Product Overview & Features

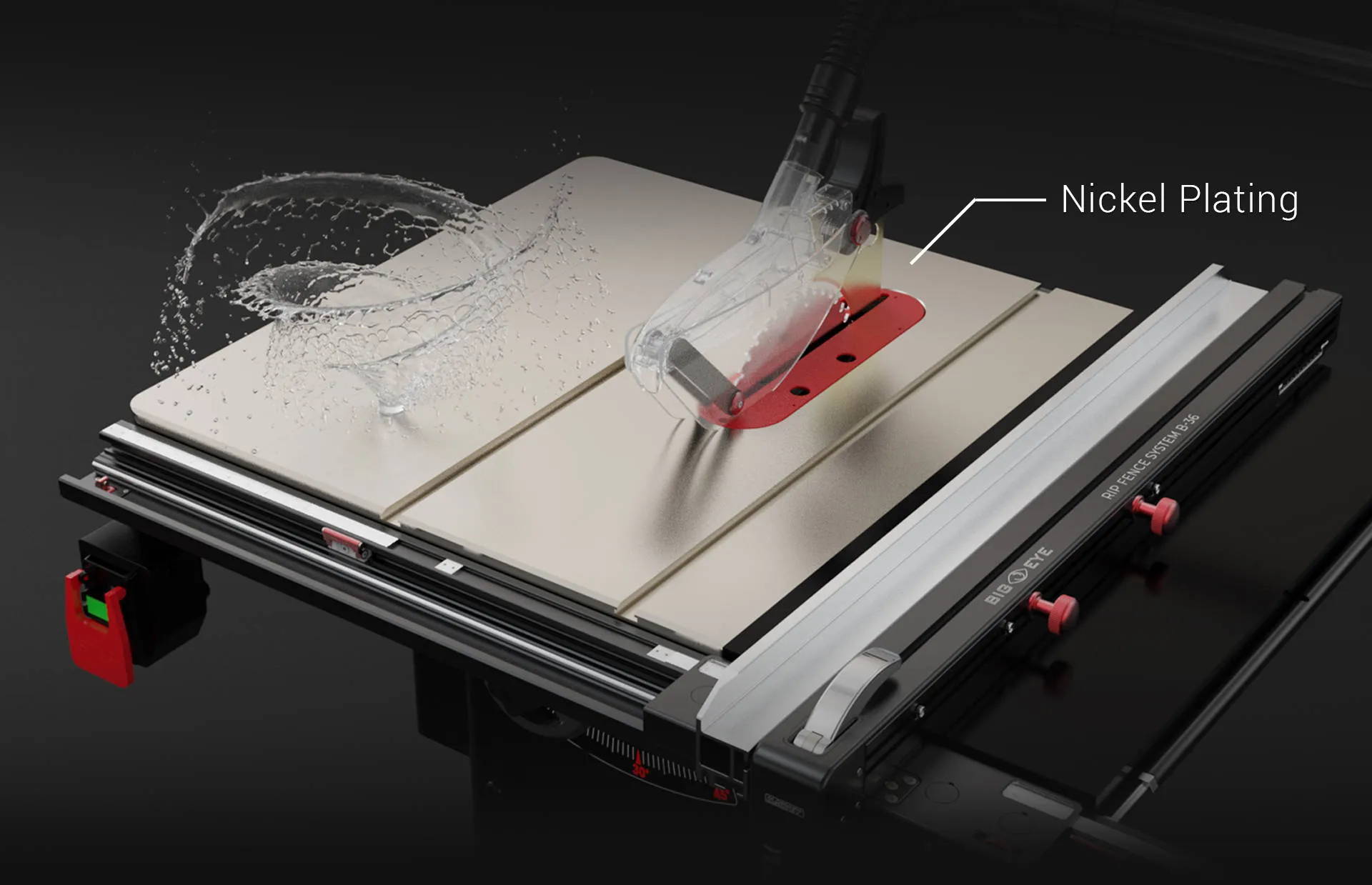

What makes the Alpha HW110LC-36Pro cabinet saw "stain-less" and how does the nickel plating work?

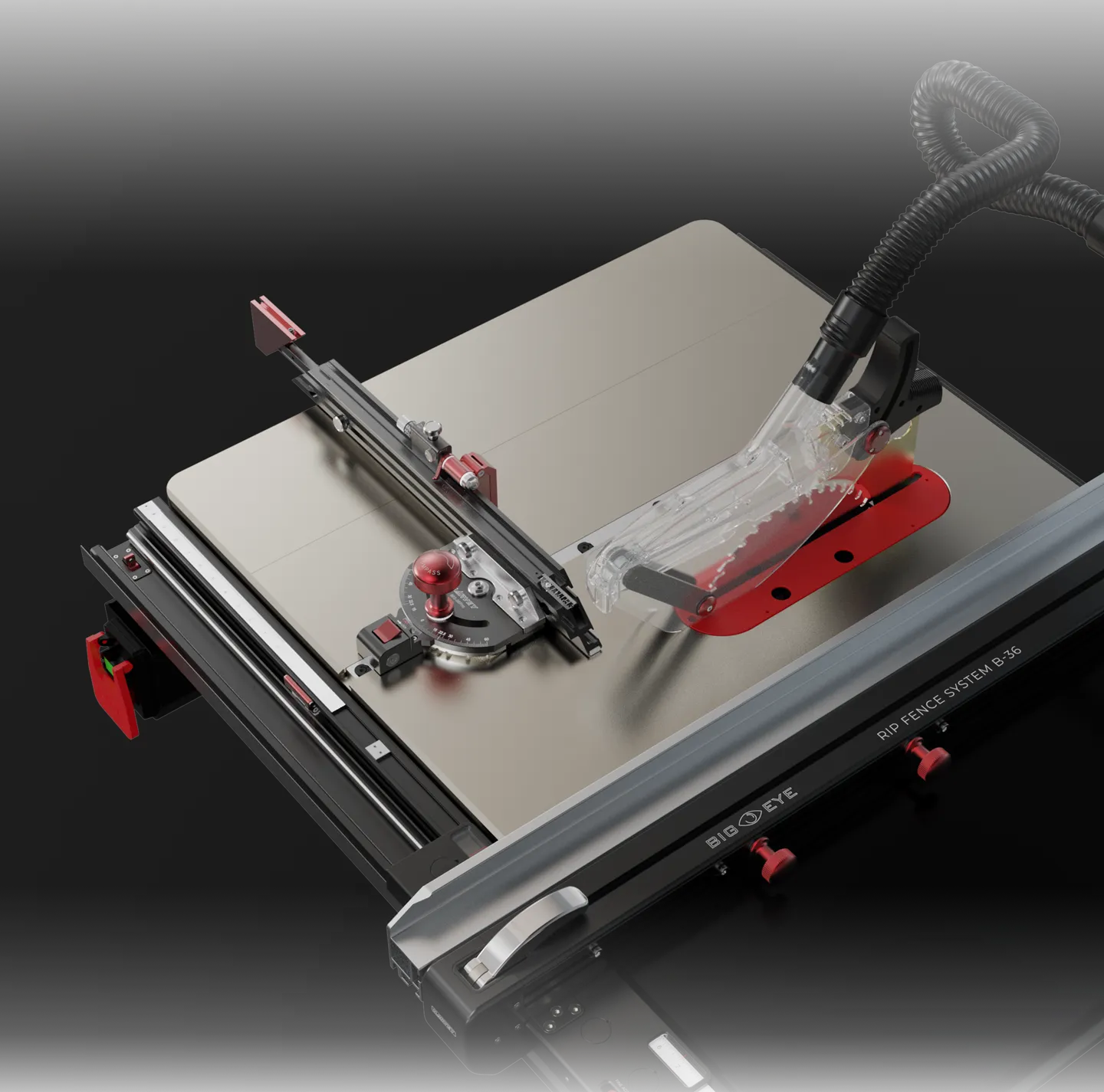

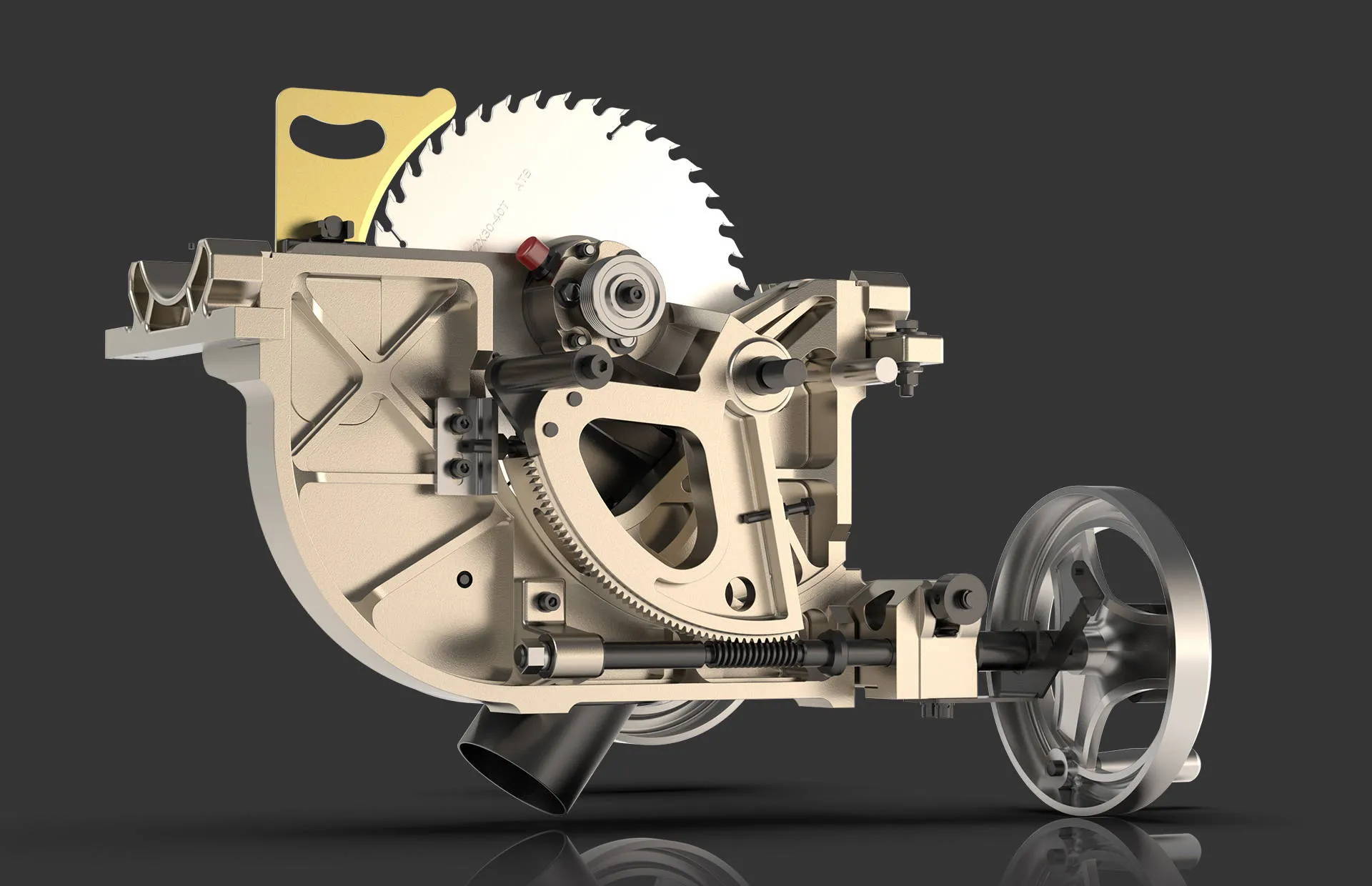

The Alpha HW110LC-36Pro features advanced nickel plating technology on the cast iron table and worm gear trunnion system. This autocatalytic plating process uses a mid-phosphorus chemical nickel formula that achieves 500-700HV hardness, providing superior rust and wear resistance. Under normal usage conditions, the nickel-plated surfaces maintain rust prevention performance for years, even in highly humid working environments.

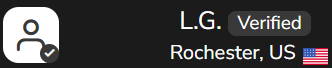

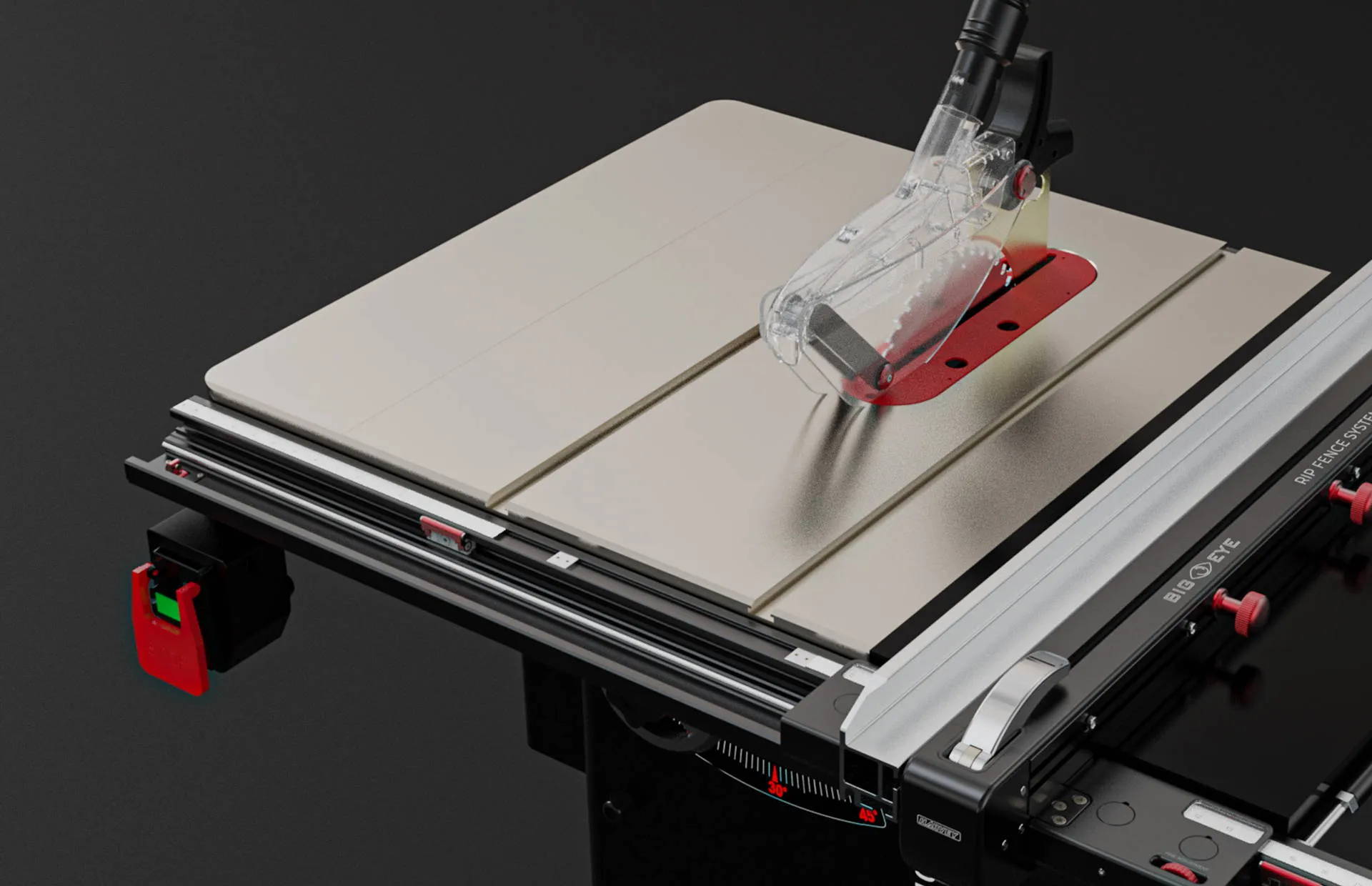

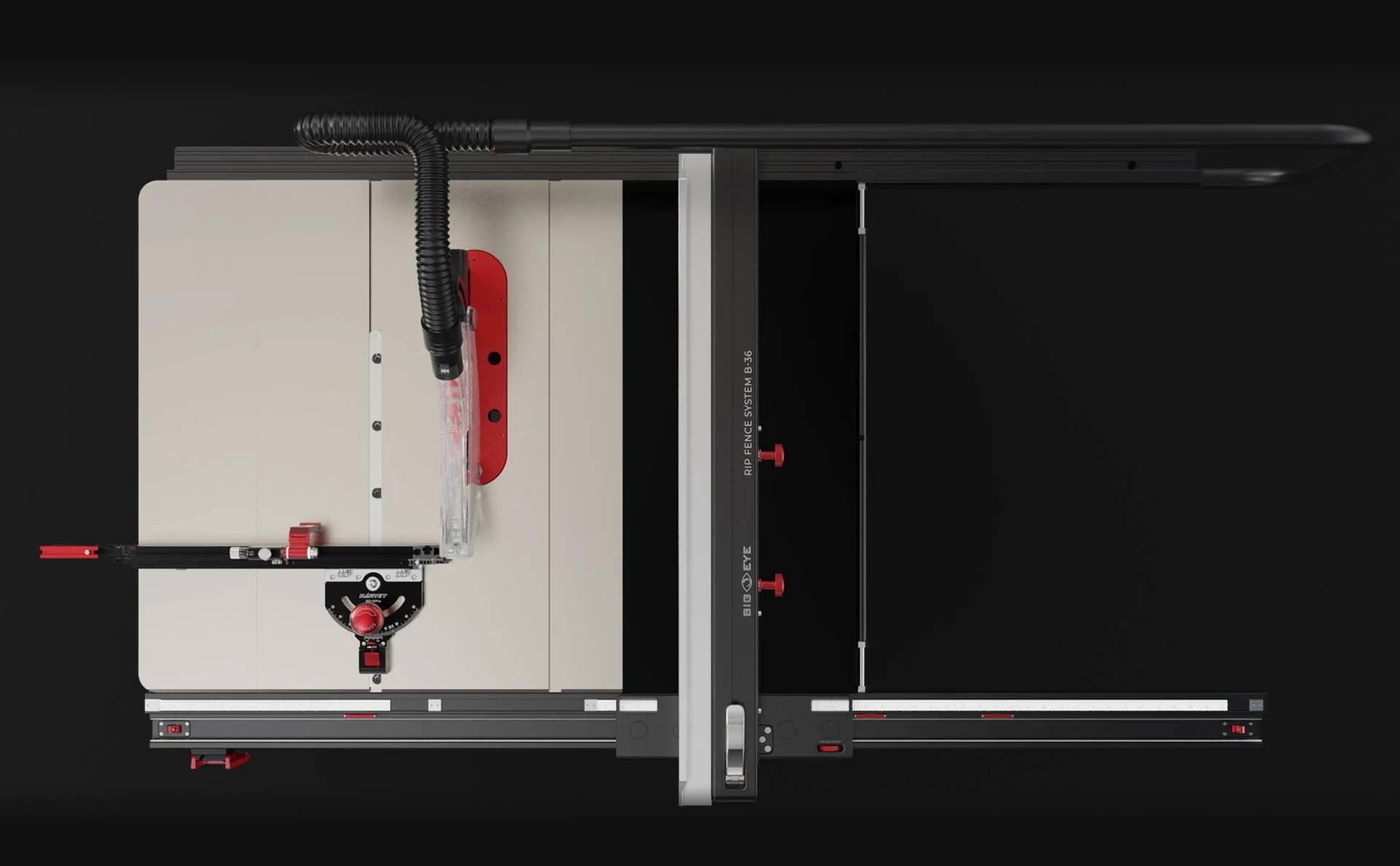

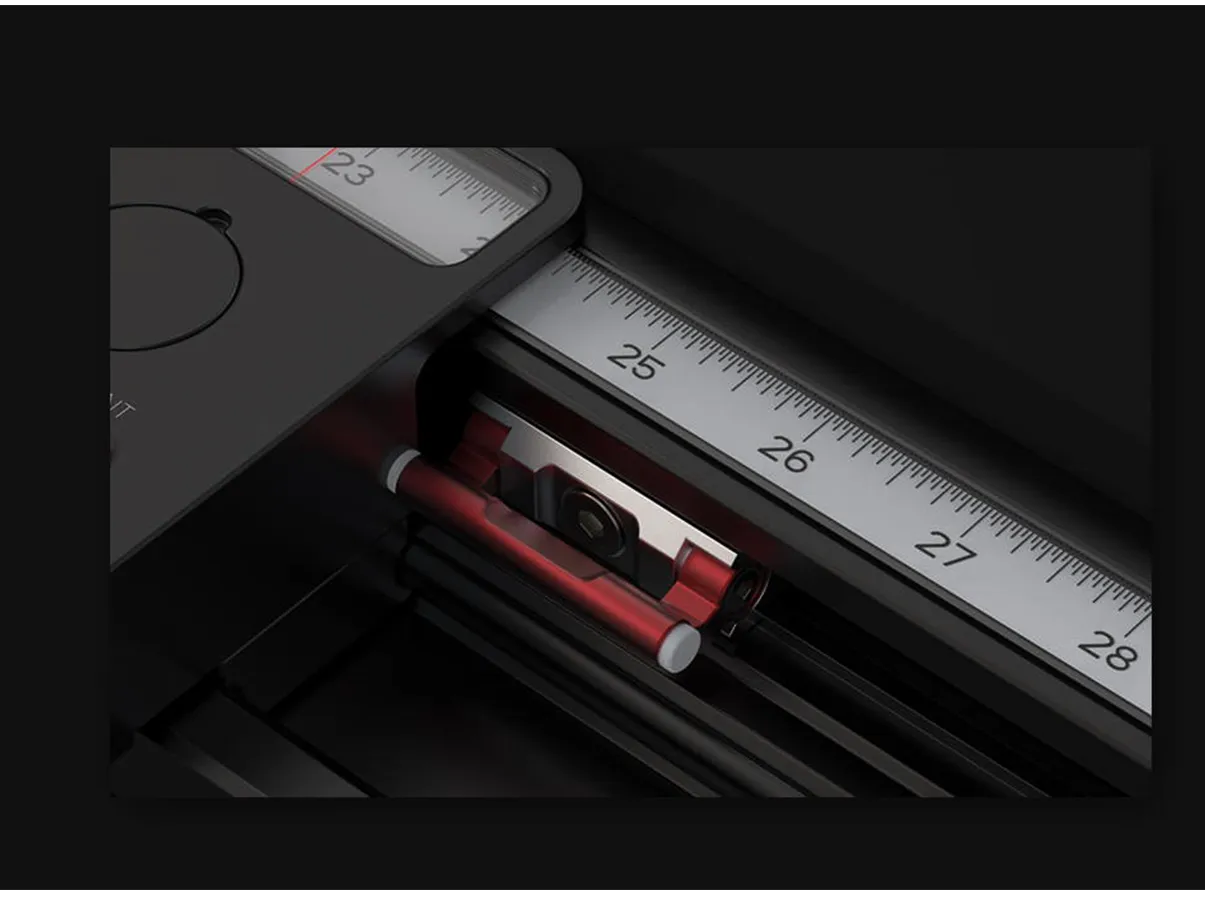

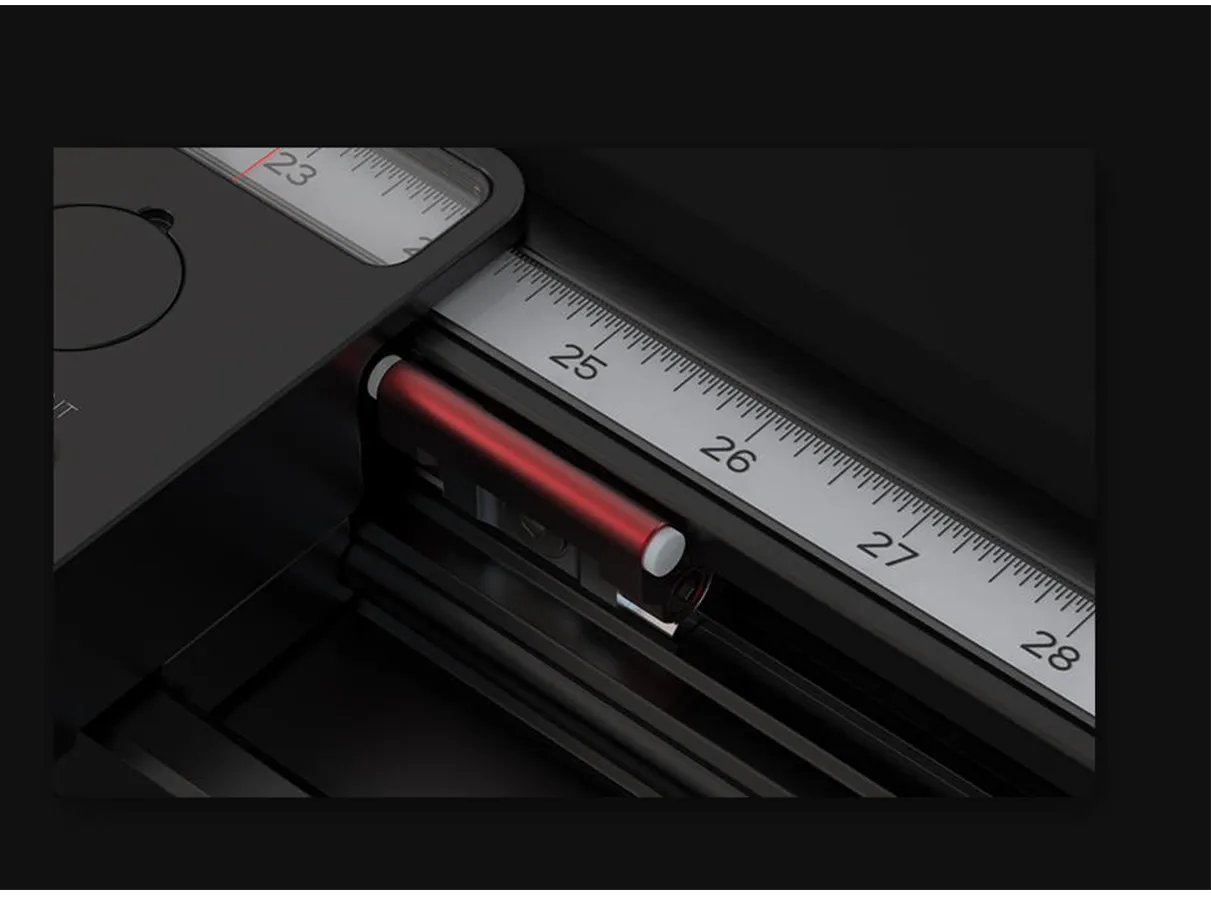

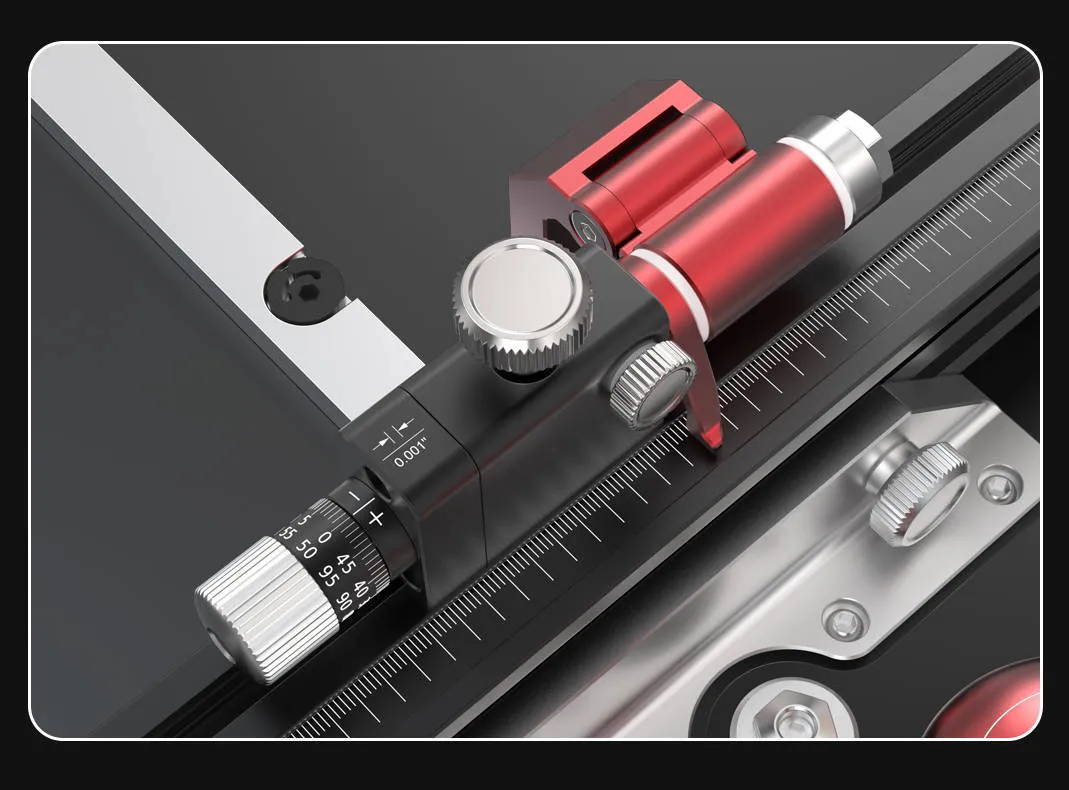

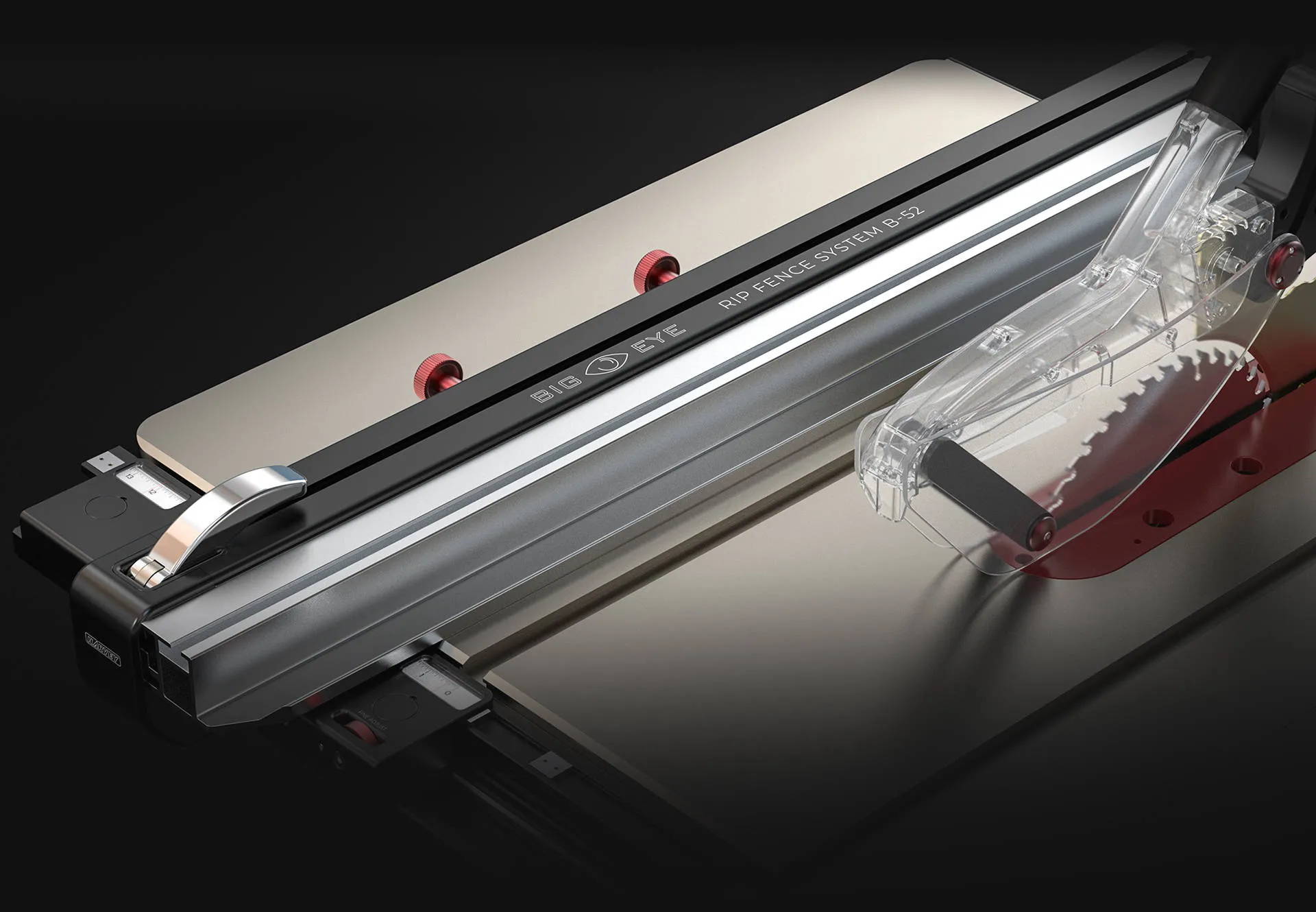

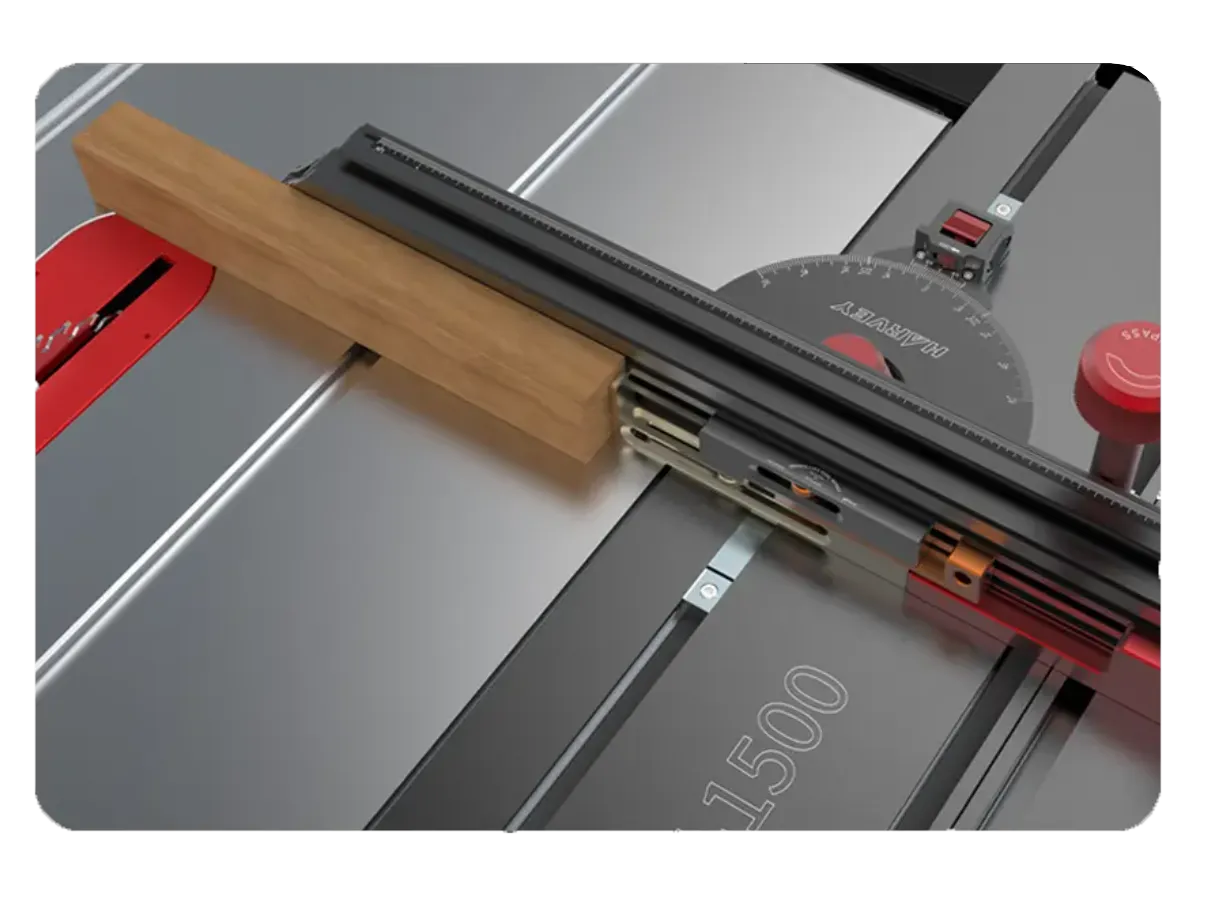

What is the Big Eye Rip Fence System and how does it improve accuracy?

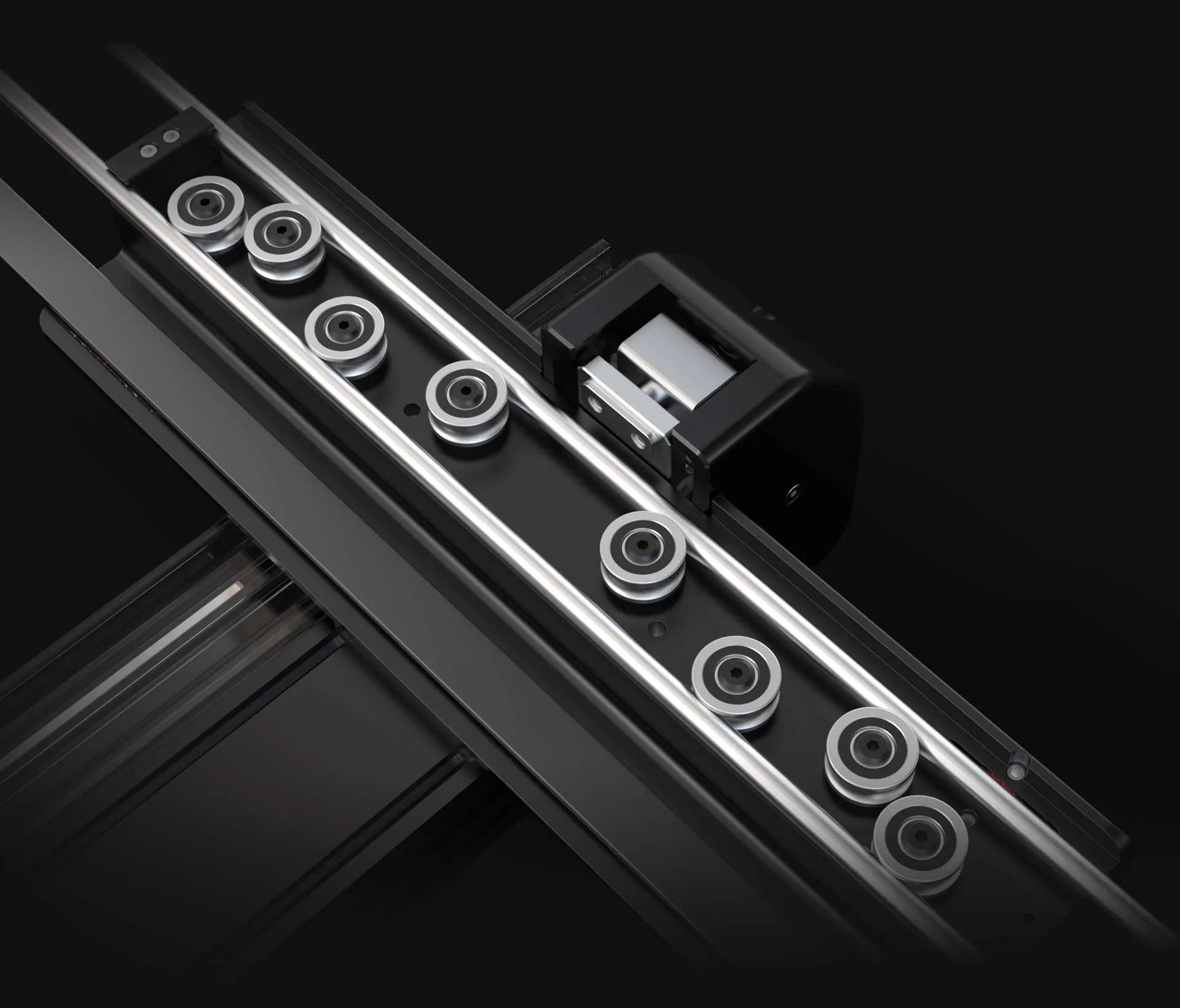

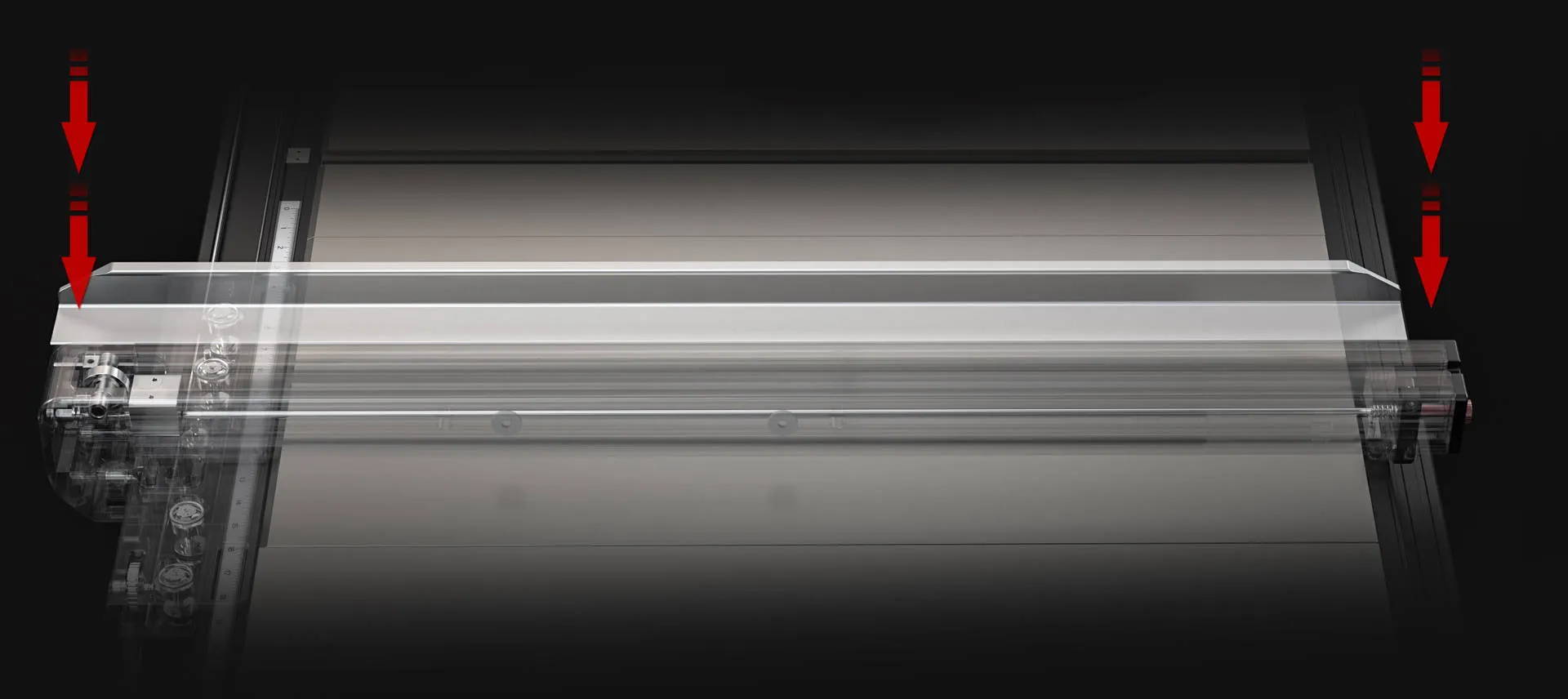

The Big Eye Rip Fence System features a dual-axis linear guide rail system with eight rollers and bearings that glide along two hardened steel rods with zero clearance. This replaces traditional bushing friction with smooth rolling friction, achieving exceptional fence movement accuracy. The synchronized dual-end fence locking mechanism enables simultaneous clamping of the fence onto the solid front and rear guide rail bodies, allowing for "single action" locking and preventing fence deflection during cutting.

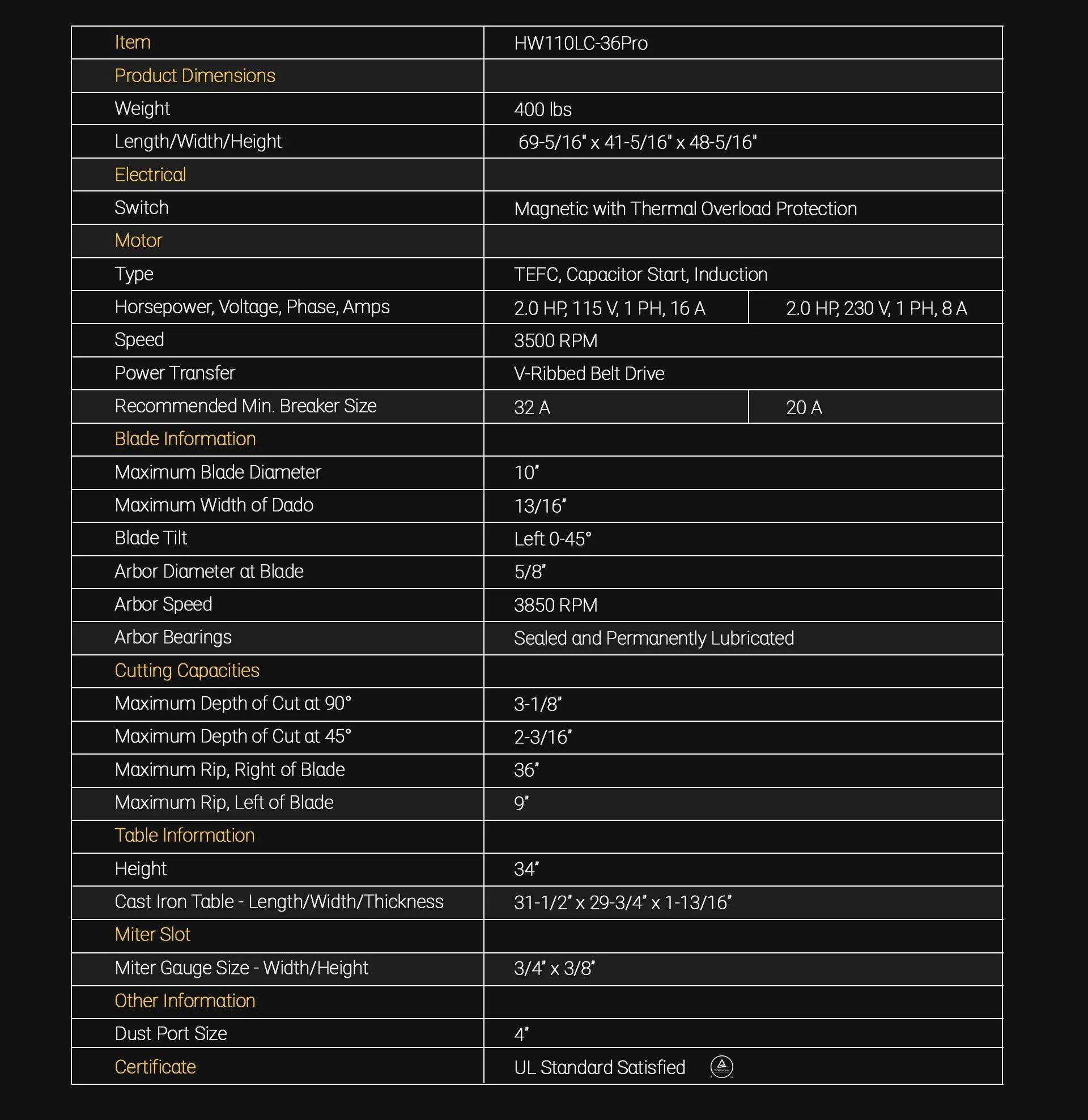

What type of power requirements does the 2HP motor need?

North American models require either 115V single-phase (16A) or 230V single-phase (8A) power, 60Hz frequency, with 20A circuit breaker and RCD module. European/Asian models require 220V single-phase (10A), 50Hz frequency, with 20A circuit breaker and RCD module. All electrical connections must be made by qualified electricians.

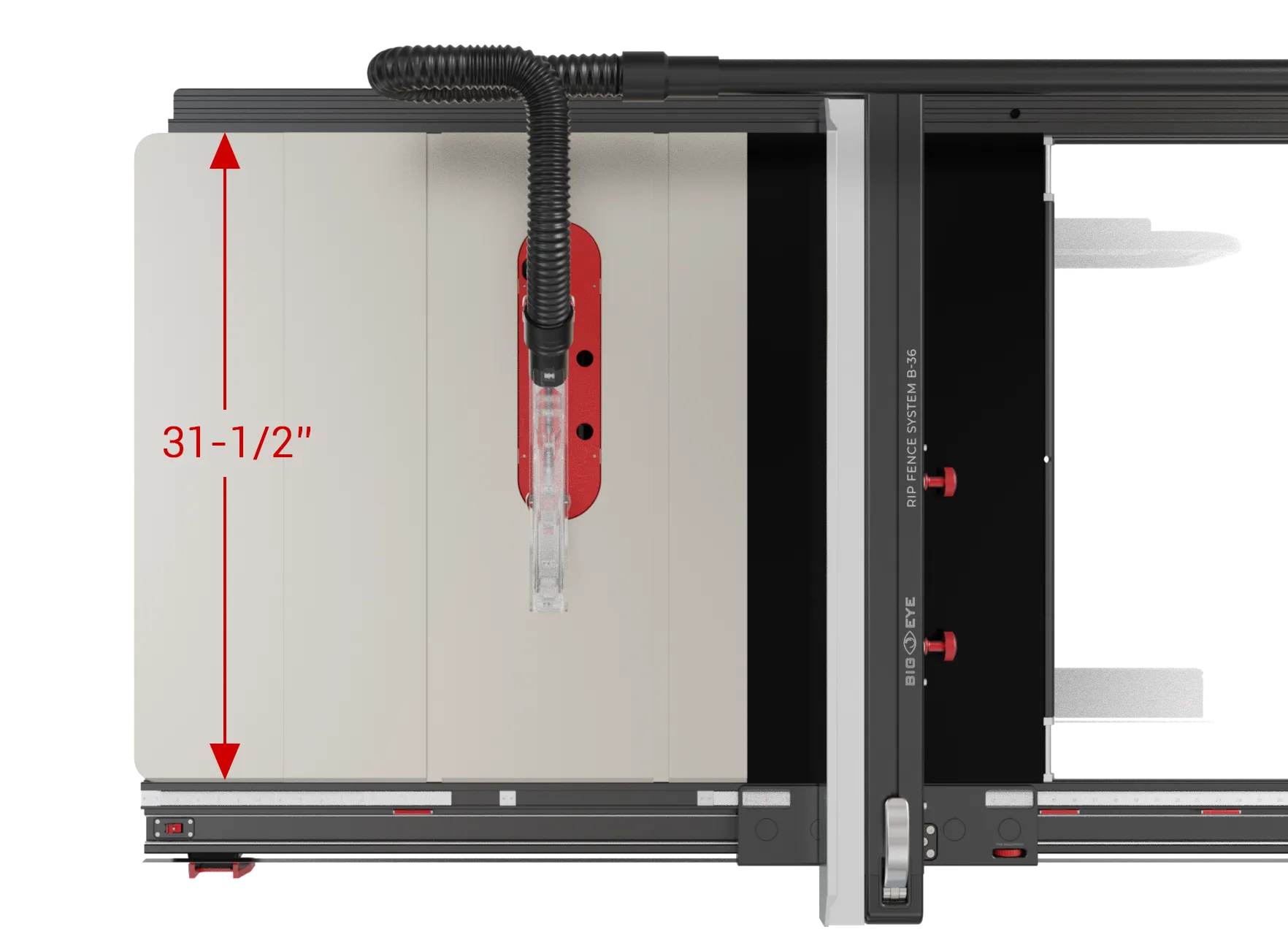

How much space do I need for this Alpha HW110LC-36Pro cabinet saw and how much does it weigh?

Total dimensions: 70-3/4" × 49-3/4" × 48-1/4" (1795×1265×1225mm). Footprint: 20-1/4" × 19-5/8" (514×498mm). Net weight is 411 lbs (186.5 kg). Table height is 34" (867mm). The cast iron table surface measures 31.49" × 22.44" × 1.83" thick with distance from front edge to blade center of 18.9".

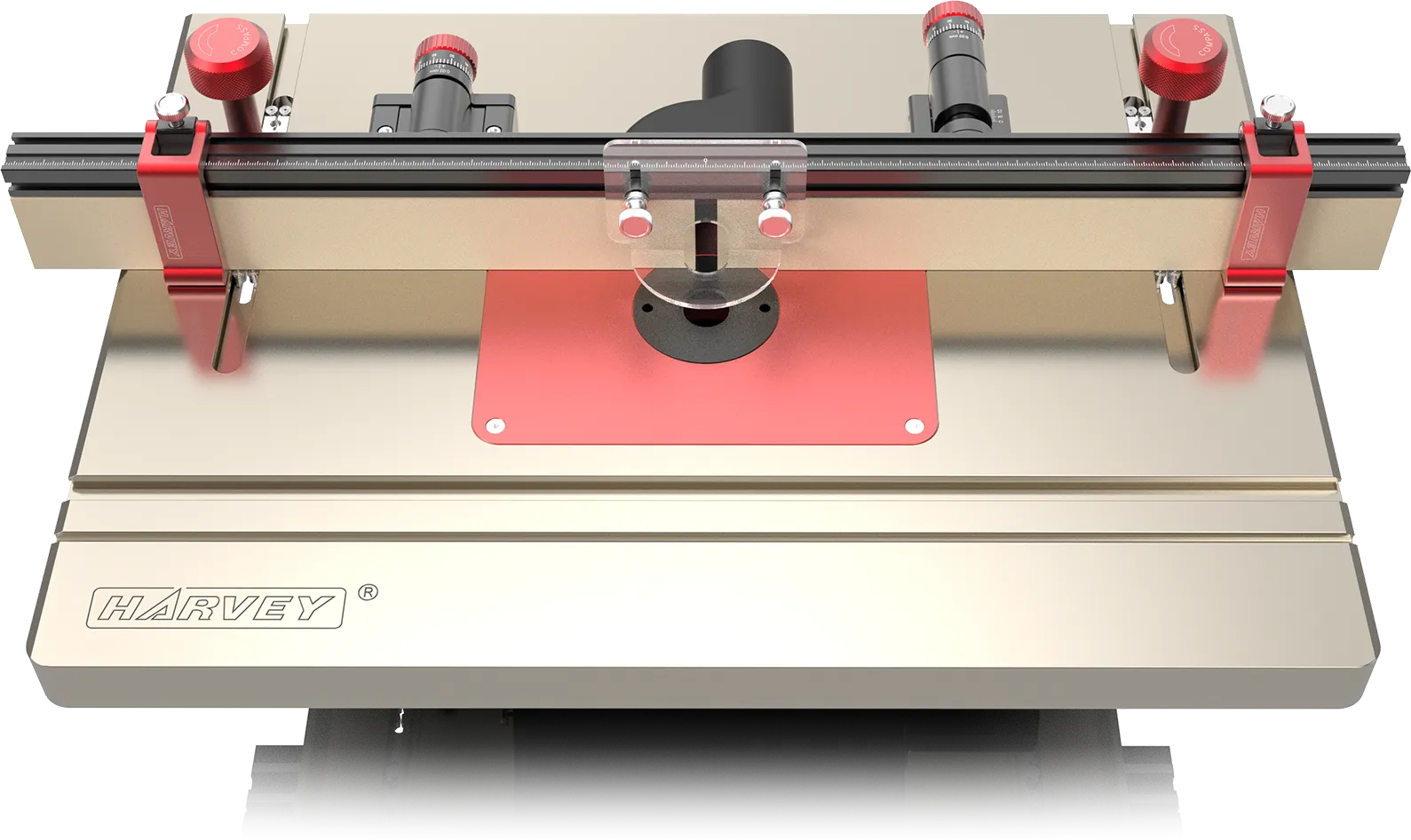

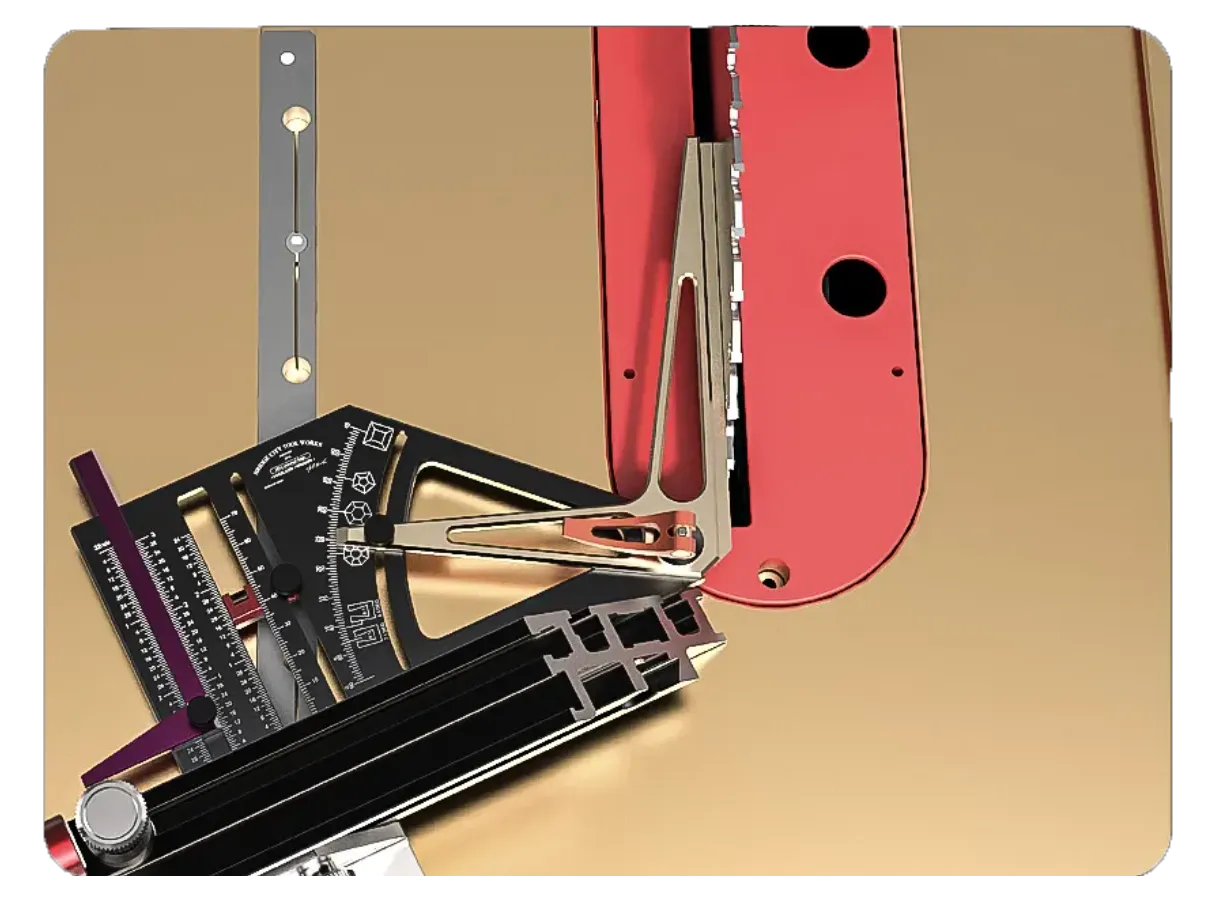

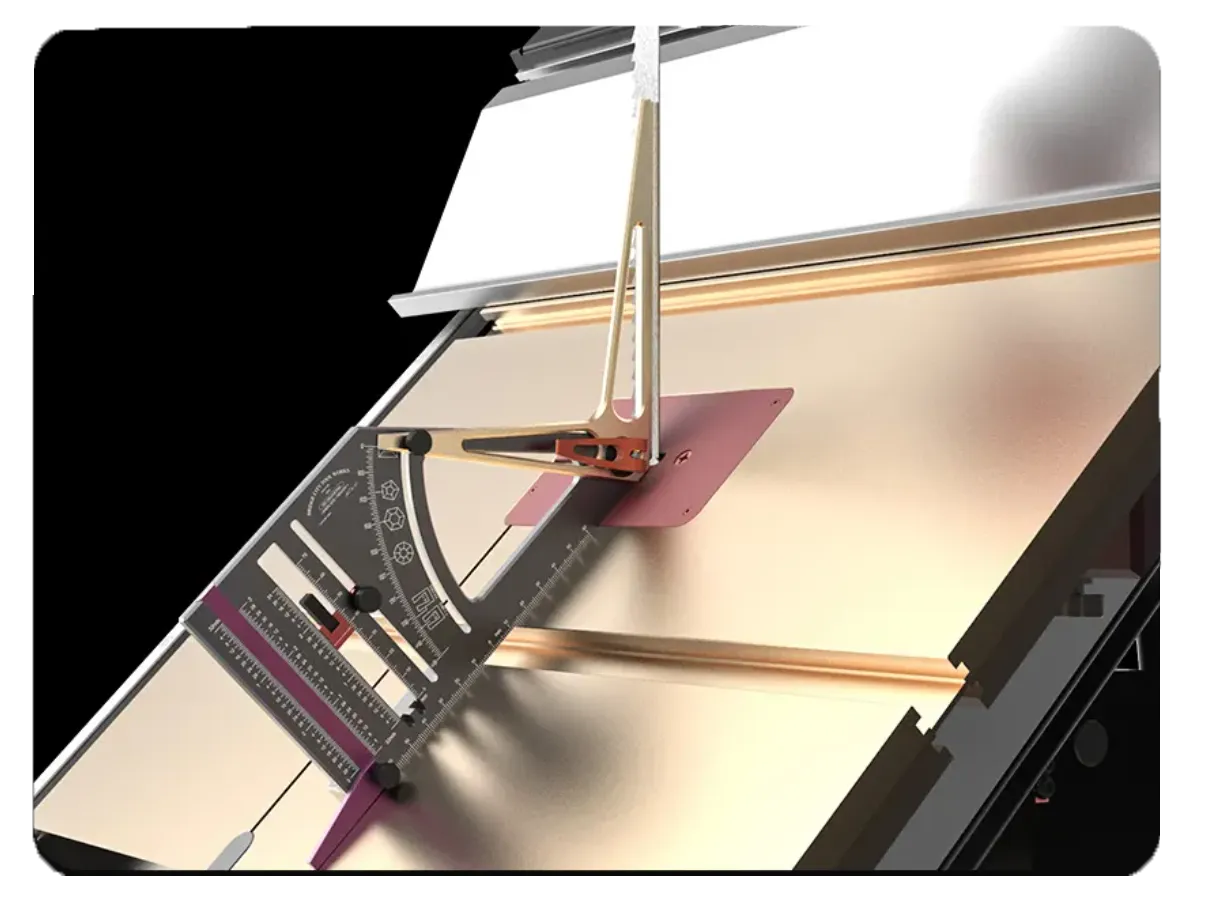

What is the COMPASS MG-36Pro Miter Gauge and why is it included?

The COMPASS MG-36Pro is a precision miter gauge made of T-6 aircraft-grade aluminum alloy with 0.1-degree angle setting accuracy. It features quick-action positive angle settings for ±60°, ±45°, ±30°, ±22.5°, ±15°, and 0° with single-handed operation. Includes a 36" crosscut fence with accurate flip stop and locking knob.

Operation & Specifications

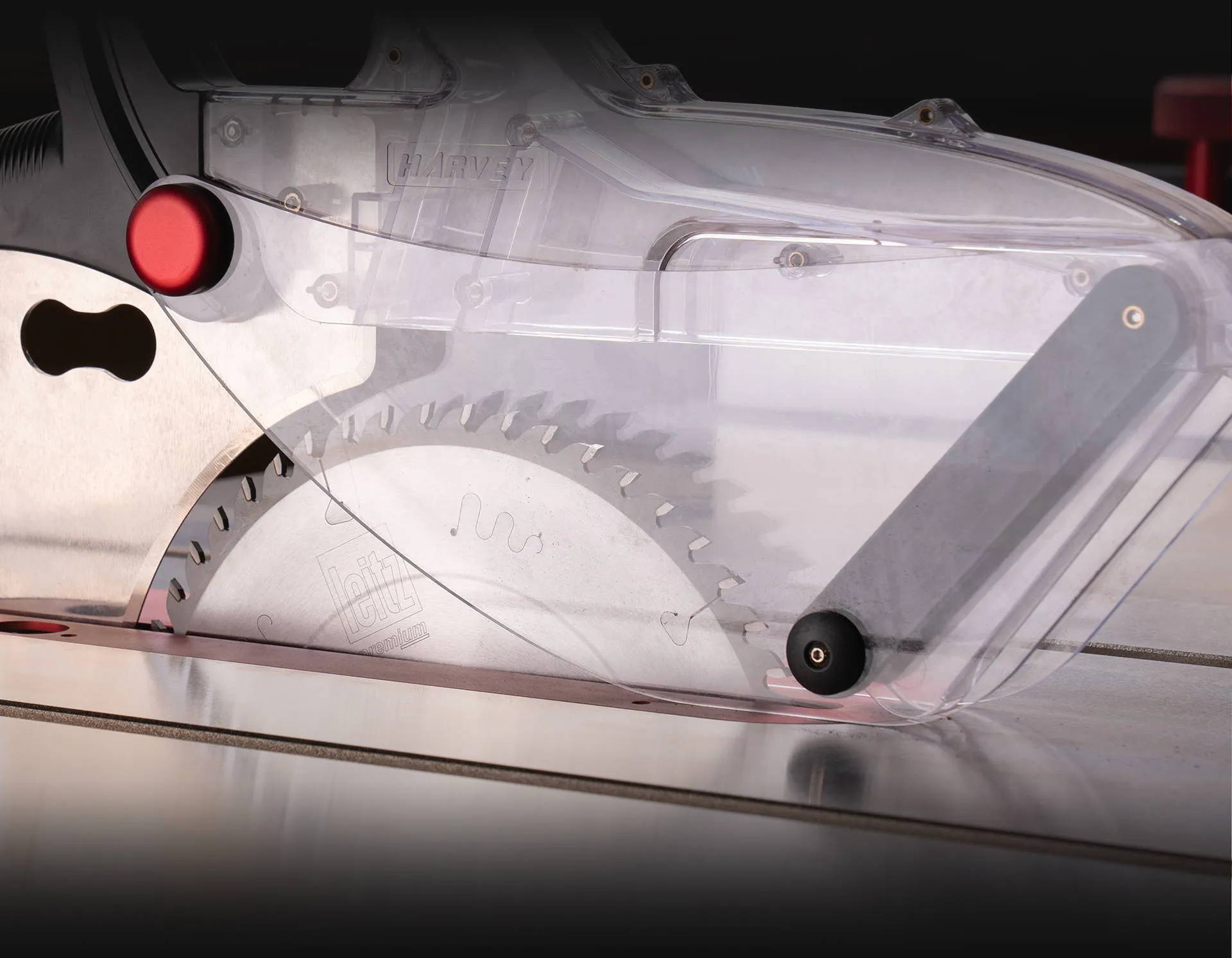

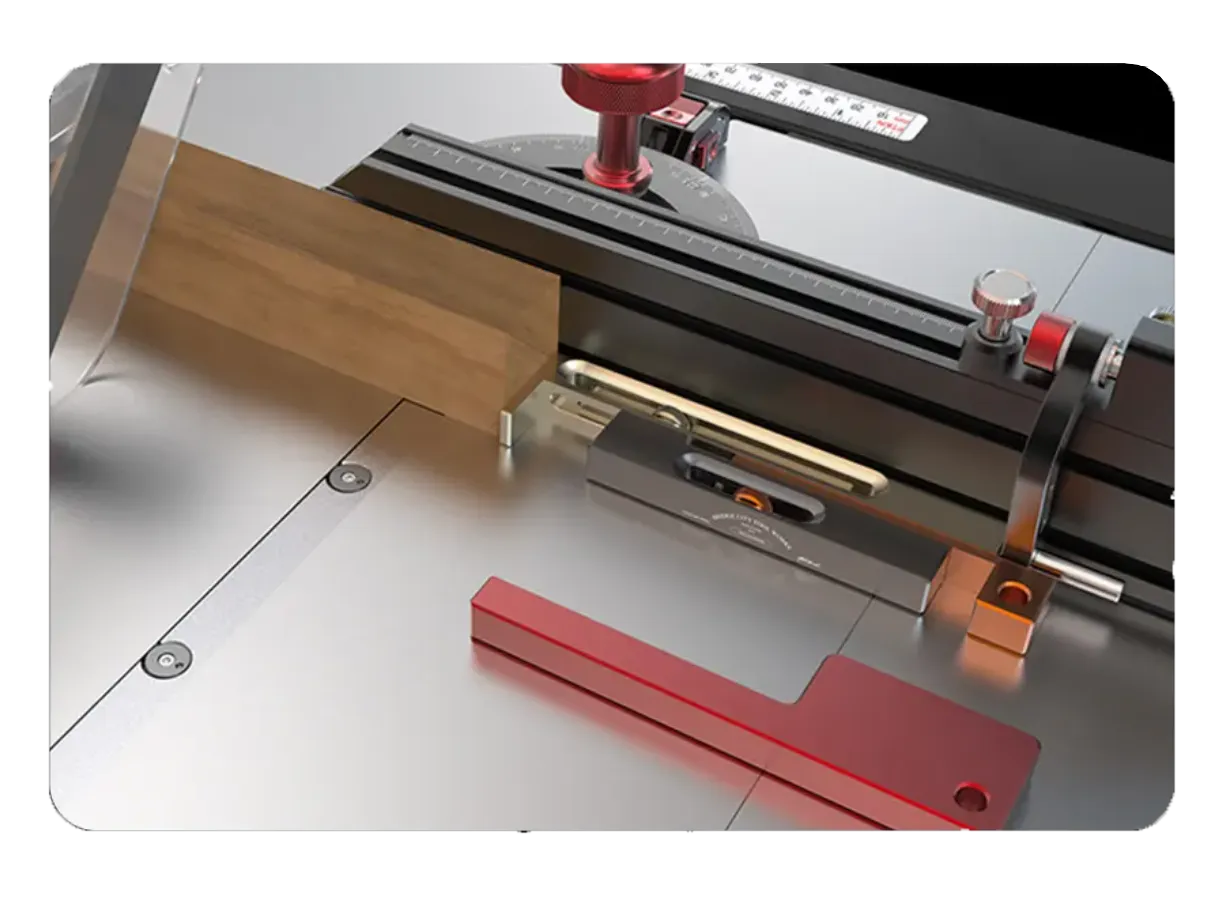

How does the K9 Crystal Glass Window work and what advantage does it provide?

The K9 Crystal Glass Window is a special scale viewer that boasts exceptional hardness and superior light transmittance, ensuring minimal visual errors (parallax) when reading measurements. It offers superior durability and resistance to wear compared to standard plastic scale viewers, providing more accurate fence positioning readings.

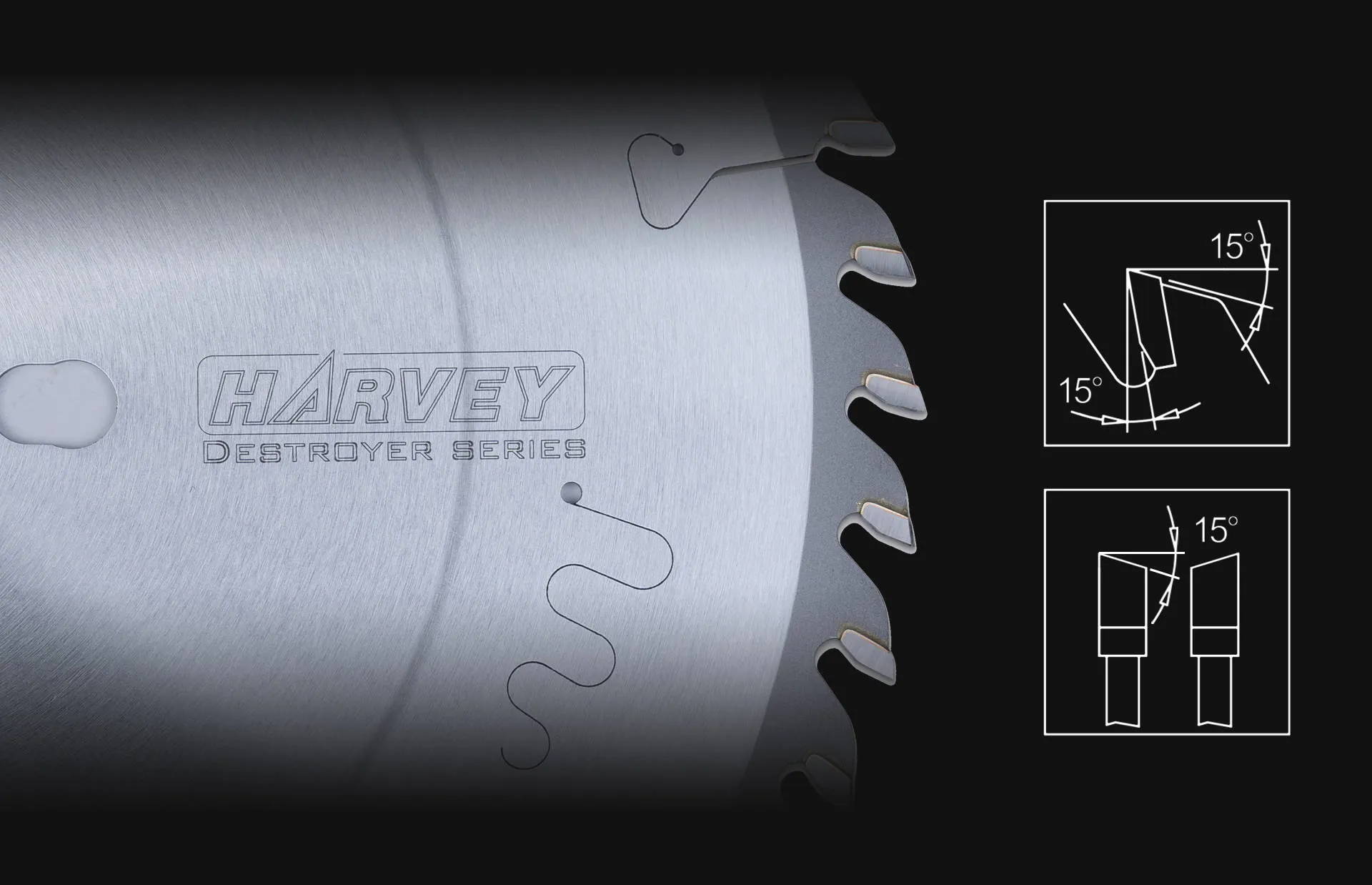

What are the cutting capacities and blade specifications?

Maximum depth of cut at 90°: 3-1/8" (79.4mm). Maximum depth of cut at 45°: 2-3/16" (55.5mm). Maximum rip capacity: 36" right, 9" left of blade. Uses 10" (254mm) blades with 5/8" arbor (North America) or 30mm/15.875mm arbor (Europe/Asia). Includes DESTROYER BG52 40-tooth general purpose blade.

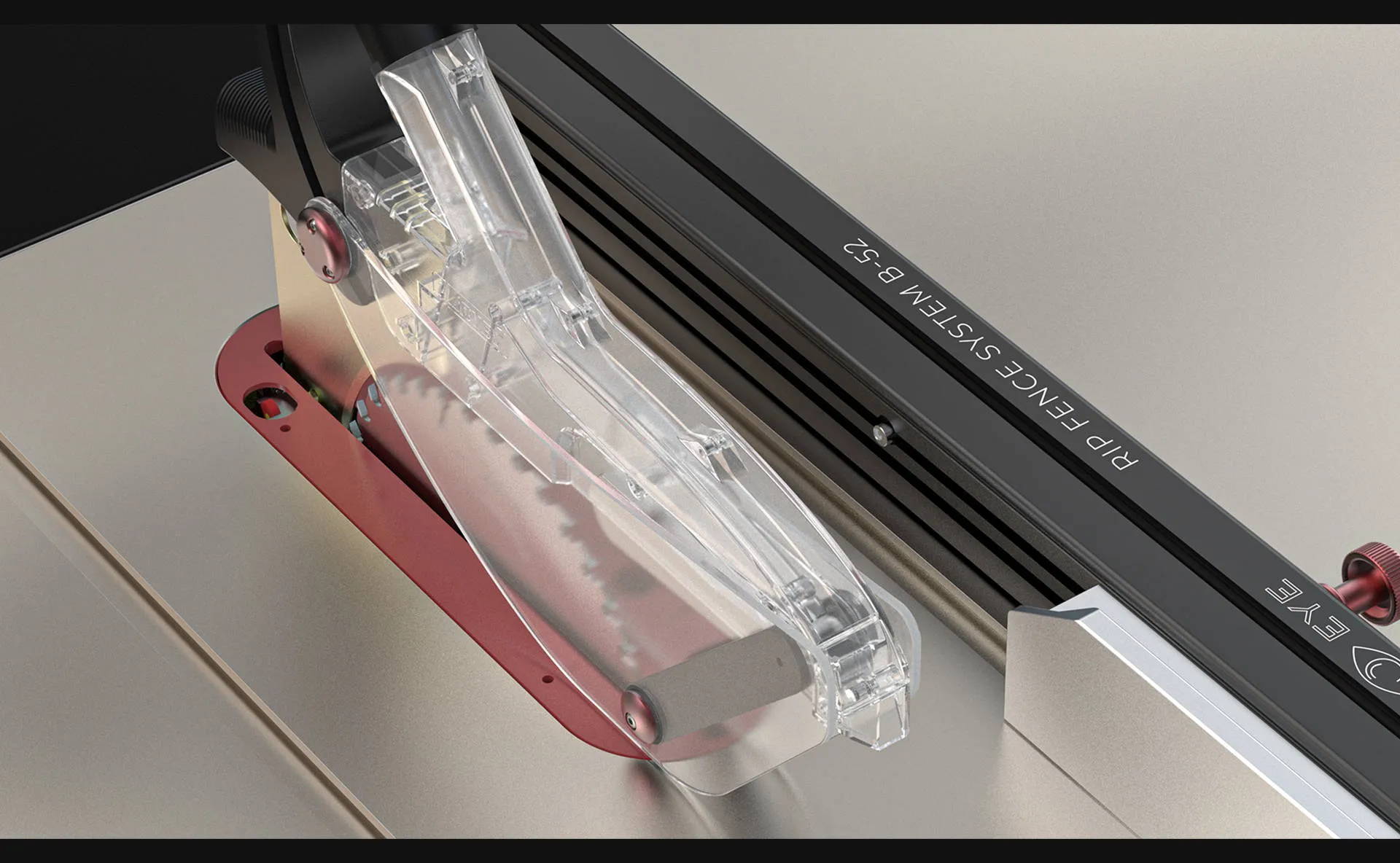

How does the quick-change system work for blade guards?

The patented "plug-in quick change" system allows blade guard and riving knife changes within seconds without removing the table insert. Simply slide the knurled knob, rotate to disengage, make changes, and re-engage the locking mechanism. This greatly improves workflow efficiency during blade changes.

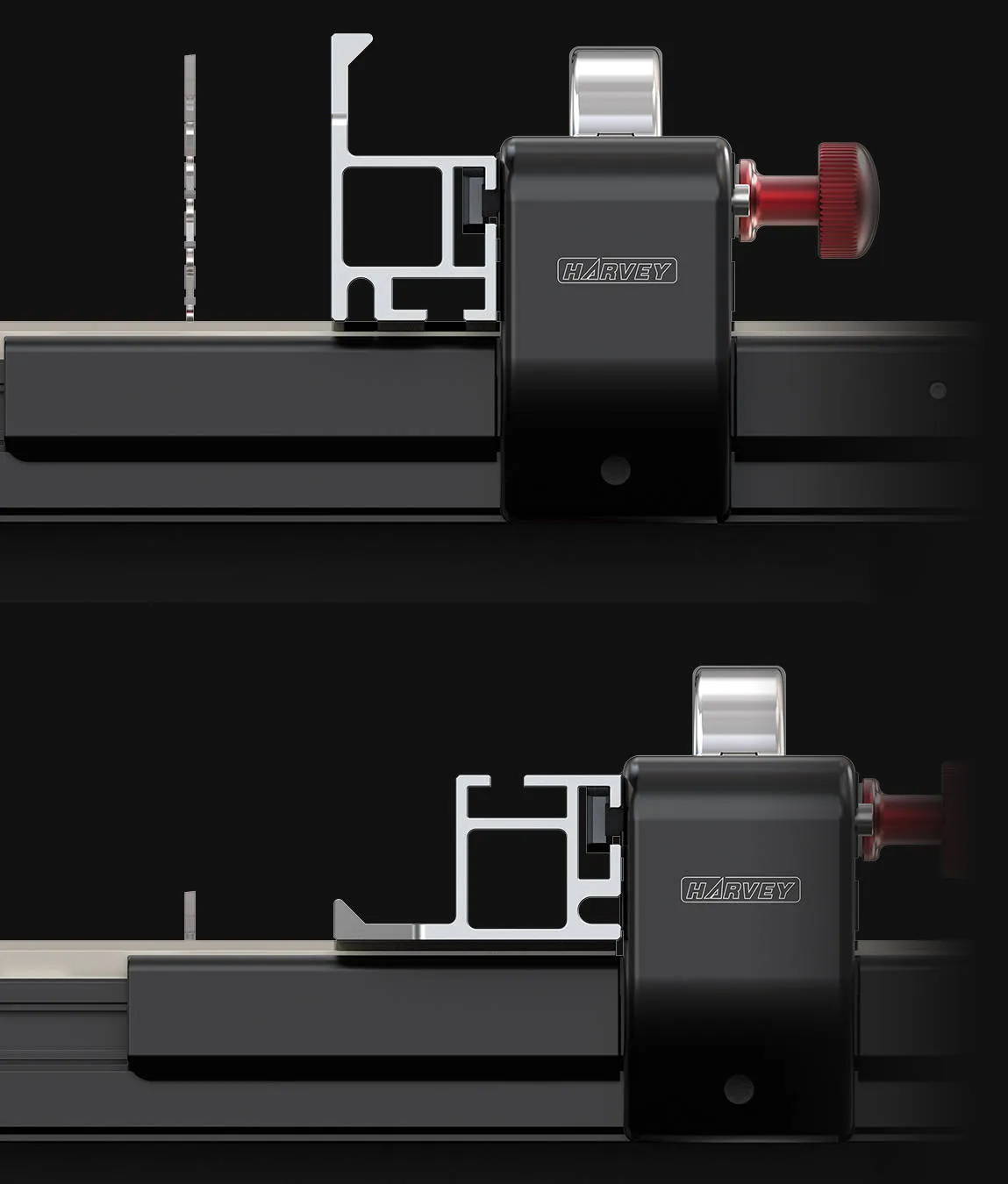

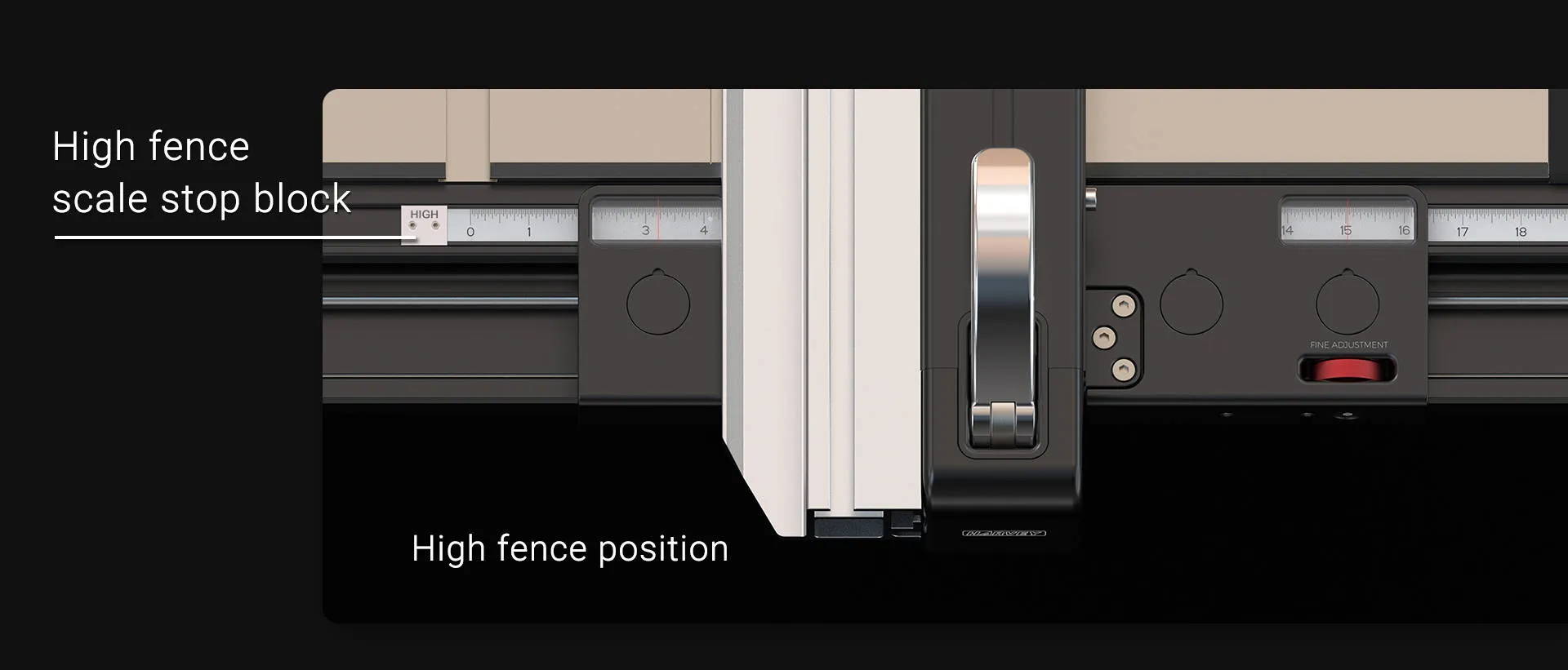

What is the difference between high and low fence positions?

The Big Eye Rip Fence System includes versatile high/low fence plates to accommodate different wood thicknesses. The high fence is designed for cutting thick wood, while the low fence is suitable for thin wood. Switching between positions is effortless with the sliding scale system.

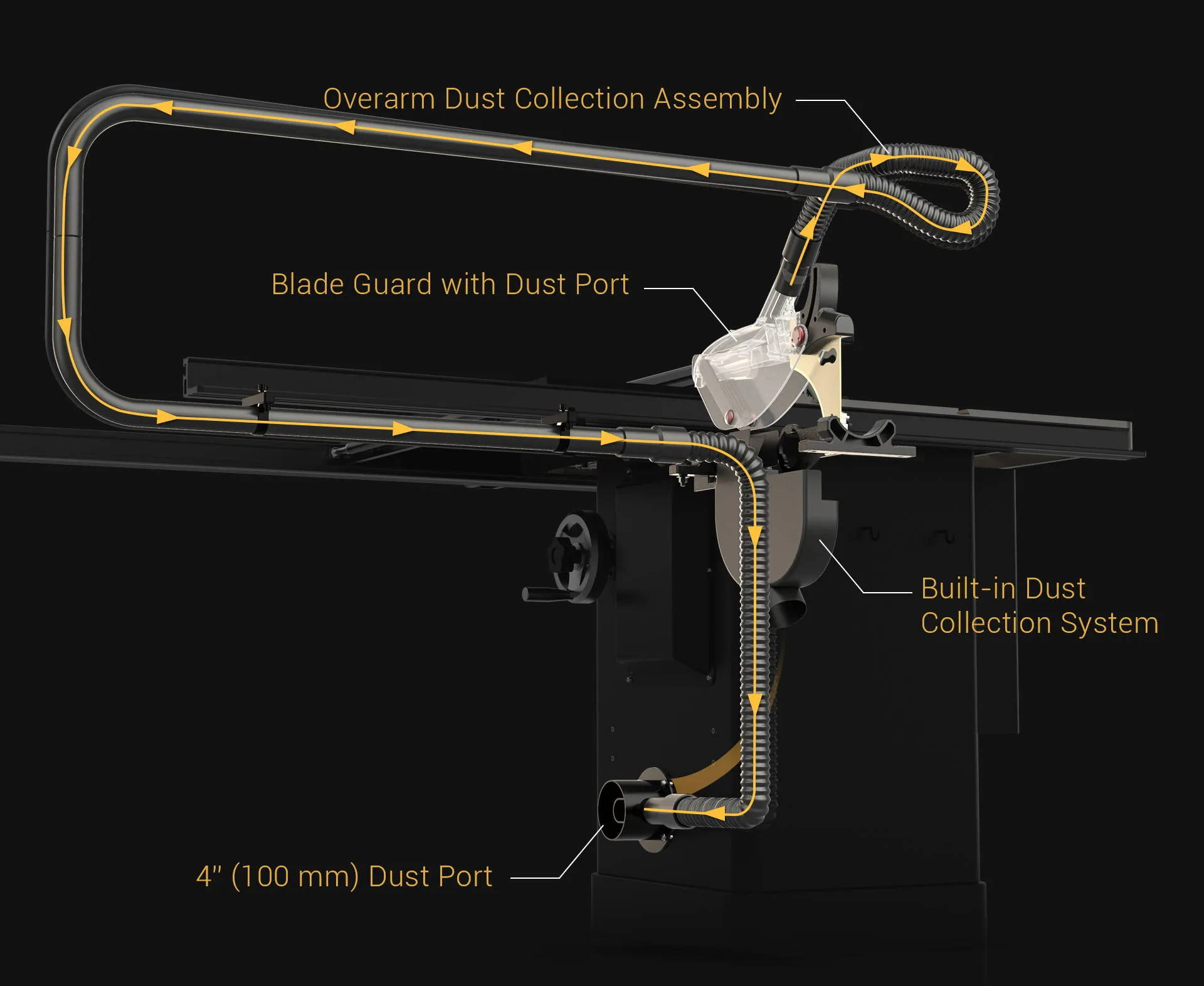

How does the dust collection system work and what are the requirements?

Features dual dust collection ports (upper and lower) requiring a dust collection system with minimum 470 CFM (800 m³/h) capacity. The system uses 4" (100mm) ports. Required pressure drop: 1100Pa per outlet. Air current speed requirements: 3937 FPM (20 m/s) for dry chips, 5511 FPM (28 m/s) for wet chips (18% water content). Includes over arm dust collection with flexible hoses (0.6m and 1m lengths). The GLIDER blade guard features aerodynamic optimization to improve dust collection efficiency.

Technical Specifications & Setup

How long does the nickel plating last and what happens if it gets damaged?

Under normal usage conditions, the nickel-plated surfaces maintain rust prevention performance for years, even in highly humid working environments. The coating achieves 500-700HV hardness for extreme durability. High-temperature and strong acid corrosion tests confirm exceptional longevity. If damaged, professional re-plating would be required.

Can the Alpha HW110LC-36Pro handle both precision and production work effectively?

Yes, the 2HP TEFC motor and precision construction handle both applications effectively. The Big Eye Rip Fence System provides production-level accuracy (0.02mm when locked), while the COMPASS MG-36Pro miter gauge ensures precision crosscuts. The extended table surface supports large production workpieces.

How difficult is assembly and are professional setup services available?

Partial assembly required including: extension wing mounting, rail installation, fence setup, blade guard installation, and electrical connections. The saw comes largely pre-assembled. Detailed instructions with diagrams are provided. Professional electrical installation may be required for power connections.

What accessories are included vs. what needs to be purchased separately?

Included: Cabinet saw unit, Big Eye Rip Fence System, COMPASS MG-36Pro miter gauge, DESTROYER BG52 10" 40T blade, blade guard assembly (GLIDER or CE version), dust port, hand wheels, hex wrench set (8 pieces), open-end wrench 13/27mm, push stick, dado table insert, over arm dust collection with flexible hoses, left extension wing. Separate purchases: Additional blades, sliding table (ST-1400S), overhead guard (S-12S), mobile base (MB-600), rear table extension (RT-10A).

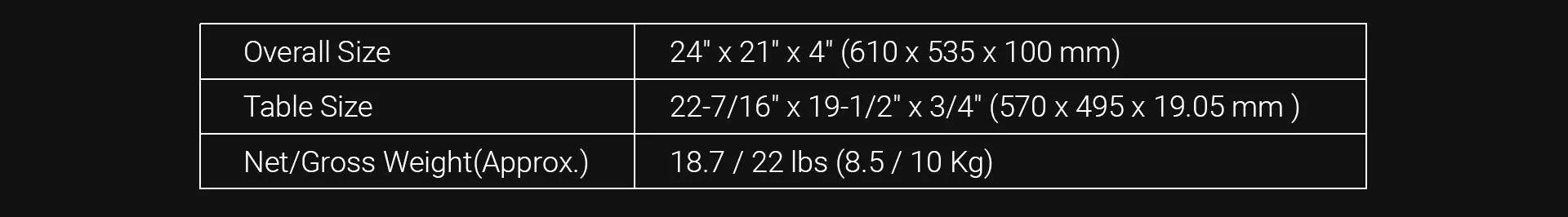

What is the difference between the Alpha HW110LC-36Pro and other Harvey cabinet saw models?

The HW110LC-36Pro features the revolutionary nickel plating technology on table and trunnion system, the advanced Big Eye Rip Fence System with K9 crystal glass window, and the COMPASS MG-36Pro miter gauge. The "Stain-less" designation refers specifically to the rust-prevention technology.

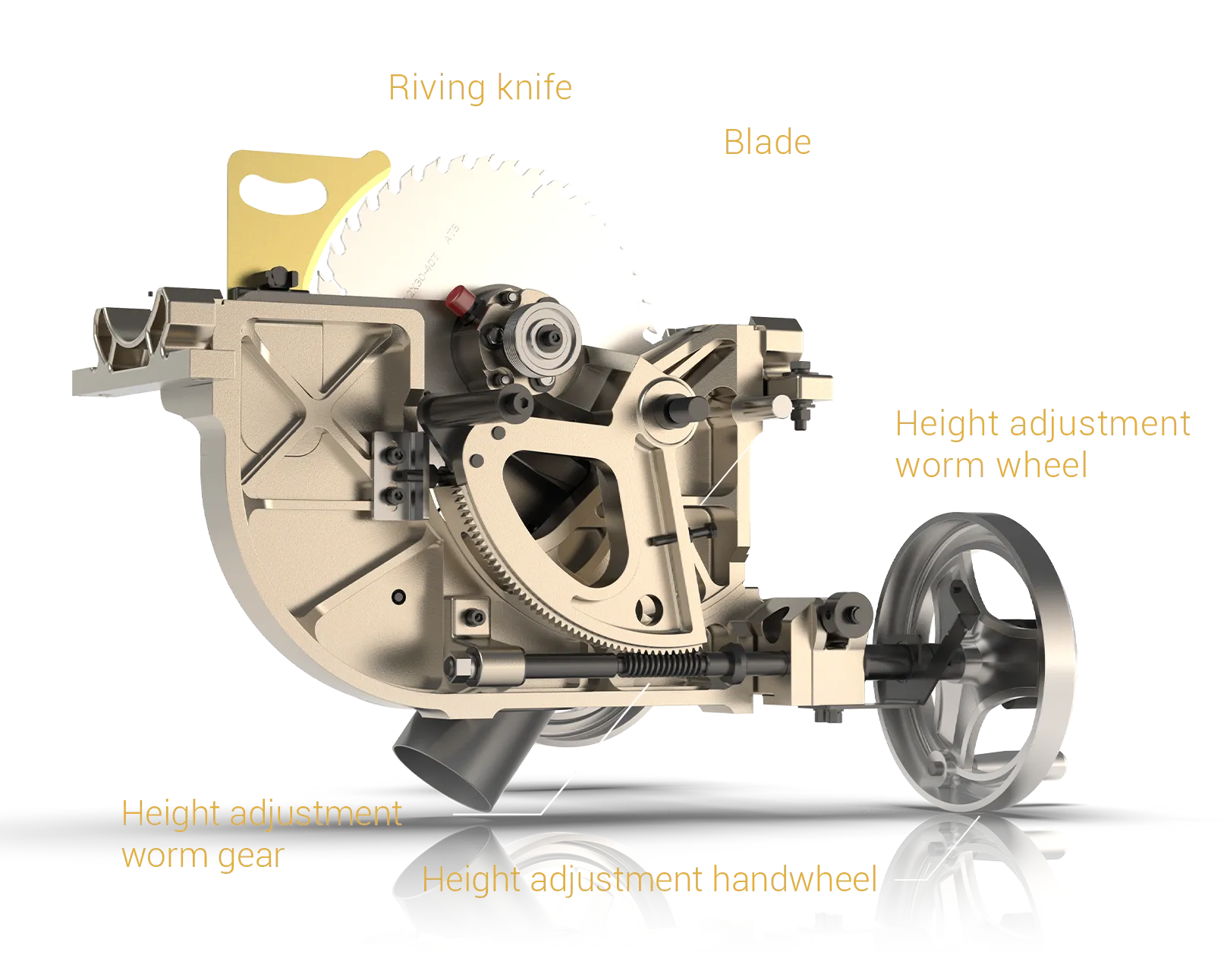

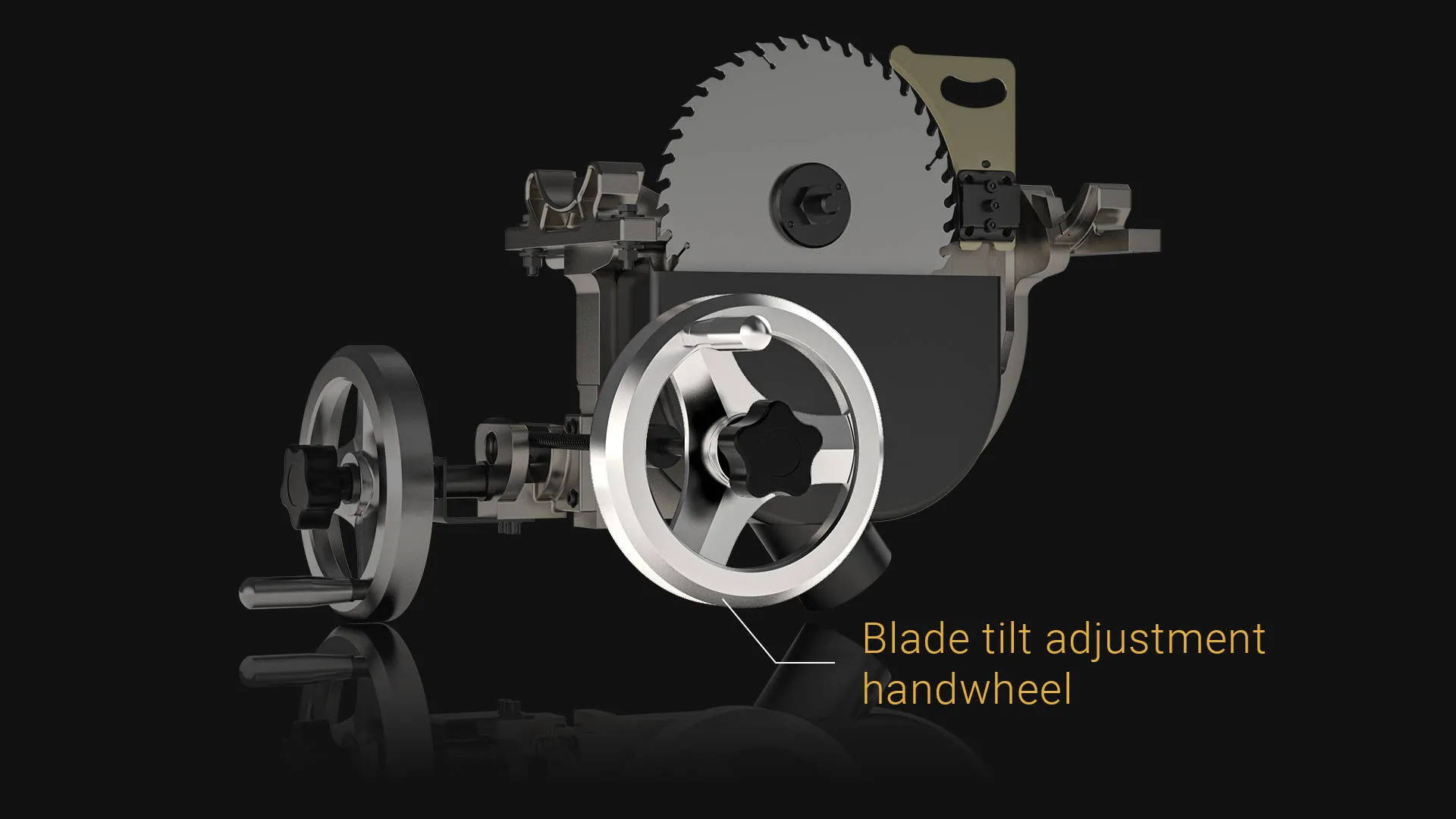

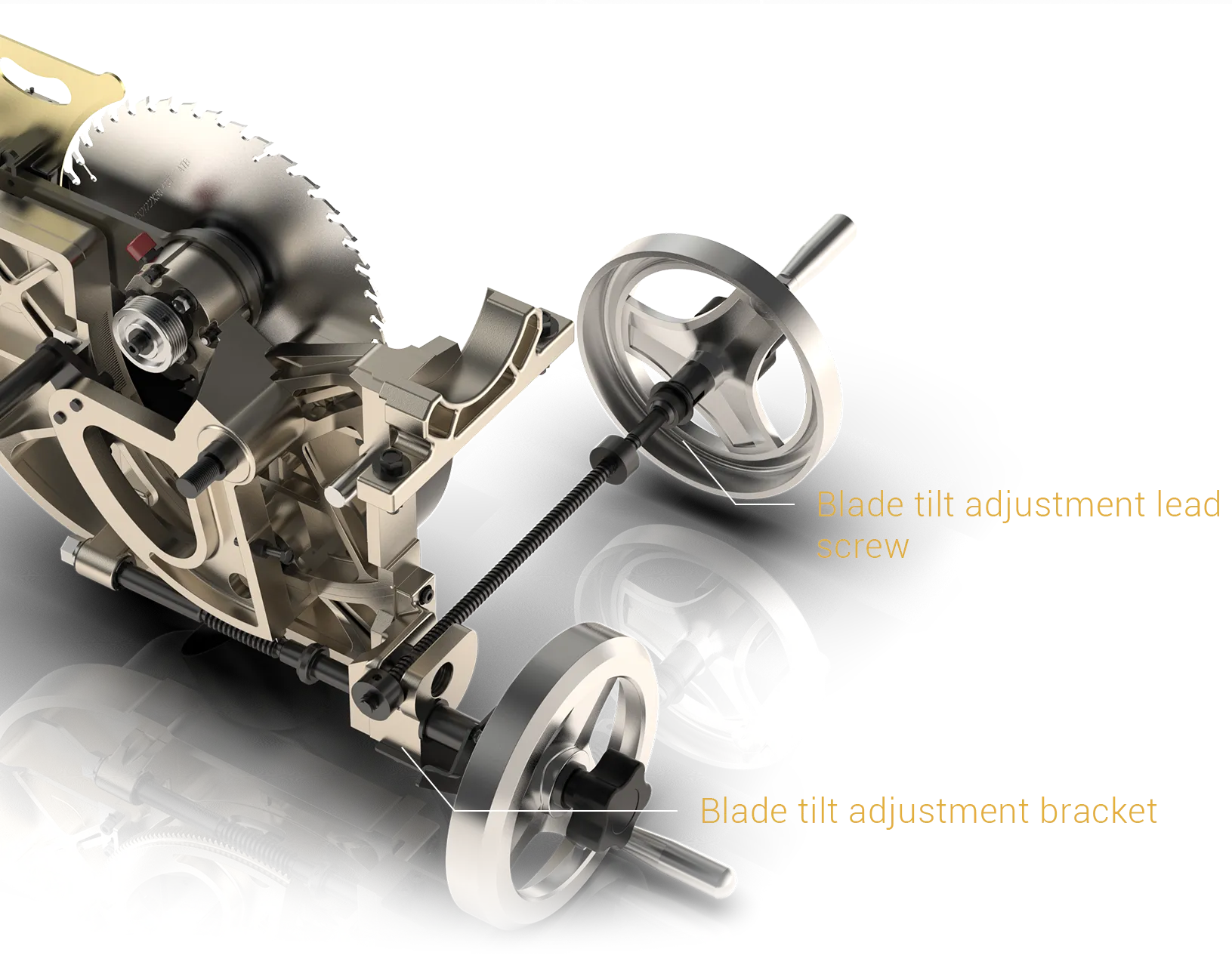

Can the blade be tilted and how precise is the adjustment?

Yes, the blade tilts left 0-45° controlled by a hand wheel and worm gear trunnion system. Features adjustable positive stops for 90° and 45° positions. The nickel-plated trunnion system ensures smooth, precise adjustments with minimal backlash for accurate bevel cuts.

What blade sizes are compatible and are replacement blades readily available?

Uses standard 10" (254mm) diameter blades. North American models use 5/8" arbor, while European models use 30mm arbor and Asian models use 15.875mm arbor. Available blade plate thickness: 0.071"-0.094" (1.8-2.4mm). Standard table saw blades are readily available from multiple suppliers.

How quiet is the Alpha HW110LC-36Pro compared to other 2HP cabinet saws?

The TEFC motor design, cabinet construction, and precision engineering contribute to quieter operation compared to open-stand saws. The substantial weight (411 lbs) and cabinet design help absorb vibration and reduce noise transmission.

Safety Questions

What safety equipment should I wear when operating the Alpha HW110LC-36Pro?

Always wear safety glasses and hearing protection. Remove loose clothing, ties, jewelry, and confine long hair. Use non-slip footwear. Remove gloves when operating (except when handling blades). Keep push sticks and push blocks readily available for narrow cuts.

How close should blade guards be positioned during operation?

The GLIDER blade guard automatically adjusts to workpiece thickness with side barriers. The riving knife should be positioned 3-8mm from the blade. Always ensure guards are in place for through-cutting operations. Use appropriate guards for dado operations.

What should I do if the blade binds during a cut?

Turn off the power immediately and wait for complete blade stoppage before attempting to free bound material. Check fence alignment, blade sharpness, and ensure workpiece isn't warped. Never attempt to back out material while blade is running.

Can I leave the Alpha HW110LC-36Pro running unattended?

Never leave the machine running unattended. Turn off power and wait for complete blade stoppage. The magnetic switch includes thermal overload protection, but personal supervision is always required during operation.

How should I properly feed material to avoid kickback?

Hold workpiece firmly against the fence and table. Feed at a steady pace without forcing. Use push sticks for narrow pieces (less than 4-3/4"). Never stand directly behind the blade. Ensure the riving knife is properly aligned and the blade is sharp.

What precautions should I take when changing blades?

Disconnect power source. Wear safety glasses and gloves when handling blades. Use an arbor lock pin to secure the shaft. Ensure blade teeth face forward direction. Verify proper tightening of the arbor nut. Check the riving knife alignment after blade changes.

Is it safe to make dado cuts on this cabinet saw?

Yes, maximum dado width is 13/16" (20.6mm). Use the included dado table insert. Remove blade guard for dado operations but maintain proper feeding techniques. Use featherboards and push sticks for control. Consider an overhead guard for added protection.

What electrical safety requirements does this cabinet saw have?

Requires proper grounding with 20A circuit breaker and RCD module for electrical shock protection. North American models use NEMA 5-20P (115V) or 6-20P (230V) plugs. All electrical connections must be made by qualified electricians following local codes.

How should I position my hands and body when operating the saw?

Keep hands away from the blade path. Stand to the side of the blade, not directly behind. Use push sticks and push blocks to keep hands safe distance from the blade. Maintain proper footing and balance. Never reach over or behind a spinning blade.

Product Specification Questions

What are the complete motor specifications for the Alpha HW110LC-36Pro?

North America: 2HP TEFC capacitor start induction motor, 115V (16A) or 230V (8A), 1PH, 60Hz, 3500 RPM motor speed, 3850 RPM arbor speed. Europe/Asia: 1.65kW TEFC capacitor start induction motor, 220V (10A), 1PH, 50Hz, 2900 RPM motor speed, 3850 RPM arbor speed. Requires 20A circuit breaker with RCD module.

What are the exact table dimensions and construction details?

Main table: 31.49" × 22.44" × 1.83" thick (800×570×46.5mm). Table height: 34" (867mm). Distance from front edge to blade center: 18.9" (480mm). Construction: precision ground cast iron with nickel plating, powder coated finish.

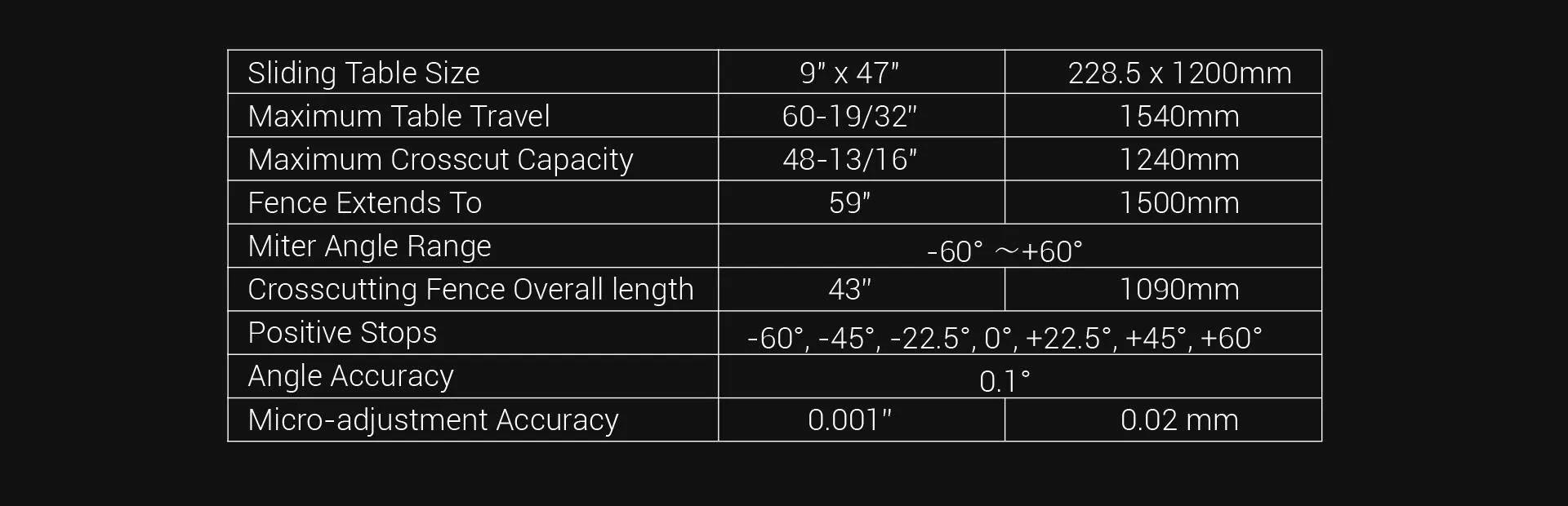

What are the Big Eye Rip Fence System complete specifications?

Fence size: 3-3/8" × 1-7/8" (85.5×48.5mm). Maximum rip capacity: 36" right, 9" left. Accuracy: 0.15mm movement accuracy, 0.02mm locked accuracy. Features: dual-axis linear guide with 8 bearing rollers, K9 crystal glass scale viewer, micro-adjustment knob, 4 flip position stops.

What are the dust collection system specifications and requirements?

Dual port system (upper and lower) with 4" (100mm) diameter ports. Required dust collector capacity: minimum 470 CFM (800 m³/h). System pressure requirements: 1100Pa pressure drop. Includes flexible hoses and aerodynamically designed GLIDER guard for improved collection efficiency.

What are the complete safety certifications and standards compliance?

UL62841 certified for the North American market. CE certified for the European market. TÜV Rheinland certified. Includes UL62841 compliant GLIDER blade guard for North America, CE version blade guard for Europe. Magnetic switch with thermal overload protection meets regional safety standards.

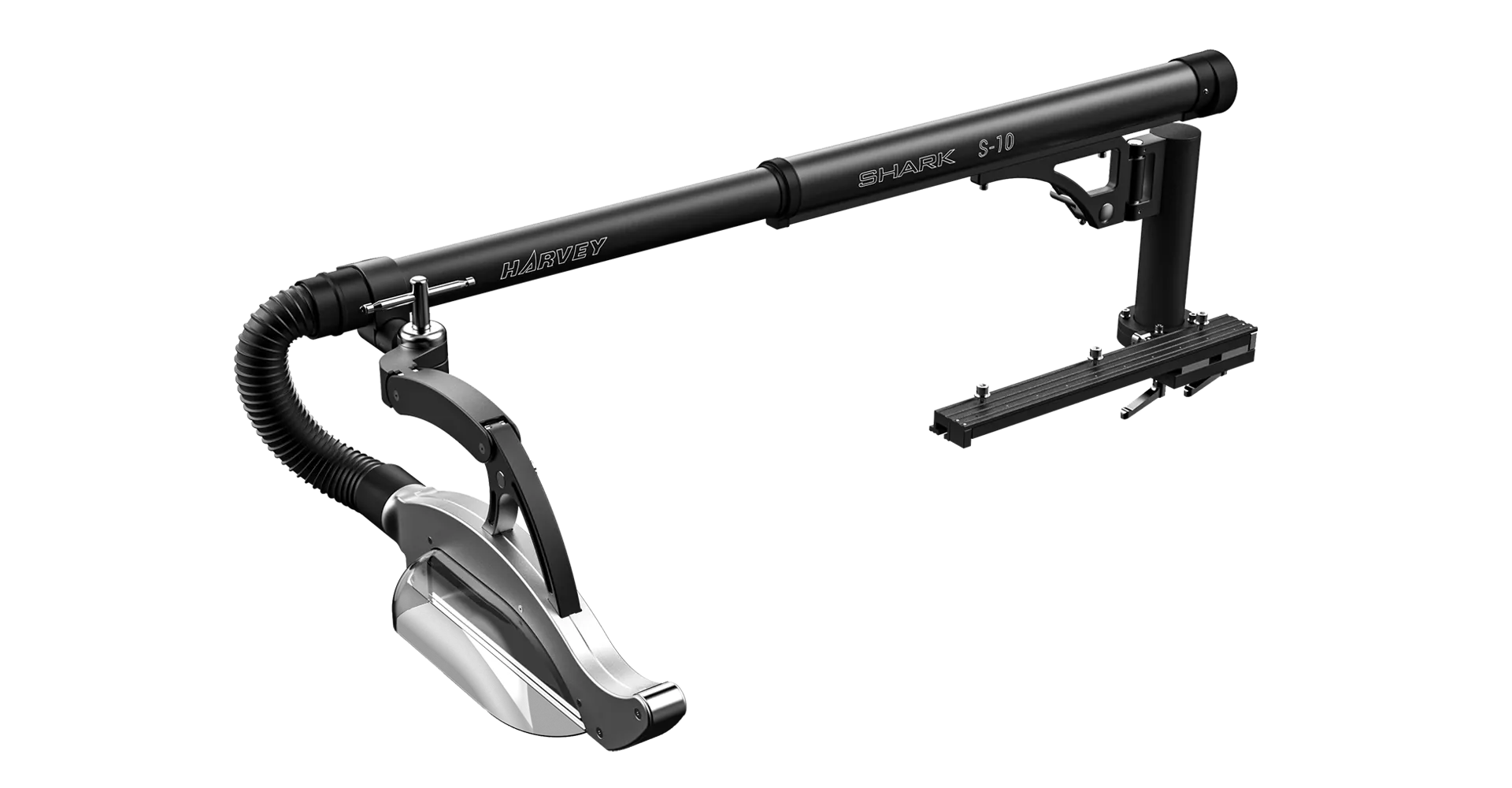

What optional accessories are available and their specifications?

ST-1400S Sliding Table: 1500mm/59" travel, industrial grade slider, stainless steel and aluminum construction. S-12S Universal Overhead Guard: tri-axis articulation, telescopic arm 39-3/8" to 62-19/32", air-spring mechanism. MB-600 Universal Mobile Base: supports cabinet weight, provides mobility.