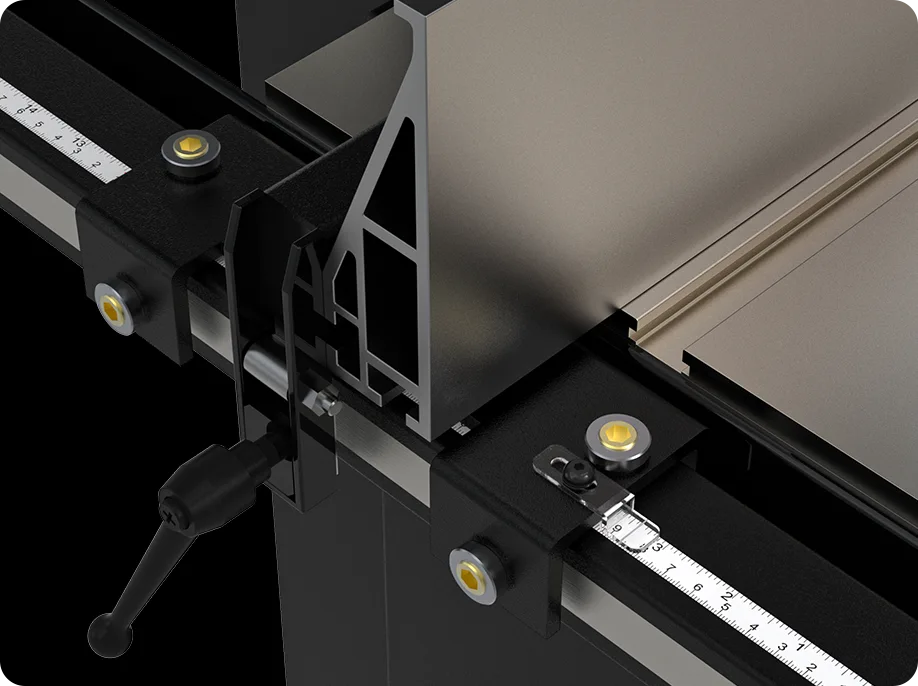

Fence: the fence has been upgraded to a extra-large precision Hi-Low fence of 6", which is made of high strength extruded aluminum. The position of the fence can be changed to accommodate the size of the work piece. In the vertical position, the fence provides stability for re-sawing applications.

Rail: the rail has been upgraded to a structural steel tube providing additional strength and rigidity and allowing for more precise settings. The solid T-square structure is easily adjustable and allows the fence to slide smoothly.

Safety Shut Offs for Both Doors: the upper and lower cabinet doors are equipped with safety switches which automatically shut off the machine when a door is opened.

Foot Brake: immediately stops the saw blade when needed.

Switch: The magnetic switch is lockable and can also prevent overheating of the motor.

Motor: the 3HP TEFC, industrial grade motor supplies robust power needed for the large capacities of this band saw.

This product is certified by the TÜV Rheinland

"Some images on this page are computer-generated representations of the product and may differ from the actual product. Colors, textures, and other details may not be accurately represented in the images. Please refer to the product description and specifications for more information."

CUSTOMER TESTIMONIALS

YOU MAY ALSO LIKE...

Explore Our Curated Selection of Accessories...

"Some images on this page are computer-generated representations of the product and may differ from the actual product. Colors, textures, and other details may not be accurately represented in the images. Please refer to the product description and specifications for more information."

Explore Our Curated Selection of Accessories...